FRP Pultrusion Profiles for Molded Gratings - Insulation and Anti-Corrosion

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 8000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification:

FRP molded grating made of vertical and horizontal continuous fiberglass fully soaked in unsaturated polyester resin giving perfect bi-directional mechanical properties. Combining unmatched corrosion resistance with strength, long life and safety, molded grating provide the ultimate in reliable performance, even in the most demanding corrosive conditions. Besides, it is easy to cut and install. CNBM offer the widest selection with panel sizes, colors and slip resistant surfaces, clients can avail FRP grating your specific requirements.

Product Features:

- Light but high loaded strength

- High anti-corrosion and anti-aging

- Easy installation and maintenance

- Low maintenance

- Non-conductive

- Lowest in life cycle cost

- Corrosion Resstance

- Anti-slippery

- Various sizes and color available

Colour Design:

To satisfy customer's design project, CNBM grating offers a wide selection of grating colors to choose from. The standard colors available for fiberglass grating as following:

- Blue

- Red

- Yellow

- Green

- Light Grey

- Dark Grey

Custom colors of fiberglass grating may be available upon request, you can contact us learn more.

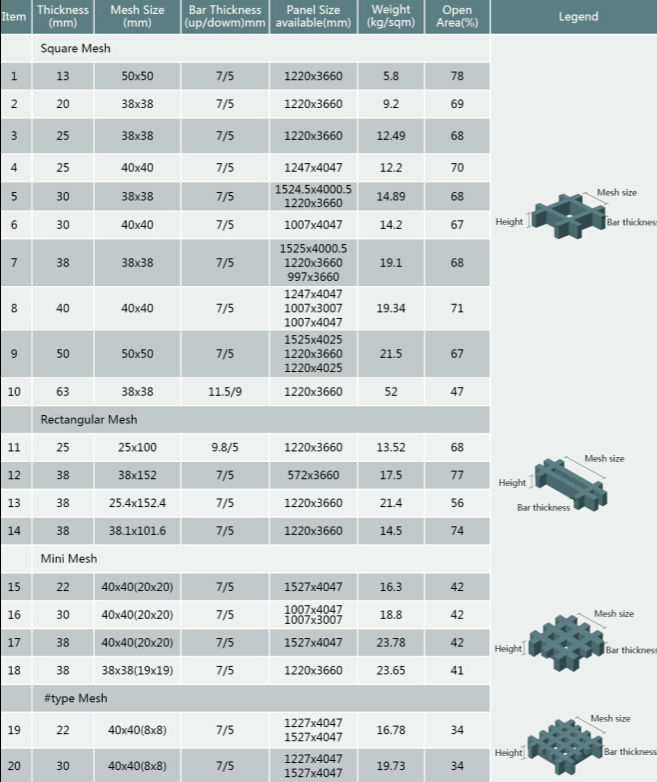

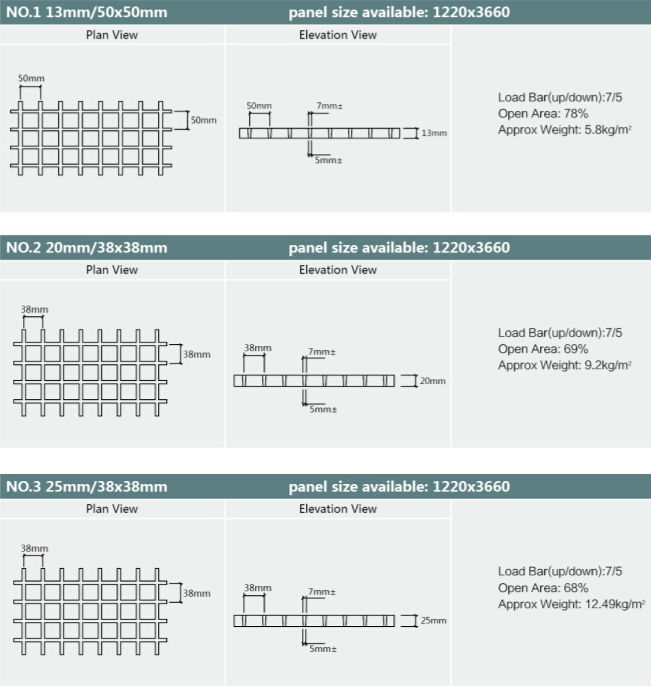

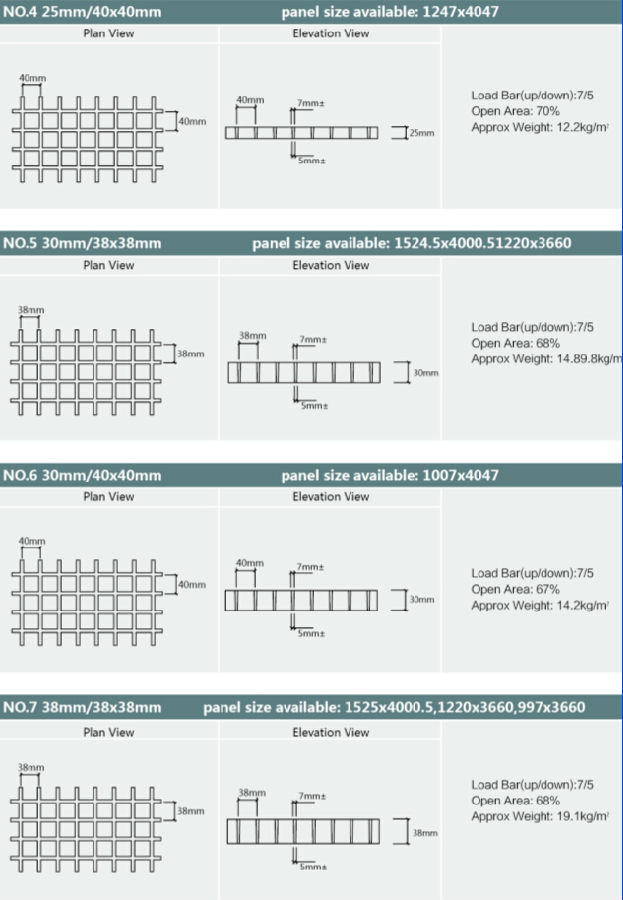

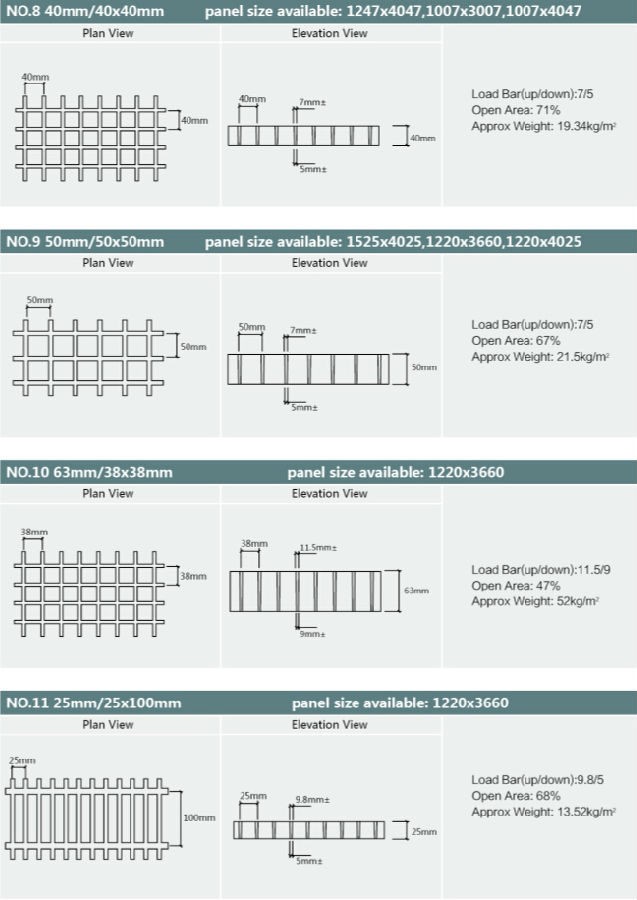

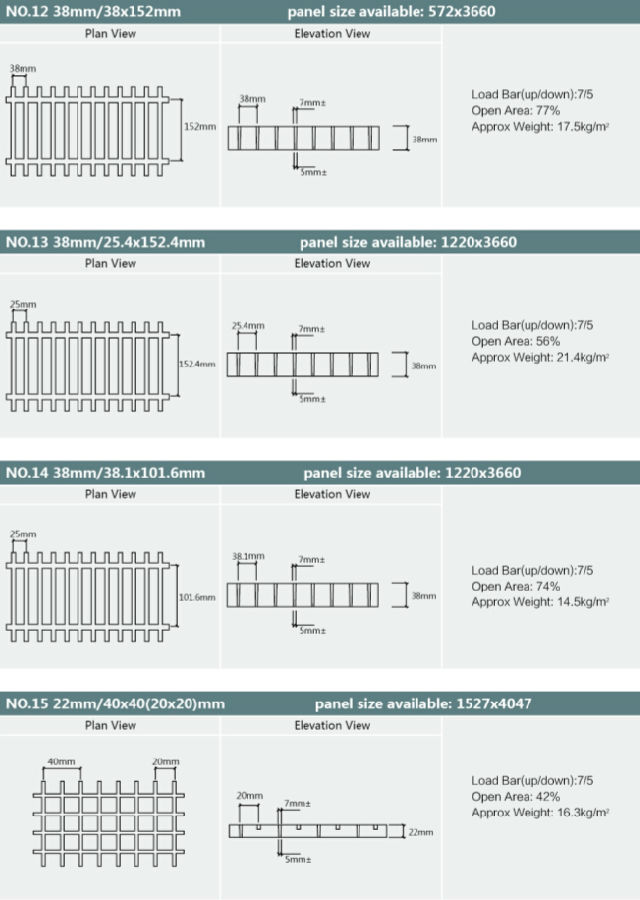

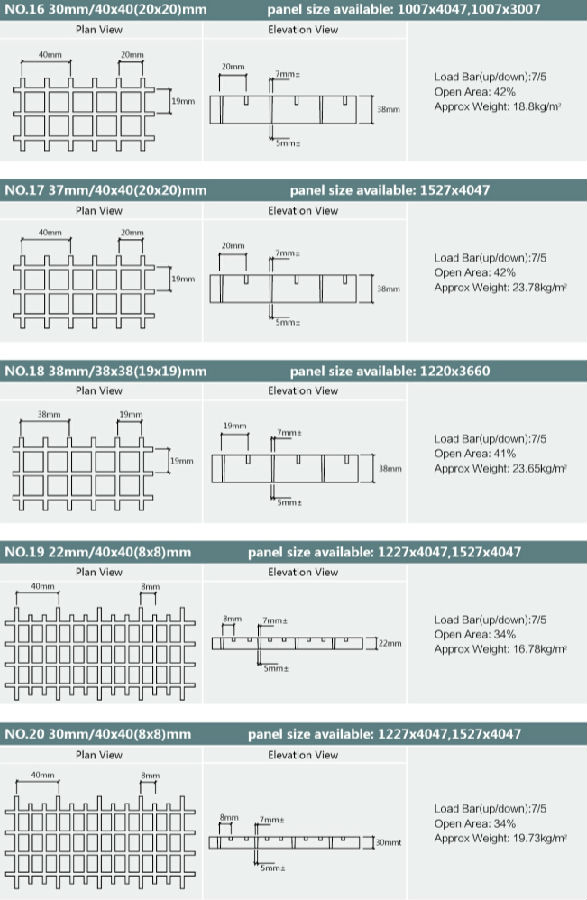

Moded Grating Sizes List:

- Q: Can FRP pultrusion profiles be used in the renewable energy sector?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles can be effectively used in the renewable energy sector. These profiles possess excellent strength-to-weight ratio, corrosion resistance, and durability, making them ideal for various renewable energy applications. They can be utilized in the manufacturing of wind turbine blades, solar panel frames, structural components for hydroelectric power systems, and much more. Additionally, FRP pultrusion profiles offer design flexibility, allowing for customization to specific project requirements.

- Q: Are FRP pultrusion profiles resistant to hail or impact damage?

- FRP pultrusion profiles exhibit exceptional resistance to both hail and impact damage. The incorporation of reinforcing fibers such as carbon or glass, along with a polymer resin matrix, grants these profiles unparalleled strength and durability. When compared to materials like wood, steel, or aluminum, FRP pultrusions offer significantly superior impact resistance. These profiles are specifically engineered to endure even the harshest environmental conditions, including hailstorms. The composite composition of FRP enables it to effectively absorb and distribute the energy generated by impacts, effectively preventing the formation of cracks or fractures. As a result, they are an ideal choice for various applications that necessitate protection against hail or impact damage, such as building facades, bridges, handrails, and utility poles. Moreover, FRP pultrusion profiles possess an impressive strength-to-weight ratio, meaning they can withstand heavy impacts without undermining their structural integrity. Furthermore, they are non-corrosive, making them impervious to rust or degradation caused by hail or impact. To summarize, the composite construction and exceptional strength-to-weight ratio of FRP pultrusion profiles render them highly resistant to hail or impact damage. They offer a reliable and long-lasting solution for applications that demand durability and resilience in the face of harsh environmental conditions.

- Q: What is the maximum length of FRP pultrusion profiles that can be manufactured?

- The length at which FRP pultrusion profiles can be manufactured is influenced by various factors, including the specific manufacturing process, equipment capacity, and transportation limitations. Generally, these profiles can range in length from a few feet to several hundred feet, but there are practical limitations that must be taken into account. Firstly, the size and capacity of the pultrusion equipment used in the manufacturing process often determine the length restrictions of the profiles. Different pultrusion machines have different capabilities, with length capacities varying from a few feet to over 100 feet. Manufacturers must consider the limitations of their available equipment when determining the maximum length they can produce. In addition, transportation and logistical constraints can also impact the maximum length of FRP pultrusion profiles. Longer profiles can be more difficult to transport due to restrictions on road transport, shipping containers, or handling capabilities. These limitations may vary depending on the region, infrastructure, and available transportation methods. It is worth noting that longer profiles may also face challenges in terms of quality control and dimensional stability during the manufacturing process. As the length increases, it becomes more challenging to maintain consistent mechanical properties and effectively control the curing process. Therefore, while there is no fixed maximum length for FRP pultrusion profiles, it is crucial for manufacturers to consider the technical capabilities of their equipment, transportation logistics, and quality control factors when determining the practical limit for the length of their products.

- Q: Can FRP pultrusion profiles be used in agricultural structures?

- Yes, FRP pultrusion profiles can certainly be used in agricultural structures. They offer several advantages such as high strength-to-weight ratio, corrosion resistance, and durability, making them suitable for various applications in the agricultural industry. These profiles can be used in structures like greenhouse frames, livestock enclosures, support beams, fencing, and other agricultural infrastructure.

- Q: Can FRP pultrusion profiles be used in the automotive industry?

- Yes, FRP (Fiber Reinforced Plastic) pultrusion profiles can definitely be used in the automotive industry. FRP pultrusion profiles offer several advantages that make them suitable for automotive applications. Firstly, FRP pultrusion profiles are lightweight, which is a crucial factor in the automotive industry as it helps in improving fuel efficiency and reducing overall vehicle weight. Lighter vehicles have lower energy consumption and emissions, making them more environmentally friendly. Secondly, FRP pultrusion profiles have excellent strength-to-weight ratio. This means they can provide high strength and stiffness while being lightweight. This property makes them ideal for structural components in automobiles, such as chassis, body panels, and support structures. Furthermore, FRP pultrusion profiles are highly corrosion-resistant, which is a significant advantage in automotive applications. Vehicles are often exposed to harsh environmental conditions, including moisture, salt, and chemicals. The corrosion resistance of FRP helps in ensuring the longevity and durability of automotive components, even in challenging environments. Additionally, FRP pultrusion profiles have good impact resistance, which is crucial for automotive safety. They can absorb and dissipate energy during impacts, reducing the risk of injury in case of accidents. Moreover, FRP pultrusion profiles can be customized and engineered to meet specific design requirements, allowing for versatility in automotive applications. They can be designed to have specific mechanical properties, shapes, and sizes, making them suitable for various automotive components. Overall, the lightweight, high strength, corrosion resistance, impact resistance, and customization options make FRP pultrusion profiles an excellent choice for the automotive industry. They offer numerous benefits, including improved fuel efficiency, enhanced safety, and prolonged component life, making them a viable alternative to traditional materials in automotive applications.

- Q: Are FRP pultrusion profiles resistant to UV degradation?

- Yes, FRP pultrusion profiles are generally resistant to UV degradation. Pultrusion profiles made from fiberglass reinforced plastic (FRP) are manufactured using a combination of resin and glass fibers. The resin used in the manufacturing process is typically formulated to provide resistance to UV radiation. This UV resistance helps to protect the FRP pultrusion profiles from the harmful effects of prolonged exposure to sunlight. FRP pultrusion profiles have been extensively tested and have demonstrated excellent resistance to UV degradation. They are commonly used in outdoor applications where they are exposed to sunlight, such as in construction, infrastructure, and marine industries. UV resistance ensures that the FRP pultrusion profiles maintain their structural integrity, color, and aesthetic appearance over an extended period of time. However, it is important to note that the level of UV resistance may vary depending on the specific formulation of the resin used in the manufacturing process. Different manufacturers may use different resins with varying levels of UV stabilizers. It is recommended to consult with the manufacturer or supplier to ensure that the specific FRP pultrusion profiles being used are designed to withstand the UV conditions of the intended application. Regular maintenance and periodic inspection of the FRP pultrusion profiles are also important to ensure their long-term UV resistance. This may include cleaning, applying protective coatings, or using UV-blocking additives if necessary. By taking these precautions, the UV resistance of FRP pultrusion profiles can be further enhanced, ensuring their durability and longevity in outdoor environments.

- Q: Are FRP pultrusion profiles resistant to fading or discoloration?

- FRP pultrusion profiles possess exceptional resistance against fading and discoloration. This attribute stems from the inherent properties of the materials employed in their construction. Typically, FRP profiles are fabricated using a blend of fiberglass reinforcements and a polymer resin matrix, both of which inherently resist UV radiation and other environmental factors that lead to fading and discoloration. The polymer resin matrix used in FRP profiles is specifically designed to exhibit outstanding chemical resistance and UV stability. As a result, the profiles retain their original color and appearance for an extended duration. This makes FRP pultrusion profiles an ideal choice for outdoor applications, where exposure to sunlight and harsh weather conditions is prevalent. Additionally, the pultrusion manufacturing process ensures that the color of FRP profiles remains consistent throughout their entire cross-section. Consequently, even in the presence of minor surface damage or wear, the underlying color of the profile remains unchanged, ensuring a uniform appearance. In summary, FRP pultrusion profiles offer unparalleled resistance against fading and discoloration, making them a resilient and long-lasting option for a wide range of applications, including construction, infrastructure, transportation, and more.

- Q: Are FRP pultrusion profiles resistant to automotive fluids?

- Yes, FRP pultrusion profiles are generally resistant to automotive fluids. The inherent chemical resistance and durability of the fiberglass-reinforced plastic make it suitable for withstanding exposure to various automotive fluids such as oils, fuels, and coolants. However, it is essential to consider the specific type of fluid and consult the manufacturer's guidelines to ensure the optimal performance and longevity of the FRP profiles in automotive applications.

- Q: Can FRP pultrusion profiles be used in the construction of safety barriers?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles can be effectively used in the construction of safety barriers. FRP pultrusion profiles offer several advantages over traditional materials like steel or concrete when it comes to safety barrier applications. Firstly, FRP pultrusion profiles are incredibly strong and durable. They have high tensile strength, which means they can withstand heavy loads and impacts without deforming or breaking. This makes them suitable for withstanding the forces that safety barriers may encounter, such as vehicular collisions or other accidents. Secondly, FRP pultrusion profiles are lightweight. Compared to steel or concrete, FRP is significantly lighter, making it easier to transport, install, and handle during construction. The lightweight nature of FRP also reduces the overall weight of the safety barrier structure, which can be an advantage in terms of ease of installation and cost-effectiveness. Additionally, FRP pultrusion profiles have excellent corrosion resistance. Unlike steel, FRP is not susceptible to rust or corrosion, which can compromise the integrity and safety of the barrier over time. This makes FRP an ideal material for safety barriers that are exposed to outdoor environments or harsh weather conditions. Furthermore, FRP pultrusion profiles are non-conductive and non-magnetic, which can be advantageous in certain safety barrier applications. For example, in areas where electrical or magnetic interference is a concern, such as near power lines or sensitive equipment, FRP barriers can provide an extra layer of safety by avoiding any potential electrical or magnetic hazards. Overall, FRP pultrusion profiles offer a reliable and efficient solution for constructing safety barriers. Their strength, durability, lightweight nature, corrosion resistance, and non-conductive properties make them a suitable choice for a wide range of safety barrier applications.

- Q: Are FRP pultrusion profiles resistant to fuels?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles are generally resistant to fuels. The combination of high-strength fibers and a polymer matrix makes FRP profiles highly resistant to various chemicals, including fuels. This resistance is primarily due to the non-reactive nature of the polymer matrix, which prevents the fuel from causing any significant degradation or damage to the profiles. FRP pultrusion profiles are commonly used in industries where exposure to fuels is a common occurrence, such as the automotive, aerospace, and oil and gas sectors. These profiles have been extensively tested and proven to withstand prolonged contact with fuels without experiencing any detrimental effects. Additionally, FRP profiles offer several advantages over traditional materials like steel or aluminum in fuel-related applications. They are corrosion-resistant, lightweight, and have excellent dimensional stability, making them ideal for use in environments where the risk of fuel exposure is high. However, it is important to note that the specific resistance of FRP pultrusion profiles to fuels may vary depending on the type and concentration of the fuel, as well as the specific composition of the FRP material. Therefore, it is always recommended to consult with the manufacturer or supplier to ensure that the chosen FRP profiles are suitable for the specific fuel-related application.

Send your message to us

FRP Pultrusion Profiles for Molded Gratings - Insulation and Anti-Corrosion

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 8000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords