Galvanized Rolled Steel Coils/Sheet from China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 500000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description of Prepainted Galvanized Steel:

1.material : galvanized steel sheet / prepainted galvanized sheet

2.sheet thickness : normal use 0.3-0.6mm

3.length: any length, according to the transportation, generally less than 12m

4.color: standard color: red, blue, white, grey; special color: according to RAL color

Specification of Prepainted Galvanized Steel:

Thickness:0.15mm-1.2mm

Width:600mm-1250mm

Coil ID:508mm/610mm

Base Metal: GI/GL.

Zinc Coating:30-275 G/M2

Paint Coating: Top 30; Back 5-7. Or up to Buyer’s Option.

With Protection Film or Without Protection Film.

Spangle: Regular Spangle, Small Spangle, Zero Spangle.

Coil Weight:3-5MT or Customized Weight.

Delivery:15-25 days

MOQ:25MT

Color: RAL Color Series or Customized Colors.

Temper: Commercial Quality G 350; Structural Quality: G550; Full Hard.

Charactics of Prepainted Galvanized Steel

It can be widely used in transportation, light industry, civil usage and farming. It is also the perfect building material in construction for making steel roofing, insulation panel, corrugate sheet, facade wall, shutters, T-bar and home appliance.

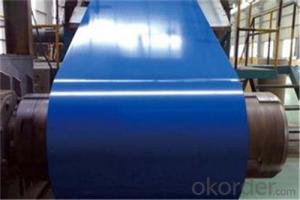

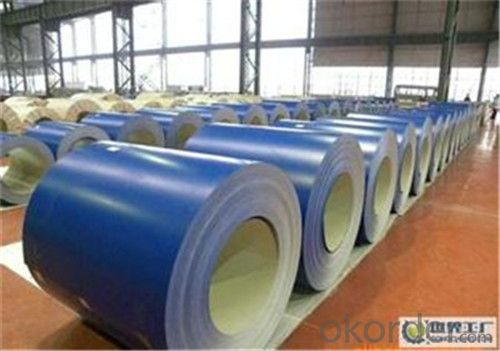

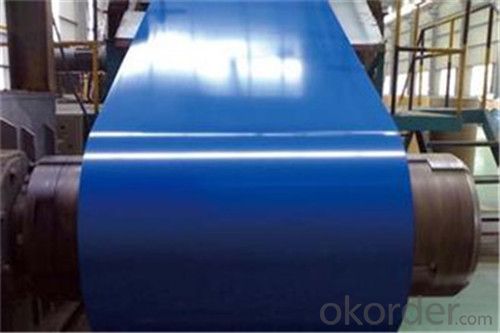

Images of Prepainted Galvanized Steel:

FAQ

1.What's your MOQ?

25MT, it is for one container.

2.Do you have QC teams?

Yeah, sure, our QC team is very important, they will keep the quality control for our products.

- Q: What is the yield strength of steel coils?

- The yield strength of steel coils can vary depending on the specific type and grade of steel being used. However, in general, the yield strength of steel coils typically ranges from 30,000 to 100,000 pounds per square inch (psi).

- Q: I am thinking about getting a cold steel tilite or a kershaw leek or possibly a buck sirus. If you have had any experience with these knives please give it to me. thanks

- Kershaw Steel

- Q: I found this amazing kid on youtube - is he using nylon or steel strings?(I'm buying my first guitar! helpp)oh and is fingerstyle also possible in steel string guitar? does it hurt?(I might sound really stupid-..)thanks a lot

- Lol that's sung ha jung. You can play with both types but it is easier to start off learning in nylon.

- Q: How are steel coils used in the aerospace industry?

- Steel coils are used in the aerospace industry for various applications such as structural components, engine parts, and aircraft frame construction. These coils are often used in the manufacturing process to fabricate strong and durable components that can withstand the extreme conditions of flight.

- Q: For some reason, if you rub iron oxide or lodestone (both very crumbly, dark, mineral-like materials) into soft, unhardened steel, their particles actually get stuck into the surface of the steel (that is, darkening it). My question is, how does this work? How come iron oxide and lodestone can get stuck, and how come other materials (like silicone carbide, for example) do not?My second question is, are there any materials that can get stuck into steel, that is also blue in color, and how would I best obtain it?

- If you look at the surface of untreated steel even with a low power microscope you will see a surface that is far from smooth, there are pits and occlusions dotting the surface. Steel is not polished when you see it this way so the only treatment to the surface was the extrusion process or forming done on it by the presses. Iron oxide has a very small particle size and when pulverized into a powder it can easily fill the pits and voids in the steel surface coloring it.

- Q: How are steel coils used in the production of agricultural structures?

- Steel coils are used in the production of agricultural structures as they are the primary material for manufacturing various components like beams, columns, and trusses. These coils are typically shaped, cut, and welded to form the framework for buildings, barns, silos, and other agricultural structures. The strength and durability of steel make it an ideal choice, ensuring that the structures can withstand harsh weather conditions and support heavy loads, making them essential for the agricultural industry.

- Q: How are galvanized steel coils different from regular steel coils?

- In terms of their protective coating, there is a difference between galvanized steel coils and regular steel coils. Galvanized steel coils have a layer of zinc coating, which serves as a barrier against corrosion and rust. This process, called galvanization, involves immersing the steel coils in a bath of molten zinc or applying zinc to the surface using different methods. On the other hand, regular steel coils lack this protective coating, making them more prone to corrosion and rust. The zinc layer on galvanized steel coils not only functions as a physical barrier but also provides sacrificial protection. This means that if the coating is scratched or damaged, the zinc sacrifices itself to shield the underlying steel from corrosion. Consequently, galvanized steel coils are highly durable and suitable for applications that require resistance to harsh environmental conditions. These applications include outdoor construction projects, automotive manufacturing, and the production of household appliances.

- Q: How are steel coils uncoiled?

- Steel coils are typically uncoiled using a machine called a decoiler or uncoiler, which gradually unwinds the coil by feeding it through a set of rollers. The rollers apply tension to the coil, allowing it to unwind smoothly and evenly. The speed and direction of the uncoiling process can be controlled to match the specific requirements of the application.

- Q: How are steel coils used in the manufacturing of elevator components?

- Steel coils are used in the manufacturing of elevator components as they provide the necessary strength and durability required for various parts such as brackets, frames, and shafts. The coils are shaped, cut, and welded to create the desired elevator components, ensuring a sturdy and reliable structure that can withstand heavy loads and constant usage.

- Q: How are steel coils used in the production of industrial shelving?

- Steel coils are used in the production of industrial shelving by being processed and shaped into various components such as shelves, frames, and brackets. These coils are cut, bent, and welded to create sturdy and durable structures that can support heavy loads in industrial settings. The strength and versatility of steel make it an ideal material for manufacturing industrial shelving, ensuring durability and longevity of the shelves.

Send your message to us

Galvanized Rolled Steel Coils/Sheet from China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 500000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords