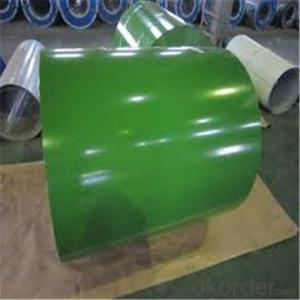

Galvanized Rolled Steel/Aluzinc Rolled Steel

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 12000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

JIS g3141 spcc cold rolled steel coil

Grade :SPCC,SPCD,SPCE

Width:600-1500mm

WT:0.15-3mm

Product Feature

Packaging Details: Wrapped by water prove paper and plastic film, covered by steel sheet, strapped with steel strips to prevent damage from transportation

Product Specification / Models

Standard: AISI, ASTM, DIN, GB, JIS

Grade: Q195, SPCC, SPCD, SPCE, DC01-0S, St12, ST14, ST15, ST16

Thickness: 0.2mm-2.0mm

Place of Origin:China (Mainland)

Model Number: 0.2-2.0mm*600-1500mm

Type: Steel Coil

Technique: Cold Rolled

Surface Treatment: oiled

Application: Construction,mechine,building,container manufacture,shipping building,

Special Use: High-strength Steel Plate

Width: 1000mm,1200mm,1219mm,1250mm,1500mm or as per customer's request

Length: Coil or as customs' request

Carbon constructional steel: SPCC,St12,DC01,Q235A/B/C/D Constructional quality steel: 20-45#,08-15#

Carbon quality steel coil: 08AL,Z,S,P SPCD,ST14

Low carbon deep-drawing coil: SC1,SPCE,SPCEN,ST14,DCO4 Extra-deep drawing coil: SC2,ST15,DCO5,SC3,ST16,DCO6,ST17 Corrosion-resistant steel: 05CuPCrNi,09CuPCrNi,Q345GNHL

Low carbon drawing steel: SPCD,ST13,DC03

Steel Coil: COLD ROLLED

Certificate: ISO, SGS, BV

Application

1.common structural parts and parts for drawing in engineering machines

2. transportation machine construction machines, lifting machine,

3. agricultural machines, light and civil industrial, household appliance industries.

4. chemical equipments, drive casing pipe and light industrial civil industries.

Other Information

Name Cold Rolled Steel Sheet Coil

GB11253-89,Q195 Q235,IS G3141,SPCC SGCC SPCD SPCE,DIN1623,ST12 ST13 SPCD ST14, EN10130,DC01 DC02,DC03

Thickness 0.18-3.0mm

Width 680mm-2000mm or 1000/1200/1219mm/1250mm

Finish General, bright, dull and mirror finish, oiled or non-oiled

Coil ID 508mm

Coil weight 5-12 tons.

Packing as client's requirement

Certificate ISO9001:2008

Standard GB11253-89, JIS G3141,DIN1623,EN10130

- Q: Are steel pokemon weak against any attacks? If so, what types? (like water, grass, etc.)

- I believe a fire pokemon wins against a steel.

- Q: Ok, I need two negative facts about steel wheels and two for aluminum wheels. im designing a wheel for a project in design and draw for production class. Also if you find a web site that you got the info from plz refrence it i need to write down the source of the info, but if you can't its ok. Thanks

- Negative facts for steel wheels: (1) Not as many style choices as aluminum. (2) Rust easily even when painted or powder coated, due to rock chips. (3) Heaver than aluminum, as far as fuel economy. Negative facts for aluminum wheels: (1) More sensitive to proper torquing of lug nuts. IE torque must be checked more often. (2) Susceptible to impact damage from road hazards much more than steel. (3) Need constant attention to prevent oxidation. Are these what you are looking for? I hope so. Wingman

- Q: How are steel coils used in the automotive industry?

- Steel coils are widely used in the automotive industry for various applications such as body panels, structural components, and engine parts. They are typically formed and shaped into desired forms through processes like stamping, bending, and welding. Steel coils provide strength, durability, and corrosion resistance to the vehicles, ensuring their safety and longevity.

- Q: We bought a new fridge and the magnets don't stick to the front where the stainless steel is.

- The stainless steel which dont exhibit magnetic properties are austenitic grades of steel.

- Q: I want to hear from those who own a scandium revolver. I know that scandium makes for a much lighter gun than steel, but how do they hold up durability-wise? Is their lifespan shorter than a comparable steel revolver?

- Yes, they are as durable as steel and lighter than aluminum, but they amplify the recoil when firing due to its light weight.

- Q: How much should someone sell a 6 ft stainless steel counter? How about one with a sink?

- Sheet stainless steel is about $2.00 to $2.75 per lb. in the US right now for a 2B stainless steel without any special finish. The cost of a sink or counter is going to vary widely. The labor to fabricate it is going to be a lot higher than the material cost so the price per pound is not going to tell you much. In California a custom 6' counter would be somewhere between $1,200 and $3,000. A standard size single compartment sink would be about half of that.

- Q: What are the different types of steel coil grades?

- There are several different types of steel coil grades used in various industries and applications. Some of the most common steel coil grades include: 1. Carbon Steel: This is a basic type of steel that contains mostly iron and carbon. It is widely used in construction, automotive, and manufacturing industries due to its high strength and durability. 2. Stainless Steel: This type of steel contains chromium, which provides corrosion resistance and makes it suitable for applications that require resistance to oxidation and staining. It is commonly used in the food processing, chemical, and medical industries. 3. High-Strength Low-Alloy (HSLA) Steel: HSLA steel contains small amounts of alloying elements such as copper, phosphorus, niobium, and vanadium. This type of steel offers higher strength and better mechanical properties compared to carbon steel, making it suitable for structural applications. 4. Galvanized Steel: Galvanized steel is coated with a layer of zinc to protect it from corrosion. It is commonly used in outdoor applications, such as roofing, fencing, and automotive parts. 5. Electrical Steel: Also known as silicon steel, electrical steel has high magnetic permeability, low electrical conductivity, and low core loss. It is used in the production of transformers, motors, and other electrical equipment. 6. Tool Steel: Tool steel is a high-carbon steel that is specifically designed for making tools and dies. It has excellent hardness, wear resistance, and toughness, making it suitable for cutting, forming, and shaping materials. These are just a few examples of the different types of steel coil grades available. Each grade has its own unique properties and characteristics, making it suitable for specific applications in various industries.

- Q: Heard some steel companies like TATA Steel and JSW are in good performance. can some one suggest me if its good time to invest in steel industry ?

- I feel metal stocks can give some return now if you invest.

- Q: I've played guitar for years, now I want a steel guitar. As a beginner, to learn and experiment with, which one would be better for me?

- Pedal steel is very difficult. You need to co-ordinate both hands, both feet and both knees to play it effectively. Lap steel is a lot easier. I suppose it depends how much of a challenge you want. A good lap steel guitar is usually cheaper than a good pedal steel too, so that's another consideration to take into account.

- Q: I downloaded broken steel, the notice of my level cap raising was shown, but after reaching the Jefferson Memorial (when you are supposed to activate the purifier) if I kill Colonel Autumn, then Lyons simply says that we must secure the area, and I can't complete the mission. If I let Autumn live, then she gets stuck in a loop saying Steel be with you over and over. Has anyone else experienced this/how can I fix this? I paid $10 for the expansion and I'm getting ripped off.

- for my area i've got in no way stricken with achievements. Hell, i've got in no way logged into domicile windows stay in six months for the reason that this game got here out. i do no longer even have the disk in my laptop. I merely launch by FOMM and FOSE. you already know what achievements i like, making mods. human beings love a number of my mods, and to me this is a real success. the sport is merely game, enjoying it would not recommend something, this is different from you lived in SE Asia for 6 months in a shack with out working water with a warm distant places female you met on line and then introduced her and your toddler back to stay inclusive of your mom, no, you haven't any longer achieved something different than to be entertained by skill of somebody else's success. Oh, specific you have solved some mysteries, explored some areas and located some issues that have been hidden, yet you likely regarded up on line the places for lots of the stuff you discovered besides. Oh, and to respond to your question: Bethesda's engaged on it, alongside with fixing the a million.5 replace that kills mods with outdoors adjustments by skill of making the sport crash on shop.

Send your message to us

Galvanized Rolled Steel/Aluzinc Rolled Steel

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 12000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords