Galvanized Steel Sheet in Ciols with Prime Quality Best Seller

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

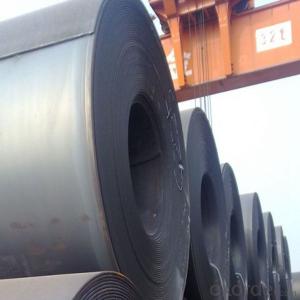

1.Structure of Galvanized Steel Coil Description:

Hot-dip galvanized steel coils are available with a pure zinc coating through the hot-dip galvanizing process. It offers the economy, strength and formability of steel combined with the corrosion resistance of zinc.

2.Main Features of the Galvanized Steel Coil:

• Good formability • Rust- proof ability • Good visual effect • Base material for countless outdoor and industrial applications

Zinc coating :40-180g( as required)

Coil id:508mm/610mm

Coil weight: 4-10 MT(as required)

Surface: regular/mini/zero spangle, chromated, skin pass, dry etc.

5.FAQ of Galvanized Steel Coil

We have organized several common questions for our clients,may help you sincerely:

1.How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

• High corrosion resistance

• High strength

3.Galvanized Steel Coil Images

4.Galvanized Steel Coil Specification

Width:914-1250mm(914mm, 1215mm,1250mm,1000mm the most common) Grade : SGCD,SGCH, Q195,DX51D

- Q: I need to know where to go online to buy a steel cage for a wrestling ring.. Somebody please assist me?

- the only thing you can find is a bird cage because their is no way you can buy a steel cage unless you build it yourself

- Q: Hi I was thinking about buying this knife, but i wasn't sure if it was good because it's stainless steel.

- This isn't really a question for this section, but I'm still happy to help out since I'm a big cutlery nerd as well. One thing to look out for when buying a knife is a lack of specifics on what steel is being used. High Carbon Stainless Steel doesn't tell you what the steel is, just what it MIGHT be. Chances are it's something along the lines of 420HC or 440A, both of which are softer steels. They aren't the worst steels around, but they are very quick to dull. You'd be better off looking at the Balisongs of Benchmade. They'll cost more, but you'll know that you're getting something made with quality materials and that won't break on you. And if it does break for some odd reason, Benchmade's warranty and customer service are both fantastic. Although if a more questionable knife is okay with you as long as the price isn't too high, then at least 420HC and 440A aren't too brittle and will take a decent edge even though they'll dull quickly. As for whether stainless steel is good for a knife or not, that depends on the type of stainless steel and what you're going to use the knife for. Many stainless steels are more brittle than a carbon steel, so high carbon stainless steels are a bit more likely to rust but a little tougher as well. In a butterfly knife, a steel like that is a good way to go, although the steels used by Benchmade, as I mentioned, are of a much better quality.

- Q: How are steel coils processed at the steel service centers?

- Steel service centers process steel coils through a series of steps to transform them into finished products that meet the specific requirements of customers. The process typically begins when the steel coils arrive at the service center. These coils are usually large and heavy, and they may have been produced by a steel mill or imported from overseas. Upon arrival, the steel coils undergo a quality inspection to identify any defects and ensure that only high-quality coils are used in the production process. After inspection, the coils are stored in a warehouse until they are ready for processing. Next, the steel coils are uncoiled to create flat sheets of steel. This can be done manually or using automated machines, depending on the size and thickness of the coils. The uncoiled steel is then leveled to remove any residual stress and ensure a flat and consistent surface. Once leveled, the steel sheets go through various processes based on the desired end product. These processes may include cutting, shearing, slitting, and forming. Cutting and shearing involve shaping the steel sheets into specific sizes or shapes. Slitting involves cutting the steel into narrow strips, while forming involves bending or shaping the steel. After the desired processing operations are completed, the steel sheets are often treated with surface finishes to enhance their appearance or protect them from corrosion. These finishes may include painting, coating, or galvanizing. Finally, the processed steel sheets undergo another quality inspection to ensure they meet the required specifications. They are then packaged and prepared for shipment to customers in industries such as construction, automotive, or manufacturing. Overall, the processing of steel coils at steel service centers involves a combination of inspection, uncoiling, leveling, cutting/shearing/slitting/forming, surface finishing, quality control, and packaging. This process allows for the transformation of steel coils into finished products that are customized to meet the specific needs and requirements of customers.

- Q: So finally got around to watching man of steelnow i heard a few times that batman was in iti didn't se him.in the film is it something subtle I've just missed or is he not in it?when i googled it got loads of results for them being together in the new film but nothing about man of steel 2013

- No Batman will be in the next superman film think it's scheduled for next year

- Q: How are steel coils processed and shaped into different products?

- Steel coils are processed and shaped into different products through a series of manufacturing processes. The first step in the process is called uncoiling, which involves unwinding the steel coil and straightening it. This is usually done by feeding the coil through a machine called a decoiler. Once the coil is uncoiled, it goes through a process called leveling. This is done to eliminate any unevenness or warping in the steel. The coil is passed through a set of rollers that apply pressure and flatten the steel to the desired thickness. This ensures that the steel is uniform and ready for further processing. After leveling, the steel is typically cut into smaller pieces or sheets. This is done using machines such as shears or slitters, which can cut the steel into different widths or lengths. The precise dimensions will depend on the requirements of the specific product being manufactured. Once the steel is cut, it can undergo additional shaping processes. One common method is called roll forming, where the steel is passed through a series of rollers that gradually shape it into the desired profile. This is often used to produce products such as roofing sheets, wall panels, or beams. Another common shaping process is called stamping. In stamping, the steel is pressed between a die and a punch to create complex shapes or patterns. This is commonly used in the automotive industry to produce components such as car body panels or engine parts. In addition to shaping, the steel may also undergo surface treatments or coatings to enhance its properties or improve its appearance. This can include processes such as galvanizing, where a layer of zinc is applied to protect the steel from corrosion, or painting to provide a decorative finish. Overall, the process of shaping steel coils into different products involves a combination of cutting, shaping, and surface treatments. These processes are carefully executed to ensure that the steel meets the required specifications and is ready for use in various industries.

- Q: I saw this really pretty ring online and it was made of steel. Is this a good ring? If I were to wash my hands with it on, would it rust and turn my finger green?

- Steel rust is brown not green! Very much expected to be of one type of stainless steel, and you should have no problem.

- Q: Why do we galvanise steel? Galvanised steel is steel coated with zinc.

- The coating of zinc inhibits rust. First of all the zinc does not oxidize a readily as iron (steel). If the zinc coating gets scratched it still protects the exposed iron. When the zinc and exposed iron get wet they behave like a battery. Electrons flow from the zinc layer to the iron layer. The extra electrons in the iron layer replace any that might be lost to oxidation and help keep the iron metallic. Of course now the zinc oxidizes faster so eventually all of the metallic zinc is removed and the iron is unprotected and will rust. The fact that the zinc doesn't have to cover the steel is shown in another process. To protect the steel hulls of ocean going ships a block of zinc is attached to the bottom. The electrical circuit behaves as described above. When the zinc block has dissolved they just attach another one. If they keep this up the hull of the ship remains corrosion free. A tin coating on steel (as in a tin can) works just the opposite. When the tin is scratched the electrons flow from iron to tin so the iron rusts faster than it would have with no tin.

- Q: How long does the coating on steel coils last?

- The longevity of the coating on steel coils depends on various factors such as the type of coating used, the environmental conditions it is exposed to, and the maintenance practices. However, on average, a well-applied coating can last anywhere from 10 to 20 years before requiring reapplication or maintenance.

- Q: Are they made using the same processes, or is tempered steel made without the quenching process?

- Hardening is the preliminary process. The fully hardened state may be far too brittle for practical use. The tempering process is tailored to reduce the actual hardness, to introduce more flexible alloys. The tempering method employed may be done at relatively low temperatures, but some alloys require prolonged soaking at elevated temperatures. Some may be cooled in air, but others may require quenching to end the process.

- Q: My mother is in a weilding class, and today she accidentally welded Galvanized Steel. She doesn't feel good and she wants to know what the symptoms are for Galvanized Poisoning from breathing in the Fumes. Please help, I am worried for her.

- Galvanized steel is nothing more than regular steel with zinc added. However, unless you wear the proper gear or ventilate the fumes away, the zinc can cause heavy metal poisoning. As someone who has suffered from it before, usually the symptoms are an upset stomach, feeling queasy, diarrhea, and sometimes hallucinations. If it is bad, you start getting joint pain, a metallic taste in your mouth, and develop a fever. Usually, you can treat mild zinc poisoning by drinking lots of fluids and flushing out your system as much as possible. Still, if the problems persist for more than an hour or so, it can be lethal with many blacksmiths having died as a result of it. If she still feels bad, call a poison control center and tell them she breathed in zinc fumes. They will probably tell you to go to the ER to start treatment. It is not something you wait out.

Send your message to us

Galvanized Steel Sheet in Ciols with Prime Quality Best Seller

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords