FRP Pultrusion Profiles Fiberglass Tube with High Strength for Mop

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

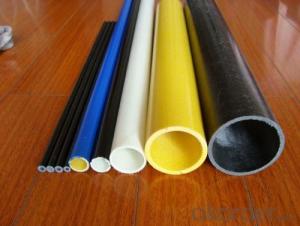

Specifications of Fiberglass Tube with High Strength for Mop:

1.Consistent cross section

2.High corrosion resistance

3.Wide temperature range

4.UV resistant Inhibited

5.High strength

Applications of Fiberglass Tube with High Strength for Mop:

1) Outdoor activities: tent Pole, kite Rod, arrow shaft, ski pole, fishing rod, golf shaft, sail batten, hockey stick, kick board, skate boards, paddle shafts, bows and arrows, crossbows, golf shafts, slide guides, boat, kayak

2) Tool: umbrella shaft, umbrella rod, curtain rod, fence post, rail, handrail, frame for cases and bags, flag pole, oil sucker rods, bolts, stair, ladder, greenhouse structures, scaffold, portable work platforms, cooling tower, luggage rack, window/door frame, sign post, bridge structure, bus bar supports, tool handles, bike flags, flag poles, floor gratings, shoe soles, protective cases for laptops and iPhones

3) Toys: model cars/planes/helicopters, unmanned aerial vehicles, formula-1 race car

4) Vehicle: motor top sticks, u-shaped motor stator wedges, service truck booms, snowmobile track stiffeners, high-end automobile components, bicycle frames, glider, microcar, bodyshell, wind turbine blade.

5) Building: roofing laminate, flat roof, door surrounds, over-door canopies, window canopies and dormers, chimneys, coping systems, insulators, cable conductor, cable tray, antenna, transformer air duct spacer sticks, cable support trays, switch actuators.

- Q: Can FRP pultrusion profiles be used in the transportation and logistics industry?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles can be used in the transportation and logistics industry. FRP pultrusion profiles offer several advantages that make them suitable for various applications in this industry. Firstly, FRP pultrusion profiles are lightweight yet extremely strong and durable. This makes them ideal for use in transportation vehicles, such as trucks, trailers, and containers, where reducing weight is crucial for improving fuel efficiency and reducing emissions. Despite their lightweight nature, FRP pultrusion profiles can withstand heavy loads and harsh environmental conditions, ensuring their reliability and longevity. Secondly, FRP pultrusion profiles are highly corrosion-resistant. Unlike traditional materials, such as steel or aluminum, FRP does not rust or corrode when exposed to moisture or chemicals. This makes FRP profiles suitable for use in transportation and logistics applications that involve exposure to corrosive substances, such as saltwater, chemicals, or acidic environments. By using FRP pultrusion profiles, companies can reduce maintenance costs associated with corrosion and prolong the lifespan of their equipment. Additionally, FRP pultrusion profiles offer design flexibility. They can be manufactured in various shapes, sizes, and configurations to meet the specific requirements of transportation and logistics applications. Whether it is for structural components, platforms, flooring, or supports, FRP profiles can be customized to fit different needs, ensuring optimal performance and functionality. Moreover, FRP pultrusion profiles have excellent electrical and thermal insulation properties. This makes them suitable for applications where electrical conductivity needs to be minimized or thermal insulation is required. In the transportation and logistics industry, this can be beneficial for applications such as insulation for refrigerated containers or electrical insulation for specialized vehicles. In summary, FRP pultrusion profiles are well-suited for the transportation and logistics industry. Their lightweight, strong, durable, corrosion-resistant, and customizable nature, along with their electrical and thermal insulation properties, make them a reliable choice for various applications in this sector.

- Q: Are FRP pultrusion profiles resistant to biological growth, such as mold or mildew?

- FRP pultrusion profiles are highly resistant to biological growth, such as mold and mildew. These profiles have a non-porous structure that makes it difficult for microorganisms to attach and grow. They are typically made with a combination of resin and glass fibers, both of which naturally resist biological growth. In contrast to materials like wood or metal, FRP does not create an ideal environment for mold or mildew. The smooth and non-porous surface of FRP prevents moisture absorption, which is necessary for microorganisms to thrive. Additionally, FRP materials lack organic compounds that can support the growth of mold or mildew, thus enhancing their resistance to biological degradation. When it comes to applications that require resistance to biological growth, FRP pultrusion profiles offer a significant advantage over other materials. They are commonly used in environments with high humidity, moisture, or water exposure, such as marine, agricultural, or wastewater treatment facilities. Furthermore, FRP profiles are frequently employed indoors in areas where mold or mildew growth is a concern, such as sanitary areas or food processing plants. Overall, FRP pultrusion profiles are an excellent solution for combating biological growth, including mold and mildew. Their non-porous nature, combined with the inherent resistance of the materials used in their manufacturing, ensures durability and longevity in environments where microbial growth is a potential issue.

- Q: Are FRP pultrusion profiles resistant to automotive fluids?

- FRP pultrusion profiles, commonly known as Fiber Reinforced Polymer profiles, possess a general resistance to automotive fluids. FRP, an abbreviation for Fiber Reinforced Polymer, is a composite material comprising a combination of fibers and a polymer matrix. The fibers utilized in FRP, such as fiberglass, carbon, or aramid, exhibit exceptional resistance to various automotive fluids, including oils, fuels, and coolants. The polymer matrix found in FRP profiles usually consists of a thermosetting resin, namely polyester, vinyl ester, or epoxy. These resins are renowned for their chemical resistance properties, which contribute to the high resistance of FRP pultrusion profiles towards a wide array of automotive fluids. They can endure exposure to different fluids without significant deterioration or loss of mechanical properties. It is important to acknowledge that the specific resistance of FRP pultrusion profiles to automotive fluids may differ based on the resin type and the composite material's precise composition. As a result, it is advisable to consult the manufacturer or supplier of the FRP profiles to verify their suitability for the intended application and the specific automotive fluids they may encounter.

- Q: Are FRP pultrusion profiles resistant to termites or other pests?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles are inherently resistant to termites and other pests. Unlike traditional wood or metal materials, FRP profiles do not provide a food source for termites or any other pests. FRP is composed of a combination of reinforced fibers and a polymer matrix, typically made of fiberglass and resin. These materials are not appealing to pests and do not provide any nutritional value, making FRP profiles highly resistant to termite damage or infestation. This resistance to pests is one of the many advantages of using FRP pultrusion profiles in various applications, especially in outdoor or humid environments where termites are commonly found.

- Q: Can FRP pultrusion profiles be used in the construction of wastewater treatment tanks?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles can be effectively used in the construction of wastewater treatment tanks. FRP pultrusion profiles are known for their high strength-to-weight ratio, corrosion resistance, and durability, making them an ideal choice for applications in harsh environments such as wastewater treatment facilities. FRP pultrusion profiles are made by pulling continuous fibers, typically glass or carbon, through a resin bath and then through a heated die to form the desired shape. This process results in profiles with consistent cross-sections and excellent mechanical properties. In the construction of wastewater treatment tanks, FRP pultrusion profiles can be used for a variety of purposes. They can be employed as structural elements, such as beams, columns, and bracing systems, providing the necessary strength and stiffness to support the tank structure. FRP profiles can also be used as reinforcement in concrete structures, enhancing their durability and resistance to chemical attack from the wastewater. Furthermore, FRP pultrusion profiles can be designed to resist the corrosive effects of the chemicals and gases present in wastewater treatment tanks. Unlike traditional materials like steel or concrete, FRP is highly resistant to corrosion, ensuring a longer service life and reduced maintenance costs. Additionally, FRP profiles offer advantages in terms of installation and transportation. They are lightweight, allowing for easier handling and reduced labor requirements during construction. The modular nature of FRP profiles also facilitates quick assembly and disassembly, making maintenance and modifications more convenient. Overall, the use of FRP pultrusion profiles in the construction of wastewater treatment tanks provides numerous benefits, including high strength, corrosion resistance, durability, and ease of installation. These advantages make FRP a reliable and cost-effective choice for wastewater treatment facilities.

- Q: Are FRP pultrusion profiles impact resistant?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles are known for their high impact resistance. The combination of strong reinforcing fibers and a polymer matrix makes them highly durable and able to withstand significant impact forces without breaking or deforming.

- Q: Are FRP pultrusion profiles resistant to fungal growth?

- Yes, FRP pultrusion profiles are highly resistant to fungal growth. The composite materials used in FRP pultrusion, such as fiberglass and resin, do not provide a suitable environment for fungi to grow. Additionally, the smooth surface of FRP profiles makes it difficult for fungi to attach and thrive. Hence, FRP pultrusion profiles are an excellent choice for applications where resistance to fungal growth is required.

- Q: How do FRP pultrusion profiles perform in chemical processing plants?

- FRP pultrusion profiles perform exceptionally well in chemical processing plants. They are highly resistant to corrosion, chemicals, and extreme temperatures, making them an ideal choice for various applications. Their superior strength-to-weight ratio allows for easy installation and reduces maintenance costs. Additionally, FRP profiles offer excellent electrical insulation properties, making them safe and reliable in hazardous environments. Overall, FRP pultrusion profiles are a reliable and durable solution for chemical processing plants.

- Q: Are FRP pultrusion profiles non-conductive?

- FRP pultrusion profiles are non-conductive because they consist of reinforced fibers, usually fiberglass, and a polymer resin matrix. The fiberglass fibers provide strength and stiffness, while the polymer resin acts as a binder. One of the main advantages of FRP pultrusion profiles is their excellent electrical insulation properties. Unlike metals, which conduct electricity, FRP profiles do not. This makes them ideal for applications that require electrical insulation. In addition to being non-conductive, FRP pultrusion profiles also offer other advantages like corrosion resistance, a high strength-to-weight ratio, and low maintenance requirements. These properties make them suitable for various applications such as electrical and telecom infrastructure, chemical processing plants, bridges, and building construction. It is worth noting that while FRP pultrusion profiles are non-conductive by default, they can be made conductive if necessary. Special additives or coatings can be added during the manufacturing process to give them conductive properties.

- Q: What are the limitations of using FRP pultrusion profiles?

- When selecting materials for a particular application, it is crucial to take into account several limitations associated with the use of FRP (Fiber Reinforced Polymer) pultrusion profiles. Firstly, FRP pultrusion profiles have limited design flexibility due to their fixed cross-sectional shape, which is a result of the continuous manufacturing process. This restricts the ability to create complex or custom profiles, making them less flexible in design compared to metals or plastics. Secondly, FRP materials are susceptible to UV degradation. Prolonged exposure to sunlight can cause fading, discoloration, and loss of mechanical properties. To ensure long-term durability in outdoor applications, it is necessary to implement proper surface coatings or UV protection measures. Thirdly, FRP pultrusion profiles generally have lower impact resistance compared to metals. While they offer excellent strength-to-weight ratios, they may be more prone to damage from impacts or heavy loads. Therefore, careful handling and structural reinforcement may be necessary to mitigate the risk of damage. Additionally, FRP materials have a relatively high coefficient of thermal expansion compared to metals. This means that they will expand and contract significantly with changes in temperature. Proper allowances and design calculations must be made to ensure dimensional stability and prevent issues such as buckling or warping. Furthermore, FRP pultrusion profiles are generally combustible and can contribute to the spread of fire. While some FRP materials can be formulated with fire-retardant additives, they may still not meet the stringent fire safety requirements of certain applications. In situations where fire resistance is critical, alternative materials with better fire resistance properties may be preferred. Lastly, it is important to consider cost considerations when choosing FRP pultrusion profiles. They can be more expensive compared to traditional materials like steel or aluminum, especially when specialty reinforcements or additives are involved. However, the overall life cycle cost, including maintenance, durability, and weight savings, should be considered to determine the cost-effectiveness of FRP profiles for a specific application. Therefore, it is crucial to carefully evaluate these limitations and compare them against the specific requirements and constraints of the intended application to determine whether FRP pultrusion profiles are the most suitable materials to use.

Send your message to us

FRP Pultrusion Profiles Fiberglass Tube with High Strength for Mop

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords