Galvanized welded steel pipe for construction scaffolding

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 15000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1、Structure of Galvanized steel pipe for home decoration

The surface of galvanized steel pipe welded steel pipe of hot dip galvanized layer or. Galvanized can increase the corrosion resistance of the steel tube, prolong service life. Galvanized pipe is widely used, in addition to water, gas, oil and other general low pressure fluid pipelines. It is also used in the petroleum industry, especially for offshore oil field of oil well pipe and oil pipe, chemical, coking equipment of oil heater, condensation cooler, coal run oil exchanger tube, and trestle pile, the mine tunnel support frame tube.

2、Main Features of Galvanized steel pipe for home decoration :

• High manufacturing accuracy

• High strength

• Good visual effect

• Reasonable price

3、 Galvanized steel pipe for home decoration Specification:

Standard | GB, DIN, ASTM ASTM A106-2006, ASTM A53-2007 |

Grade | 10#-45#, 16Mn 10#, 20#, 45#, 16Mn |

Thickness | 1 - 33 mm |

Section Shape | Round |

Outer Diameter | 21 - 610mm |

Place of Origin | Tianjin, China (Mainland) |

Secondary Or Not | Non-secondary |

Application | Hydraulic Pipe |

Technique | Cold Drawn |

Certification | API |

Surface Treatment | factory state or painted black |

Special Pipe | API Pipe |

Alloy Or Not | Non-alloy |

Length | 5-12M |

Outer Diameter | 21.3-610mm |

Grade | 20#, 45#, Q345, API J55, API K55, API L80, API N80, API P110, A53B |

Standard | ASME, ASTM |

1) Material:Q195 Q235 Q345 X42 X52

2) Specification range:OD:21.3-610mm,WT:6-70mm,length:6-12m or according to the requirement of clients.

3) Excutive standards:GB,ASME API5L.ASTM A 106/A53,Despite of the above standards,we can also supply seamless steel pipe with standard of DIN,JIS,and so on,and also develop new products according to the requirements of our clients!

4) Surface: galvanized.

5) Ends:Beveled or square cut,plastic capped,painted.

6) Packing:bundles wrapped with strong steel strip,seaworthy packing.

4、Packaging & Delivery

Packaging Details: | seaworthy package,bundles wrapped with strong steel strip |

Delivery Detail: | 15-30days after received 30%TT |

5、FAQ of Galvanized steel pipe for home decoration

①How is the quality of your products?

Our products are manufactured strictly according to national and internaional standard, and we take a test

on every pipe before delivered out. If you want see our quality certifications and all kinds of testing report, please just ask us for it.

Guaranteed: If products’ quality don’t accord to discription as we give or the promise before you place order, we promise 100% refund.

②How about price?

Yes, we are factory and be able to give you lowest price below market one, and we have a policy that “ for saving time and absolutely honest business attitude, we quote as lowest as possible for any customer, and discount can be given according to quantity”,if you like bargain and factory price is not low enough as you think, just don’t waste your time.Please trust the quotation we would give you, it is professional one.

③Why should you chose us?

Chose happens because of quality, then price, We can give you both.Additionally, we can also offer professional products inquiry, products knowledge train(for agents), smooth goods delivery, exellent customer solution proposals.Our service formula: good quality+good price+good service=customer’s trust

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem.

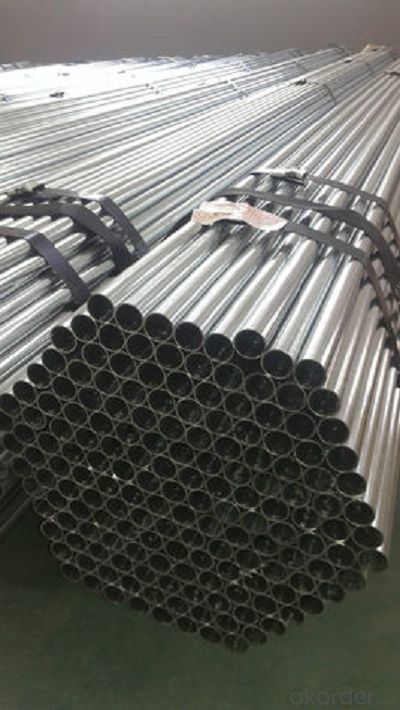

6、 Galvanized steel pipe for home decoration Images:

- Q: How do you determine the maximum allowable stress for a steel pipe?

- Several factors need to be taken into account in order to determine the maximum stress that a steel pipe can withstand. The type of steel used in the pipe is of utmost importance, as different types have varying mechanical properties and strengths. Additionally, the dimensions and thickness of the pipe are significant factors in determining its maximum stress capacity. Generally, thicker pipes have higher stress limits compared to thinner ones. Furthermore, it is crucial to consider the operating conditions that the pipe will be exposed to. This includes the temperature, pressure, and the nature of the fluid flowing through the pipe. These conditions can greatly impact the maximum stress that the pipe can tolerate. For instance, high temperatures or corrosive fluids can weaken the steel and reduce its strength. Engineers typically rely on industry standards and codes, such as the ASME Boiler and Pressure Vessel Code and the API standards, to determine the maximum stress limit. These standards provide guidelines and formulas for calculating the maximum stress based on the material properties, dimensions, and operating conditions of the pipe. It is important to emphasize that determining the maximum stress limit is a critical step in ensuring the structural integrity and safety of the steel pipe. It requires a comprehensive understanding of the materials, design considerations, and industry standards. Therefore, it is advisable to seek guidance from experienced engineers or professionals who specialize in piping design and analysis to accurately determine the maximum stress that a steel pipe can withstand.

- Q: What's the difference between round and round tubes?

- Round steel is a medium solid steel, of course the tube is hollow

- Q: What are the different methods of coating steel pipes for insulation?

- Insulating steel pipes can be achieved through various methods, each with its own pros and cons. 1. One method involves applying a layer of thermal insulation material, like mineral wool or foam, onto the steel pipes. This helps minimize heat transfer and energy loss. While these coatings are easy to apply and offer excellent insulation properties, they are prone to degradation over time and require regular maintenance and replacement. 2. Another approach is to coat the steel pipes with materials that protect against corrosion, such as epoxy or polyethylene. These coatings act as a barrier, shielding the pipes from moisture, chemicals, and other corrosive elements. They are durable and long-lasting, providing effective protection. However, they may not offer significant thermal insulation. 3. Fusion-bonded epoxy (FBE) coating is a popular method that combines both insulation and corrosion protection. It involves applying a layer of epoxy powder to the pipes and heating it to create a strong bond. FBE coatings offer excellent adhesion, corrosion resistance, and some thermal insulation properties. They are commonly used in oil and gas pipelines, enduring harsh environments and high temperatures. 4. Polyurethane foam is often used as an insulation coating for steel pipes. It is applied by spraying or injecting the foam onto the pipe surface, where it expands and hardens, forming a protective layer. Polyurethane foam coatings provide exceptional thermal insulation and can be applied to pipes of different shapes and sizes. However, they require specialized equipment and expertise and may be susceptible to physical damage or moisture absorption if not properly sealed. 5. Ceramic coatings offer yet another option for insulating steel pipes. These coatings are typically applied through a thermal spray process, creating a layer of ceramic material on the pipe surface. Ceramic coatings provide insulation against high temperatures, corrosion resistance, and thermal shock protection. They are commonly used in industries like power generation and aerospace, where extreme temperature conditions are present. However, ceramic coatings can be costly and require specialized equipment and expertise for application.

- Q: How do steel pipes compare to other types of piping materials?

- Steel pipes are widely considered to be one of the most durable and strong types of piping materials available. They offer superior strength, resistance to corrosion, and can withstand high pressure and extreme temperatures. Compared to other materials such as PVC or copper, steel pipes have a longer lifespan and are more suitable for heavy-duty applications. Additionally, steel pipes are highly recyclable, making them an environmentally friendly choice.

- Q: Can steel pipes be used for desalination plants?

- Yes, steel pipes can be used for desalination plants. Steel pipes are commonly used in desalination plants to transport and distribute water, as they are durable, resistant to corrosion, and can handle high-pressure systems.

- Q: What are the different grades of steel used for manufacturing pipes?

- The different grades of steel commonly used for manufacturing pipes include carbon steel, alloy steel, and stainless steel.

- Q: What are the different methods of pipe welding for steel pipes?

- There are several different methods of pipe welding for steel pipes, each with its own unique advantages and applications. Here are some of the most common methods: 1. Shielded Metal Arc Welding (SMAW): Also known as stick welding, SMAW is a manual welding process that uses a consumable electrode coated in flux. The electrode is melted to create the weld, and the flux creates a protective shield around the weld pool. SMAW is versatile and can be used in various positions, making it suitable for both field and workshop applications. 2. Gas Metal Arc Welding (GMAW): Commonly known as MIG (Metal Inert Gas) welding, GMAW uses a continuous wire electrode that is fed through a welding gun. The welding gun also supplies a shielding gas, such as argon or a mixture of argon and carbon dioxide, to protect the weld pool from atmospheric contamination. GMAW is known for its high welding speed and is often used in industrial applications. 3. Flux-Cored Arc Welding (FCAW): Similar to GMAW, FCAW uses a continuous wire electrode, but the wire is filled with flux instead of relying on an external shielding gas. The flux in the wire produces a protective shield around the weld pool, eliminating the need for a separate gas supply. FCAW is commonly used in outdoor and windy conditions as it provides better protection against atmospheric contamination. 4. Gas Tungsten Arc Welding (GTAW): Also known as TIG (Tungsten Inert Gas) welding, GTAW uses a non-consumable tungsten electrode to create the weld. The weld pool is protected by a shielding gas, typically argon, which is supplied separately. GTAW produces high-quality welds with excellent control, making it suitable for critical applications where precision is crucial. 5. Submerged Arc Welding (SAW): SAW is an automated welding process that uses a continuously fed wire electrode and a granular flux that is poured over the weld joint. The arc is submerged beneath the flux, providing excellent protection against contamination. SAW is commonly used in heavy fabrication and pipeline industries due to its high deposition rates and deep penetration capabilities. These are just a few of the different methods of pipe welding for steel pipes. The choice of method depends on factors such as the application, material thickness, desired weld quality, and available equipment. It is important to select the appropriate welding method to ensure strong, durable, and reliable welds in steel pipe applications.

- Q: What are the different methods of cutting steel pipes?

- There are several methods of cutting steel pipes, including manual methods such as hacksawing and pipe cutters, as well as more advanced methods like plasma cutting, oxy-fuel cutting, and bandsaw cutting. Each method has its own advantages and suitability depending on the specific requirements of the project.

- Q: What are the different standards for steel pipes?

- There are several different standards for steel pipes that are used to ensure quality and compatibility in various applications. Some of the most commonly used standards include: 1. ASTM (American Society for Testing and Materials): ASTM standards are widely used in the United States and provide specifications for various types of steel pipes, including seamless and welded pipes. These standards cover dimensions, mechanical properties, and general requirements for steel pipes. 2. API (American Petroleum Institute): API standards are specifically designed for oil and gas industry applications. These standards provide guidelines for the manufacturing, testing, and inspection of steel pipes used in the oil and gas exploration, production, and transportation sectors. 3. DIN (Deutsches Institut für Normung): DIN standards are widely used in Europe and provide specifications for various steel pipe types, including seamless, welded, and cast iron pipes. These standards cover dimensions, materials, and technical delivery conditions for steel pipes used in various industries. 4. BS (British Standards): BS standards are widely used in the United Kingdom and cover specifications for steel pipes used in construction, engineering, and other applications. These standards provide guidelines for dimensions, materials, and manufacturing processes for steel pipes. 5. JIS (Japanese Industrial Standards): JIS standards are widely used in Japan and cover specifications for various steel pipe types, including seamless, welded, and cast iron pipes. These standards provide guidelines for dimensions, materials, and technical delivery conditions for steel pipes used in various industries. 6. ISO (International Organization for Standardization): ISO standards are recognized globally and provide specifications for steel pipes used in various industries. These standards cover dimensions, materials, testing, and quality control requirements for steel pipes. It is important to note that different industries and applications may have specific requirements, and therefore, it is essential to refer to the relevant standard for each specific use case. Adhering to these standards ensures the safety, reliability, and compatibility of steel pipes in their respective applications.

- Q: Can steel pipes be used for heat transfer applications?

- Yes, steel pipes can be used for heat transfer applications. Steel is a good conductor of heat, making it suitable for transferring heat from one place to another. Steel pipes are often used in various heat transfer systems, such as in heating, ventilation, and air conditioning (HVAC) systems, as well as in industrial applications where heat needs to be transported efficiently.

Send your message to us

Galvanized welded steel pipe for construction scaffolding

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 15000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords