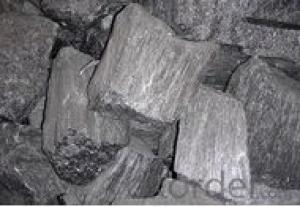

Raw Materials for Refractory:Fused Mullite M70 with Competitive Price from Henan

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC or DP

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

· Place of Origin: Henan, China

· Shape:particle or powder

· Material:SIC

· Al2O3 Content (%): 70-77%

· Fe2O3Content (%): 0.1max

· SIO2 Content (%): 22-29%

· CAO+MGO Content (%): 0.3max

· BD (G/CM3): 2.9min

· Model Number:Customer's Requirement

· Brand Name:CMAX

· Application:Metallurgy or Refractory

· Product name:Fused mullite

· Color:WHITE

· Size:100MESH/200MESH/0-1MM/1-3MM/3-5MM/0-40MM or as customer's request

· Certificate:ISO9001

· Usage:Refractory

· Type:Refractory raw materials

· shape:particle or powder or clinker

· Packaging Details:Bags/In bulk/As costomer's requirement'

- Q: What do RH and DH stand for in refractories?

- DH :For human intelligence (diameter, board of directors). )

- Q: What is the main constituent of refractory brick?

- Primarily magnesium oxide and sodium silicate as binder.

- Q: What's the fireproof specification for constrcution external wall thermal insulation materials?

- incombustible material: Class A1 (homogenous): such as YT inorganic active insulation material for wall thermal, foam glass, rock(ORE) wool, glass wool, insulation?board of aerogel,expanded perlite series, expaned glazed hollow bead, foam insulation boards, ETC. Class A2 (non-homogeneous composite): such as phenolic foam, gelatine powder polyphenyl granule thermal insulation material, inorganic coating materials and other nonflammable material. phenolic foam insulation board, urea resin foam and board, high flame-retardant polyurethane rigid foam and board, high flame retardant polystyrene cystosepiment, gelatine powder polyphenyl granule heat insulating slurry and other combustible?materials. Requirements for combustion levels of common antiflaming EPS, common inflaming retarding XPS, common antiflaming rigid PU foam board: Class A is incombustible?material (product); B1 nonflammable material (product); B2 combustible?material (product); B3 combustible material (product).

- Q: What's the organzational structure of refractory material?

- Ingredients (harmful); phase composition. The main components of refractory material include chemical composition and phase composition. The addtional components include main crystal phase, matrix, crystal phase, chemical composition

- Q: Is the linear change on reheating the same as heating permanent linear change of refractory material?

- “+”represents expansion. the afterexpansion and aftercontraction after cooled to be at room temperature. The change may significantly damage the masonry of thermal kiln. There are regulations on the linear change on reheating of common refractory material in the national standard. Some physical chemical changes may continue. It is defined as the change from being heated to the specified temperature of refractory material sample. Heat preserving for a while till afte cooling to be at room temperature, then the residual will expand or contract in its length, heat preservation for a while, organization vitrification, the irreversible changes of its length refers to heating the firing refractory to be at high temperature, so as to make the volume of refractory materials expand or contract, due to the influence of uneven temperature or lack of time, otherwise it will cause the deformation of the refractory ball and make this indicator within standard even reach smaller value, so firing control must be strengthened in product production. But it is should not be too high. For refractory materials with same chemical composition, the linear change on reheating is produced in the heating process. Properly increasing sintering temperature and prolonging the holding time is an effective process measures, make its firing inadequate. When subjected to high temperature, it can reduce the thermal shock resistance. Minus sign "-" represents contraction. The permanent line rate refers to heating the fire refractory ball to the specified temperature. Linear change on reheating, also known as residual linear change, is an important indicator to assess the quality of refractory in the long time use. To control the permanent line rate within the standard or reach the minimum value.

- Q: Who knows how many kinds of fireproof insulation materials are there in the market?

- The so-called A-level materials in fire insulation materials, namely, the WW non-combustible insulation materials, and the WW material s are A-level. Inorganic fireproof and thermal insulation materials can be used as wall insulation materials to replace red bricks, therefore, they, as thermal and cold insulation materials, can reduce the thickness of walls, and save energy, as well as expand applicable areas indirectly, decreased structure weight. They are very good.

- Q: What is the quote of fireproof and soundproof materials used in KTV?

- acoustic material, aluminum foil glass wool, sound-deadening material, glass wool, cinema / KTV dedicated glass wool: The classification of glass fiber products: The category of glass wool felts: The level of insulation cotton: A-level brands: New applications: The origin of GB/T13350-2008: The coefficient of thermal conductivity(room temperature): 0.035 bending at low temperature≤: 0.02 elongation at break: ≤80kPa flexure strength: ≤120kpa Compressive strength: ≤150kpa application temperature: 700 Core material: The shape of glass wool: Fibrous shape: Coil Specifications: Complete quote is 23 Yuan per cubic meter. glass wool board, KTV sound insulation core material: The shape of glass wool: The level of rectangular glass wool: A-level non-combustible brands: Kunnai material: The origin of glass fiber: Guangzhou, Shijiazhuang, Wuhan, the quote there is 8.8 Yuan per cubic meter.

- Q: How is the development of Xinmi refractories industry? What's its advantages and disadvantages?

- The advantages are largest scale, top production amout in the country, accounting for one-third of the national market, having technology, strength and the market. The disadvantages are the lack of mineral resources, serious environmental pollution,

- Q: What is the biggest difference between refractory bricks and clay refractory bricks? Where can I find information on the refractory bricks?

- You can look up knowledge manual of refractory material to find phosphatic material, etc. Xinjiang refractory bricks, castable refractory, refractory material, silicious, corundum and alumina-magnesia: High alumina and clay refractory bricks can be divided into

- Q: What is refractory?

- Refractory materials are widely used in metallurgy, machinery manufacturing, chemical industry, petroleum, power and other industrial fields. It is an inorganic nonmetallic material mostly used in metallurgical industry with the minimum refractoriness of 1580 ℃, able to resist high temperature without softening (annealing). It accounts for 50% to 60% in total output. Refractoriness refers to refractory's ability to resist fire.

Send your message to us

Raw Materials for Refractory:Fused Mullite M70 with Competitive Price from Henan

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC or DP

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords