Ductile Iron Rising Non-Rising Stem Resilient Seated cast iron gate valve,water gate valve

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 kg

- Supply Capability:

- 1000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Ball Valve Description:

Threaded ball valve is closed is a ball, ball around the center line of the body as a rotation to achieve a kind of open and close the valve.

Ball valve in the line is mainly used for cutting, distribution, and change the flow direction of medium. Two type ball valve, three type ball valve, is widely used in recent years a new type of valve, the valve average installation. And ball valve is a kind of ball valves, threaded pipe connection is screwed connection, and flanged ball valves, welded ball valve, etc.

2. Main Features of the Ball Valve:

• Small flow resistance;

• Simple structure

• Small volume, light weigh

• Small volume, light weigh

• Easy to operate, open and close quickly, facilitate remote contro

• Easy maintenance, sealing ring, which generally remove easy to change

• Full open or full close, sphere and valve seat sealing surface and the dielectric isolation, medium through does not cause the valve sealing surface erosion.

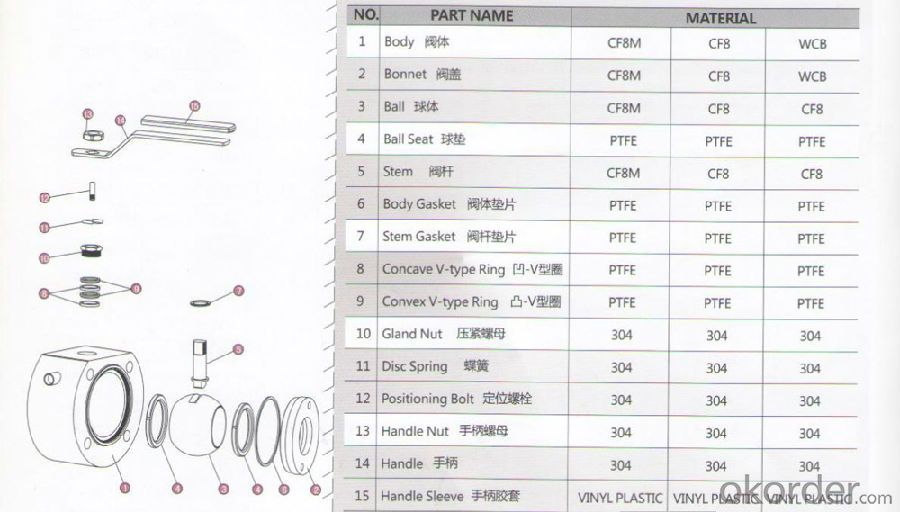

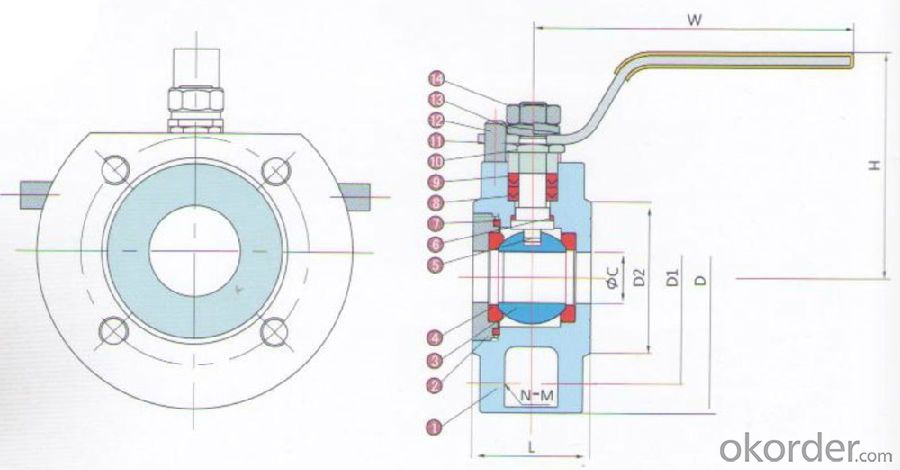

3. Images

4. Ball valve Specification

5.FAQ

1. What's are the characteristics of ball valve?

The distinct feature of a ball valve is the sealing surfaces between the gate and seats are planar, so ball valves are often used when a straight-line flow of fluid and minimum restriction is desired. The ball valve faces can form a wedge shape or they can be parallel.

2. What is the work principle of ball valve ?

The ball valve faces can form a wedge shape or they can be parallel. Ball valves are primarily used to permit or prevent the flow of liquids, but typical ball valves shouldn't be used for regulating flow, unless they are specifically designed for that purpose. Because of their ability to cut through liquids, ball valves are often used in the petroleum industry.

3. What is the structure?

Bonnets provide leakproof closure for the valve body. Ball valves may have a screw-in, union, or bolted bonnet. Screw-in bonnet is the simplest, offering a durable, pressure-tight seal. Union bonnet is suitable for applications requiring frequent inspection and cleaning. It also gives the body added strength. Bolted bonnet is used for larger valves and higher pressure applications.

- Q: What is the main function of the valve?

- Valve is a control component in the fluid delivery system. It has the functions of closing, adjusting, guiding, preventing reverse flow, stabilizing voltage, shunting or overflow and releasing pressure.Valves used in fluid control systems, from the simplest stop valve to a very complex automatic control system used in a variety of valves, a wide range of varieties and specifications. Valves can be used to control air, water, steam, a variety of corrosive media, mud, oil, liquid metal and radioactive media and other types of fluid flow. The valve according to the material is divided into cast iron valves, cast steel valves, stainless steel valves (201, 304, 316), chrome molybdenum steel, chromium molybdenum vanadium steel valves, valve, dual phase steel valves, plastic valves, non-standard customized valve material etc..

- Q: How about the quality of FITOK valves?

- It's made in China. It's also made of foreign brands!Swagelok, Hoke, Parker, these three are foreign brands!

- Q: What do you mean by "P54" in the valve z962y-p54 100V?

- 1, P54 is the valve body temperature is greater than or equal to 545 degrees, 100V is 10Mpa, that is, 100 kilograms, the valve name on all.2, valve (Famen) is a fluid conveying system control components, with cut-off, regulation, diversion, and prevent reverse flow, voltage regulation, shunt or overflow, pressure relief and other functions. Valves used in fluid control systems, from the simplest stop valve to a very complex automatic control system used in a variety of valves, a wide range of varieties and specifications. Valves can be used to control air, water, steam, a variety of corrosive media, mud, oil, liquid metal and radioactive media and other types of fluid flow. The valve according to the material is divided into cast iron valves, cast steel valves, stainless steel valves (201, 304, 316), chrome molybdenum steel, chromium molybdenum vanadium steel valves, valve, dual phase steel valves, plastic valves, non-standard customized valve material etc..

- Q: What is the valve before and after the pump?

- Conventional setting, the pump is installed before and after the cut-off valve. As for the check valve, according to the need to decide whether to install, to see whether the occasion required to prevent backwater function.

- Q: What are the valve types H, F, and Y? What are the meanings of these 3 letters?

- Please refer to "JB/T308-2004 valve model preparation method"Sealing surface material codeH Cr13 stainless steelF fluoroplasticY cemented carbide

- Q: Which valve can play a good regulatory role?

- A wide range of valves, the function is different, although like conventional butterfly valve, ball valve can play a regulatory role, but their role is not linear, so if you need to adjust the precision of the valve, it is best to select the control valve.

- Q: The general signal valve installation, or other valve installation is not installed with the groove flange clamp hoop Yucca or direct way? What's the convenient way to install the following diagram? I don't understand. Neither groove, flange nor hoop. Thank you, sir!

- The installation of the signal valve is in accordance with GB50261-2005The 5.4.6 signal valve shall be installed on the pipe in front of the flow indicator, and shall not be less than 300mm from the flow indicator.The other valve control valve installation, specification, type and location of installation shall comply with the design requirements, the installation direction should be correct, control valve should be clean, no blockage, no leakage; the main control valve should be added headstock logo, the control valve cover shall be provided to indicate position of the mark in the position.1. The installation of the exhaust valve shall be carried out after the pressure test and the flushing of the system pipe. The exhaust valve shall be installed at the top of the water distribution dry pipe and the end of the distribution pipe, and no leakage shall be ensured.2, the valve flow direction should be consistent with the direction of flow in the water supply pipe, water inlet side of the filter is installed, and should be installed in the control valve; the adjustable valve should be installed horizontally, the valve cover should be upward; the proportional valve should be installed vertically: when the level of installation, the valve orifice hole single breath we should double down, breathing valve whose orifice should be in a horizontal position.3 other control valve should be installed to keep a certain distance, to facilitate maintenance and management, installation of multifunctional pump control valve itself with pressure gauge, pressure gauge should be installed in the adjacent parts; import should be prevented in the back before the installation or use of the filter with filter backflow preventer, backflow preventer at both ends the valve should be installed separately, and at least one end of the flexible joint should be installed;

- Q: Where is it installed, what is the role, what is the material, and are there other alternatives instead of this effect?

- Valve packing in the valve under the gland to prevent leakage, you can use ordinary asbestos rope and butter emergency replacement

- Q: How to better maintain the valve?

- We should keep the valve cleanWe should regularly check and maintain the integrity of the valve the other components. As a fixed hand wheel nut fell off, to be filled and can not manage, otherwise it will grind the valve stem upper garden square, gradually lost with the reliability, and even can not startWe do not rely on the valve support other heavy objects, do not stand in the valveThe stem, especially the threaded part, to regular cleaning, the dust has been soiled should be replaced with a new lubricant, because the dust contains hard debris, easy to wear thread and stem surface, affect the service life

- Q: Valve legend

- F means a pressure gauge or thermometer; as to which type of valve, the marking should be a stop valve.

Send your message to us

Ductile Iron Rising Non-Rising Stem Resilient Seated cast iron gate valve,water gate valve

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 kg

- Supply Capability:

- 1000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords