Galvanized Steel Coil Best Quality Green Color

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Pre-Painted Galvanized/Aluzinc Steel Coil Description:

With GI as base material, after pretreatment (degrease and chemical treatment ) and liquid dope with several layers of color, then after firing and cooling, finally the plate steel is called pre-painted galvanized (aluzinc) steel. Pre-painted galvanized steel is good capable of decoration, molding, corrosion resistance. It generally displays superior workability, durability and weather resistance.

2.Main Features of the Pre-Painted Galvanized/Aluzinc Steel Coil:

• Excellent process capability

• Smooth and flat surface

• Workability, durability

• Excellent heat resistance performance

• High strength

• Good formability

• Good visual effect

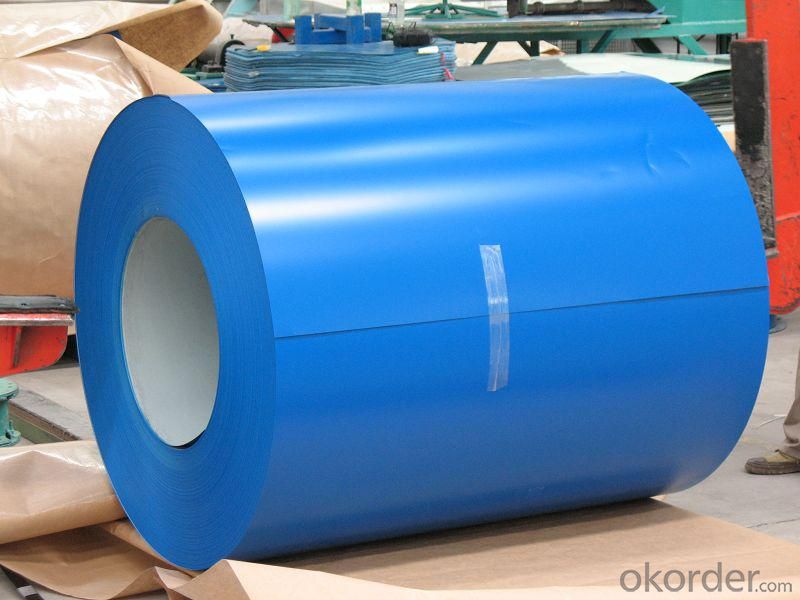

3.Pre-Painted Galvanized/Aluzinc Steel Coil Images:

4.Pre-Painted Galvanized/Aluzinc Steel Coil Specification

Standard: AISI, ASTM, BS, DIN, GB, JIS

Grade: DX51D, DX52D

Thickness: 0.17-2.0mm

Brand Name: KMRLON

Model Number: coil

Type: Steel Coil

Technique: Cold Rolled

Surface Treatment: Coated

Application: Boiler Plate

Special Use: High-strength Steel Plate

Width: 20-1250mm

Length: customized

commoidty: pre-painted galvanized steel coil

Thickness: 0.13-4.0mm

width: 20-1250mm

zinc coating: 40-180g/m2

printing thickness: top side: 20+/-5 microns, back side: 5-7 microns

color: all RAL color

surface treatment: color coated

coil weight: 4-7 tons

coil ID: 508/610mm

packaging: standard seaworthy packing

5.FAQ of Pre-Painted Galvanized/Aluzinc Steel Coil

Roof, roof structure, surface sheet of balcony, frame of window, etc.

We use the best brand of all of the word—AKZO.

3. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

4. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

- Q: I was cutting a sheet of steel with an angle grinder when suddenly the rate at which the blade was cutting slowed way down. I tried a few different things, and turned off the tool and looked at the blade. It didn't look damaged, but it definitely was not cutting as quickly. I thought either I had hit a harder section of steel (is that possible? It looked pretty uniform) or the blade had lost it's abrasive quality or something. Also, before this happened I had accidentally cut into the wooden sawhorse that was holding up the steel sheet, but I've done that before with no problem. After a short while the problem fixed itself and the rate of cutting went back to a fast normal. Anyone know why this happened?

- Sounds like the abrasive surface got blinded, coated with something that prevented the abrasive particles from touching the steel. It is possible to have vastly different hardnesses in a single piece of steel. Case hardening, carburizing, induction hardening, heat affected zone from welding, differences in work hardening, and presence of inclusions are some of the things that can create hardness variation within a single piece. But... sounds like you are working with a sheet which is unlikely to have any of these conditions. So... it was probably the grinding disk

- Q: Can steel coils be coated with self-cleaning materials?

- Yes, steel coils can be coated with self-cleaning materials.

- Q: How do steel coils contribute to structural integrity in buildings?

- Steel coils contribute to structural integrity in buildings through their strength and durability. By using steel coils in the construction of beams, columns, and other load-bearing components, buildings can withstand heavy loads, resist deformation, and maintain their stability over time. The high tensile strength of steel coils allows for the creation of lightweight yet sturdy structures, ensuring the overall safety and longevity of the building. Additionally, steel coils offer excellent resistance to corrosion, fire, and extreme weather conditions, further enhancing the structural integrity of buildings.

- Q: What is the minimum temperature that steel coils can withstand?

- The minimum temperature that steel coils can typically withstand without undergoing significant changes in their physical properties is around -40 degrees Celsius (-40 degrees Fahrenheit). However, this can vary depending on the specific type and grade of steel used in the coils.

- Q: If you were selecting a tool steel for an extreme impact load application, which one would you pick? why?thanks

- It all depends what the application actually is. For hammers I would select a hammer grade B1 steel. For impact loading where an edge is needed I would be going for O1 or similar (oil quenching steels tend to be a little tougher than air hardening). For mining tools a very high manganese steel (Hadfields steel) - this is not a true tool steel. The best place to start is by looking at the ranking of the properties which you want - hardness v toughness v strength - and then use this to put the steels in rank order. Price and availablity then sort the problem out for you (in the real world).

- Q: what do you think about producebility of low density steel? for example: can density of 1020 steel (or ony others) be decreased without any loss of other properties.

- If a material has a lower density than steel, then it isn't steel.

- Q: What are the different types of steel coil finishing tools?

- There are several different types of steel coil finishing tools used in the metalworking industry. These tools are designed to add various finishes to steel coils, enhancing their appearance and functionality. Some of the common types of steel coil finishing tools include: 1. Slitting Machines: These tools are used to cut large steel coils into narrower strips. Slitting machines have sharp circular blades that can efficiently slice through the coil, resulting in multiple smaller coils of desired widths. 2. Levellers: Levellers are used to flatten and straighten steel coils. They apply pressure to the coil, ensuring that it is perfectly flat and even. Levellers are particularly useful when the steel coils have undergone deformation during the manufacturing process. 3. Recoilers: Recoilers are used to rewind steel coils into a tighter and more compact shape. These tools are typically used after slitting or levelling to create coils of a specific diameter or size. 4. Edge Trimmers: Edge trimmers are used to remove any excess or uneven edges from the steel coils. They can remove burrs, rough edges, or any other imperfections, resulting in a clean and smooth finish. 5. Inspection Machines: Inspection machines are used to examine the quality of the steel coils. These tools can detect any defects, such as surface imperfections, scratches, or dents, ensuring that only high-quality coils are delivered to customers. 6. Coating Machines: Coating machines are used to apply protective coatings to steel coils. These coatings can be in the form of paint, zinc, or other materials, preventing corrosion and enhancing the durability of the coils. 7. Packaging Machines: Packaging machines are used to wrap the steel coils securely and protect them during transportation and storage. These machines can apply plastic or metal straps, shrink wrap, or other packaging materials to ensure the coils remain intact and undamaged. Overall, these different types of steel coil finishing tools play a vital role in the metalworking industry, allowing manufacturers to produce high-quality and visually appealing steel coils that meet the specific requirements of their customers.

- Q: I just want to know why is cold steel katana a very good sword?? How can you tell if a cold steel katana is good or not

- Save your money and by a wooden boken. Train with a well balanced wooden one. It is how the great Japanese master started their training. Steel swords are good for display. and perhaps if you become relay good and want to feel the heft and practice cutting straw men and bamboo stalks than invest some money in the real deal for a few hundred $$ at the least.

- Q: What are the main factors that affect the surface quality of steel coils?

- The main factors that affect the surface quality of steel coils include the quality of raw materials used, the manufacturing process employed, the level of cleanliness and maintenance of equipment, the presence of contaminants or impurities, the coating or finishing applied, and the handling and storage conditions.

- Q: What is the shelf life of steel coils?

- The shelf life of steel coils is indefinite if they are stored properly. Steel coils are known for their durability and long-lasting nature, making them suitable for extended storage periods without any degradation in quality. However, it is important to store them in a dry and well-ventilated area, away from moisture and corrosive substances to prevent any potential damage.

Send your message to us

Galvanized Steel Coil Best Quality Green Color

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords