FSK Roofing Insulation Adhesive Heat Insulation Materials

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Description:

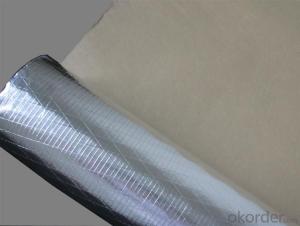

FSK7180 is the most popular laminated thermal insulation sheeting for covering ducts and pipes wrapped up by a thermal insulator such as glass wool and rock wool, PU foam and other insulation to protect them against vapor moisture in order to work more effectively, includes an reflective aluminum sheet and a fiberglass network disposed on and over a surface of the aluminum sheet

2. Construction & Benefits:

Reflective Aluminum Foil Lined With Kraft and Reinforced by fiberglass from 3 directions make this products durable. This Kind of FSK have more fiberglass as Scrim. So that thisFSK 7180 have more strength than FSK 7160

Aluminum foil which is a good barrier to moisture, rust and the air, and friendly to environment, good conductivity from the aluminum layer eliminates the electrostatic effect easily as exposure and kraft being liner to rise the strength, they sandwiched together through polyethylene as adhesive.

l High performance cost ratio: reasonable price and professional service.

l Environment friendly: it does not contain any hazardous or harmful materials.

l Convenient to use, easy to be folded into various shapes according to actual needs.

l Better resistance and tenacity according to glass fiber within.

l Reduces heat loss in winter, heat gain in summer.

l Not effected by moisture and humidity.

l No special handling or breathing protection required.

3. Application:

It could be used as reflection, packing paper, moisture proof, radiant barrier and easy to fold as your need.

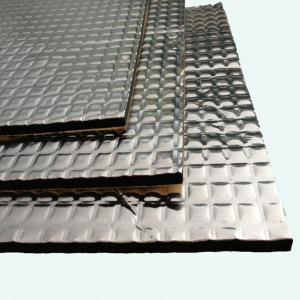

1. As a heat insulation materials in car, train, roof and wall, also been attached to glass wool blanket, rock wool board, mineral wool for get better performance.

2. A laminated thermal insulation sheeting. for covering ducts and pipes wrapped up by a thermal insulator such as glass wool and rock wool, PU foam and other insulation to protect them against vapor moisture in order to work more effectively.

3. As a sound absorber in KTV room, cinema, opera house, factory and other building.(only indicates 7160P, 7150P)

4. Package of industrial products and other place that you want to use.

4. Dimension/Size

(1) Roll width: 1000mm, 1200mm and 1250mm

(2) Roll Length: 50m, 100m, 200m, 500m, 1000m, or upon request.

(3) Core I. D.: 3"(76mm+/-1)

5. Similar products & guide

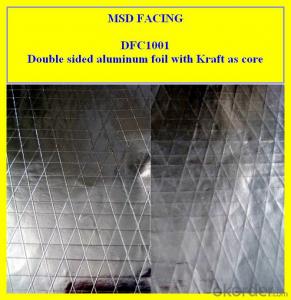

(1) DFC1001: Double sided aluminum foil supply better perfomance and function.

(2) FSK7160-P, perforate the FSK7160 as to absorb acoustic

- Q: Our roof tile is installed on top of galvanized iron sheets. We do not have any toher form of insulation. The roof tile or tegula is quite thick.

- Absolutely. You will find in the summer that your tiles will heat up from the sun and will stay hot even after dark (the steel sheets don't exactly help either). Your energy bills will go down about 60% in the summer and 20% in the winter by just installing a cheap fiberglass filling. A good example of how these tiles are effecting you house would be a stoneware cup. Pour hot water into it and place it in the microwave until it boils. Feel that the side are very hot, too hot to hold (this represents the sun heating up the tiles). Now pour out that cup and fill it with cold water (which would represent AC in your home). In about 2 or three minutes, place your finger in the stoneware cup. The water will be warm. The tiles do the same thing. The absorb and distribute heat into your home during the warm months, and will rob your home of it's heat during the winter and cool months. Just by placing insulation in your home, you stop that unwanted heat exchange with your home and the outside world.

- Q: I have an apartment building that has mold in it. I'm trying to do everything I can to increase the airflow. Sure, the tenants might have to spend a mint on heat, but if it improved the air quality, maybe it would be a good idea.

- You can remove it, but why not replace it with rolled insulation? I'm sure you're local State Board of Health would disaprove of not having your tenant's homes properly insulated. You could get into a lot of legal trouble if you do not keep you apartment building properly maintained.

- Q: I do not have extra space on the roof. Roof also tapers to drains at one end of building.

- the R values, i am not sure. that white stuff is NOT Styrofoam. it is a cheap imitation. Real Styrofoam is made by DuPont, is usually a light blue, with a plastic seal coat on both sides. that thin plastic seal coat doubles the R value. what really does the insulation, is trapped air. air is actually a poor conductor of heat. the foam is actually little bubbles of air. dead air that is, air that cannot circulate and move. it works similarly to the way a down vest or coat works, it fluffs up and holds the air pockets out within a confining structure, thus retaining heat. the rigid stuff will last much longer, i can tell you that much. the white foam stuff deteriorates quickly. buy cheap, get cheap, is the general rule. you may wind up only having to do it again in a few years.

- Q: My new room is an addition to a mobile home, and has a single-layer metal roof. I have 3 "main" concerns. What are the cheapest and/or most effective ways of eliminating them?1. No heat insulation- cold air sinks from the roof to my room, and my warm air rises to the roof and cools.2. Condensation forms on the inside and drips occasionally. My computer, bike, and downhill boards are in here!3. It seems like bugs could easily get into my room, but that's just a suspicion.

- You really need a correct "building paper" under the iron. It is aluminum with a tar sandwiched between...You can also use plastic sheeting as a vapor barrier..

- Q: if you had snow and all the snow is off your roof and the house nex store has snow do we need insulation?

- You hit the nail on the head and is a direct indication that you need more insulation. As a matter of fact, many carpentry companies send the sales force out in the winter (When new home building is slower) to look for houses with no to little snow on their roofs compared to their neighbors. This is an indication that the roof is allowing to much heat to escape which then melts the snow on the roof. But take one other thing into account. Was the wind blowing? If the wind is blowing, it could blow snow off your roof and not your neighbor due to his location, obstructions(such as tree's, other buildings) or design of his roof. lastly, depending on the orientation of your home, more sunlight can hit your roof than your neighbors allowing more snow to melt. If your roof is darker compared to your neighbor, it can increase your snow melt compared to your neighbor. If the snow is recent and your neighbor has snow on the roof and you don't, chances are that you need insulation as $$$ is escaping out of your ceiling.

- Q: im thinking of putting rolled felt paper under my metal roofing would that work instead of the reflective insulation instead?

- I installed a metal roof 5 years ago. I stripped the roof down to the plywood and put down 30# felt. This was what the manufacturer recommended. The felt is not for insulation though. The company was Metal Sales out of PA. They are glad to give advise.

- Q: a roof that is built with the insulation covering the waterproof membrain is ?

- Not done properly.

- Q: Can you put fiberglass insulation on the under side of roof tiles in the loft in the house?

- You should not be able to see your roof tiles from inside your house. So no, it can not be done. You can attach insulation to the rafters if that is what you meant.

- Q: I already have fiberglass in the attic, but would like to add more.

- Your best angle is to go with blow in fiberglass. ownes corning and Johns mansville both make good blow in fiberglass. Menards and Home depot in our area will lend you a blow in machine for free but make sure you have 2 people to run it and that you have a TIGHT sealed face mask for the guy in the attic along with safety goggles. No way around it either that guy in the attic is gonna get itchy, so expect that now. I put blow in cellulose over my attic fiberglass bats to bring it up to R-50 but i regret it now. I should have stuck with fiberglass. I did some research after the fact and there is some flammability issues with the cellulose i used and on top of that it is seriously dusty so i cant store anything in the attic space anymore. Cellulose was cheaper and the "green" choice but if i could reverse time I would have gone fiberglass blow in.

- Q: If I insulate my roof, should I put in those plastic vents that go between the studs for air flow? I would like to use it for a work shop and probibly have some kind of heat source. i live in Northern Alberta.....

- Insulate the ceiling, not the roof. Place the vapor barrier (foil or heavy paper) facing the garage. For Alberta you want at least R-30, or 9" of fiberglass insulation. The garage should already have eave vents, hold the insulation away about a foot from them so the insulation does not block the air flow from them.

Send your message to us

FSK Roofing Insulation Adhesive Heat Insulation Materials

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords