FRP Pultrusion Profiles - Lightweight and High-Strength FRP Pipes in Various Styles

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m

- Supply Capability:

- 30000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

PRODUCT DESCRIPTION

1.PIPE INTRODUCTION

It is the ideal product for the transportations of the chemicals, drinking water, waste water, waste gas and sewer.

2.CHARACTERISTICS

• Corrosion resistance High mechanical property

• Low friction coefficient

• Light weight

• Non toxic

• Maintenance free

• Long life span

3.PRODUCTION RANGE

Any type and specification RPMP of diameter DN400-DN4000 and pressure PN0.25-PN2.5MPa can be produced. Also, we can provide the customized product according to user’s specific requirements.

TECHNICAL DATA

Stiffness | SN3750 | SN5000 | SN10000 | ||||||

Pressure | 0.25 | 0.6 | 1.0 | 0.25 | 0.6 | 1.0 | 0.25 | 0.6 | 1.0 |

400 | 6.1 | 6.1 | 5.9 | 6.7 | 6.7 | 6.4 | 8.1 | 8.1 | 7.87 |

500 | 7.2 | 7.2 | 7.1 | 8 | 8 | 7.7 | 11.4 | 9.6 | 9.4 |

600 | 8.7 | 8.3 | 8.3 | 9.6 | 9.6 | 9.2 | 12.1 | 11.7 | 11 |

700 | 9.7 | 9.7 | 9.4 | 11.2 | 11.2 | 10.4 | 13.8 | 13.2 | 12.5 |

800 | 11.6 | 11.3 | 10.6 | 12.8 | 12.5 | 11.7 | 15.5 | 15 | 14.2 |

900 | 13.4 | 12.5 | 11.7 | 14.8 | 13.8 | 12.9 | 19.3 | 16.4 | 15.8 |

1000 | 14.6 | 13.7 | 13 | 16.2 | 15.1 | 14.4 | 20.7 | 18 | 17.3 |

1100 | 16.1 | 14.9 | 14.2 | 17.9 | 16.5 | 15.6 | 23 | 19.8 | 18.9 |

1200 | 17.2 | 16.1 | 15.4 | 19.6 | 17.9 | 16.9 | 24.7 | 21.5 | 20.6 |

1400 | 20.4 | 18.4 | 17.7 | 22.7 | 20.5 | 19.5 | 29.2 | 24.8 | 23.8 |

1500 | 22 | 19.9 | 18.7 | 24.4 | 22.1 | 20.7 | 31.4 | 26.3 | 25.3 |

COMPANT DESCRIPTION

CNBM,China National Building Materials Group is a state owned enterprise in charge of administrative affairs in china building materials industry. Established in 1984, CNBM is a large group corporation of building materials with total assets of 25 billion RMB and a total staff of 30,000.CNBM now owns 200 subordinating firms of solely owned and joint-venture companies.

FAQ

Q1.What's your sample policy?

A:We can supply the sample if we have ready parts in stock, but the customers have to pay the courier cost.

Q2.Can you produce according to the samples?

A: Yes, we can produce or modify the products according to your request.

Q3.How do you deliver the goods to my country?

A:We can provide international express, such as DHL, EMS, UPS, FedEx, etc. We select air freight and sea freight upon your requests. Quotations if without mentioning the shipping costs are shipping fee excluded.

Q4.How much does it cost to ship to my country?

A:When you goanna to place an order, please contact us, because different country has different freight.

Q5.How to get the catalogue?

A:please contact us and tell us what you are looking for.

We will try our best to meet customers' demands. Welcome you come here to visit us. We sincerely welcome partners around the world to establish business cooperation with us on the basis of mutual trust, benefit and development.

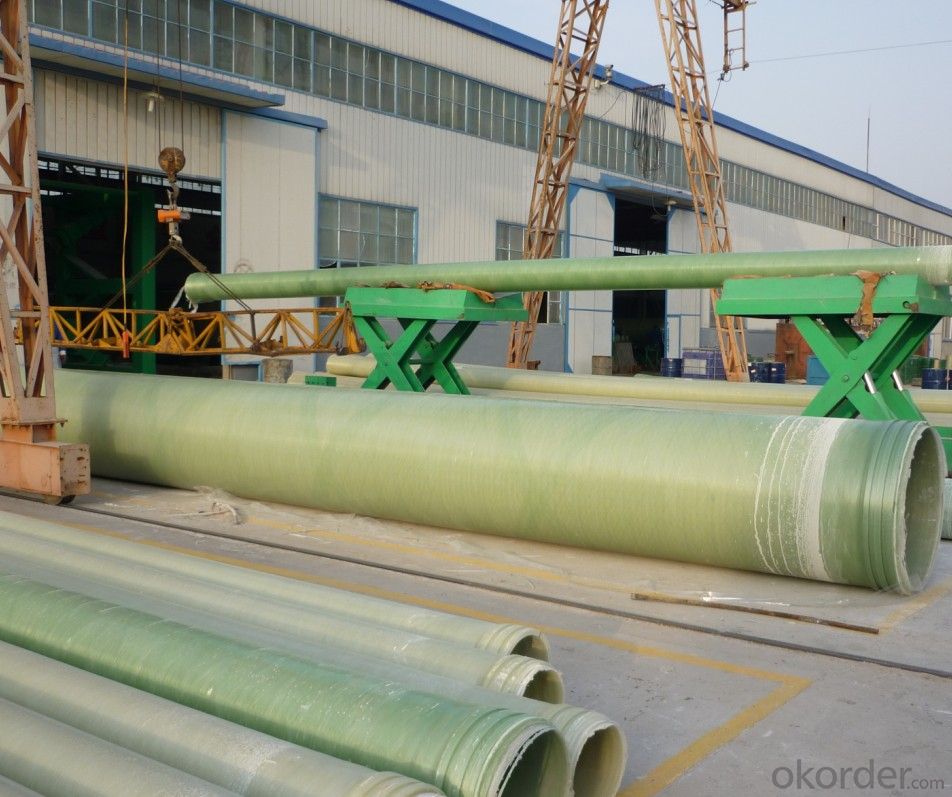

PICTURES

- Q: Can FRP pultrusion profiles be used in the construction of water slides?

- Yes, FRP pultrusion profiles can be used in the construction of water slides. FRP, or fiberglass reinforced plastic, offers excellent strength, durability, and corrosion resistance, making it a suitable material for water slide components. The pultrusion process allows for the production of customized profiles with specific shapes and dimensions, ensuring compatibility with water slide design requirements. Additionally, FRP's lightweight nature simplifies installation and maintenance while providing a safe and enjoyable experience for water slide users.

- Q: Can FRP pultrusion profiles be used in the transportation and logistics industry?

- FRP pultrusion profiles have the capability to be utilized in the transportation and logistics sector. They possess a multitude of advantages that render them suitable for diverse applications within this industry. To begin with, FRP pultrusion profiles are both lightweight and exceptionally robust, ensuring durability. This characteristic makes them highly suitable for implementation in transportation vehicles such as trucks, trailers, and containers, where weight reduction is crucial for enhancing fuel efficiency and minimizing emissions. Despite their lightweight nature, FRP pultrusion profiles are capable of enduring heavy loads and harsh environmental conditions, thereby guaranteeing their reliability and longevity. Furthermore, FRP pultrusion profiles exhibit remarkable resistance to corrosion. Unlike conventional materials like steel or aluminum, FRP does not succumb to rust or corrosion when subjected to moisture or chemicals. This renders FRP profiles apt for applications in transportation and logistics that involve exposure to corrosive substances like saltwater, chemicals, or acidic environments. By incorporating FRP pultrusion profiles, companies can curtail maintenance expenses associated with corrosion and prolong the lifespan of their equipment. In addition, FRP pultrusion profiles offer flexible design options. They can be manufactured in a myriad of shapes, sizes, and configurations to cater to the specific requirements of transportation and logistics applications. Whether it entails structural components, platforms, flooring, or supports, FRP profiles can be tailored to accommodate diverse needs, thereby ensuring optimal performance and functionality. Moreover, FRP pultrusion profiles possess exceptional electrical and thermal insulation properties. This renders them suitable for applications in which electrical conductivity needs to be minimized or thermal insulation is necessary. Within the transportation and logistics industry, this feature can be advantageous for applications like insulation for refrigerated containers or electrical insulation for specialized vehicles. In conclusion, FRP pultrusion profiles are highly suitable for implementation in the transportation and logistics sector. Their lightweight, robust, corrosion-resistant, and customizable nature, combined with their electrical and thermal insulation properties, render them a dependable choice for diverse applications within this field.

- Q: What are pultrusion materials used for?

- Various sections of Glass Fiber Reinforced Plastic Pultruded sections can be produced with different sections of the die. The profile has the characteristics of high strength, corrosion resistance and light weight

- Q: Are FRP pultrusion profiles suitable for the manufacturing of boat hulls?

- Boat hulls can be effectively manufactured using FRP pultrusion profiles. These profiles possess numerous advantages that render them perfect for constructing boat hulls. Firstly, FRP pultrusion profiles are not only lightweight but also exceptionally sturdy and durable. Consequently, they are well-suited for boat hulls as their lightweight nature enhances fuel efficiency and enables increased speed. Moreover, their impressive strength-to-weight ratio guarantees that the boat can endure the rigors of the water without compromising its structural integrity. Secondly, FRP pultrusion profiles exhibit exceptional resistance to corrosion. This characteristic is of utmost importance for boat hulls, which are constantly exposed to water, salt, and other corrosive agents. The corrosion resistance of FRP pultrusion profiles ensures that the boat hull remains intact and maintains its performance over time, thus minimizing the need for frequent maintenance and repairs. Furthermore, FRP pultrusion profiles offer great design flexibility. They can be effortlessly molded into diverse shapes and sizes, thereby facilitating customization and optimization of boat hull designs. This flexibility empowers boat manufacturers to create hulls that are both functional and visually appealing. In addition to their strength, durability, corrosion resistance, and design flexibility, FRP pultrusion profiles also possess excellent electrical and thermal insulation properties. These properties are particularly important for boat hulls as they effectively prevent the passage of electrical currents and heat through the hull, thereby ensuring the safety and comfort of passengers and crew. Overall, FRP pultrusion profiles present an outstanding solution for boat hull manufacturing. Their lightweight, robust, and corrosion-resistant attributes, in conjunction with their design flexibility and insulation capabilities, make them an ideal choice for boat manufacturers seeking to produce high-performance and long-lasting vessels.

- Q: Are FRP pultrusion profiles resistant to fungal growth?

- Yes, FRP pultrusion profiles are highly resistant to fungal growth. The composite materials used in FRP pultrusion, such as fiberglass and resin, do not provide a suitable environment for fungi to grow. Additionally, the smooth surface of FRP profiles makes it difficult for fungi to attach and thrive. Hence, FRP pultrusion profiles are an excellent choice for applications where resistance to fungal growth is required.

- Q: Are FRP pultrusion profiles resistant to fungal growth?

- FRP pultrusion profiles are generally resistant to fungal growth. The composite materials, like resins and fibers, used in pultrusion possess inherent resistance to biological degradation, including attacks from fungi. The non-porous nature of FRP pultrusion profiles also poses difficulties for fungi to penetrate and grow on the surface. Furthermore, the manufacturing process involves curing the composite materials at high temperatures, which adds to their resistance against fungal growth. However, it is important to acknowledge that no material is entirely impervious to fungal growth in all conditions. Factors such as high humidity, prolonged exposure to moisture, and inadequate maintenance practices can still contribute to fungal growth on FRP pultrusion profiles, albeit to a lesser extent compared to materials like wood or metal. Regular inspection and appropriate cleaning are crucial to sustain the fungal resistance of FRP pultrusion profiles throughout their lifespan.

- Q: Can FRP pultrusion profiles be used in automotive applications?

- Yes, FRP pultrusion profiles can be used in automotive applications. They offer several advantages such as high strength-to-weight ratio, corrosion resistance, and design flexibility. Additionally, FRP pultrusion profiles can withstand harsh environmental conditions, making them suitable for various automotive components, including body panels, structural supports, and interior parts.

- Q: Are FRP pultrusion profiles resistant to chemicals used in mining operations?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles are highly resistant to chemicals commonly used in mining operations. The composite material used in FRP pultrusion profiles is inherently corrosion-resistant and can withstand the harsh chemical environment typically encountered in mining. Additionally, FRP pultrusion profiles offer excellent resistance to acids, alkalis, solvents, and other chemicals, making them a durable and reliable choice for mining applications.

- Q: Are FRP pultrusion profiles resistant to chemicals used in pharmaceutical manufacturing?

- Yes, FRP pultrusion profiles are generally resistant to chemicals used in pharmaceutical manufacturing. The use of high-quality resins and fiberglass reinforcement in the manufacturing process makes FRP pultrusion profiles highly resistant to a wide range of chemicals, acids, and alkalis commonly used in pharmaceutical manufacturing. However, it is always advisable to consult with the manufacturer or supplier to ensure that the specific chemicals used in the manufacturing process are compatible with the FRP profiles.

- Q: Can FRP pultrusion profiles be used in modular construction?

- Yes, FRP pultrusion profiles can be used in modular construction. FRP (Fiber Reinforced Polymer) pultrusion profiles offer several advantages such as high strength-to-weight ratio, corrosion resistance, and design flexibility. These properties make them suitable for various applications in modular construction, including structural elements, cladding, and panel systems. Additionally, FRP pultrusion profiles can be easily molded into different shapes and sizes, making them compatible with the modular construction approach, where standardized components are assembled to create a larger structure.

Send your message to us

FRP Pultrusion Profiles - Lightweight and High-Strength FRP Pipes in Various Styles

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m

- Supply Capability:

- 30000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords