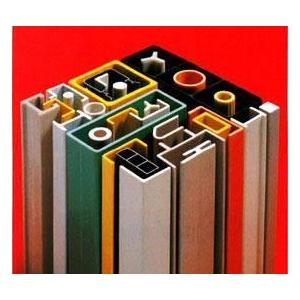

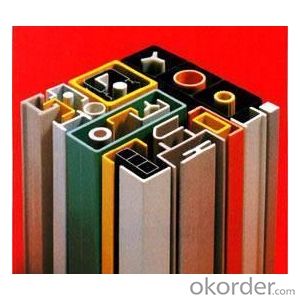

FRP Pultrusion Profiles - High Quality Supplier & Manufacturer

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Brief Introduction

FRP pipe (FRP),FRP Tube,Fiber winding FRP tubes with reliability, safety and efficiency, mainly used for buried tube and long-distance pipelines, high strength, corrosion resistance, long service life, operation and maintenance costs low characteristic, can save money for construction projects.

2.Characteristics

1)high strength: the proportion of FRP for 1.65-2.0. For the same length, diameter of unit weight only one-third of the carbon steel and cast iron pipe of FRP pipes only 1/5, prestressed concrete pipe 1/10, in construction, reduced cost, improve the lifting speed, etc.

2)the hydraulic characteristics of good: this o: this one characteristic in water supply and drainage field application, intion, intion, in particular the hydraulic characteristics.

2.1pipeline pump can save cost.

2.2 reduce diameter size.

2.3 to shorten the time of the pump.

2.4 FRP pipe culvert scaling, not long, make water without rack cleaner by secondary pollution.

3)water resistant, corrosion resistance of FRP pipes excellent corrosion resistance, anti-corrosion, reduced costced cost prolong the life, At the same time as the water conveyance that does not rust, not by a second pollution. Also can used for conveying sewage and sludge, the sea, and other media.

4)compression: the technique requirements, design and manufacture of the pressure piping and fittings, technical requirements of 1.5 times the pressure hydrostatic test.

5) the interface sealing, no leakage, not crack, increase water safety and reliability.

6)non-toxic, can be used for conveying water.

3.Application

A water transport lnsport line pipe and pipes

A sewage pipe, water pipe

A irrigated agriculture tube

4.Specification

Controlled by computer, in accordance with the provisions in the mandrel glass fiber winding with the same process manufacturing lining, gel according to design linear and good after winding layer thickness, and will be mixed with the mortar quartz resin in structure layer, finally winding outside layer.

5.FAQ

Packaging & Delivery

Packaging Details: | woven belt |

Delivery Detail: | 5-7 days,according to the order |

- Q: How are FRP pultrusion profiles manufactured?

- FRP pultrusion profiles are manufactured through a continuous process that involves pulling fiber reinforcement material (such as fiberglass) through a resin bath, impregnating it with a thermosetting resin. The saturated fibers are then pulled through a heated die, which shapes the profile to the desired cross-sectional geometry. As the resin cures, the profile hardens and is cut into desired lengths. This efficient and automated process allows for the production of high-strength and lightweight FRP profiles.

- Q: Can FRP pultrusion profiles be used for structural applications?

- Yes, FRP pultrusion profiles can be used for structural applications. They are commonly utilized in various industries such as construction, automotive, aerospace, and marine. FRP pultrusion profiles offer high strength-to-weight ratio, excellent corrosion resistance, and durability, making them suitable for structural components like beams, columns, and trusses. Additionally, they can be designed to meet specific load requirements and offer design flexibility.

- Q: What are the different types of FRP pultrusion profiles available?

- There are several different types of FRP (Fiber Reinforced Polymer) pultrusion profiles available, each designed to meet specific application requirements and performance criteria. Some of the most common types include: 1. Standard shapes: These profiles are commonly used in various industries and applications. They come in a range of sizes and shapes, such as round tubes, square tubes, rectangular tubes, and angles. Standard shapes provide versatility and are suitable for a wide range of structural and non-structural applications. 2. Custom profiles: These profiles are specifically designed and manufactured according to customer specifications. Custom profiles offer greater flexibility in terms of shape, dimensions, and reinforcement options. They are often used in unique or specialized applications where standard shapes may not be suitable. 3. Structural profiles: These profiles are designed to provide high strength and stiffness properties. They are commonly used in load-bearing applications where structural integrity is crucial, such as beams, columns, and trusses. Structural profiles are reinforced with additional fibers to enhance their load-bearing capacity. 4. Electrical profiles: These profiles are designed to have excellent electrical insulation properties. They are commonly used in electrical and electronics applications, such as cable trays, busbars, and insulating supports. Electrical profiles offer high dielectric strength and resistance to electrical conductivity. 5. Environmental profiles: These profiles are specially formulated to resist harsh environmental conditions, such as extreme temperatures, UV radiation, or chemical exposure. They are commonly used in outdoor applications, such as structural supports, handrails, and grating systems. Environmental profiles provide long-term durability and resistance to degradation. 6. Fire-retardant profiles: These profiles are designed to have improved fire resistance properties. They are commonly used in applications where fire safety is a concern, such as building construction, transportation, and aerospace. Fire-retardant profiles are formulated with additives that inhibit flame spread and reduce smoke generation. It is important to note that these are just some of the common types of FRP pultrusion profiles available, and there may be other specialized profiles based on specific industry requirements. The selection of the appropriate profile depends on factors such as the intended application, load requirements, environmental conditions, and regulatory standards.

- Q: Are FRP pultrusion profiles resistant to electrical arcing?

- FRP pultrusion profiles are generally resistant to electrical arcing. This is because they are made from non-conductive materials like fiberglass reinforced plastic. These profiles do not conduct electricity, which makes them ideal for applications where electrical arcing or conductivity is a concern. However, it is important to note that the specific resistance to electrical arcing may vary depending on the specific composition and design of the FRP pultrusion profiles. It is recommended to consult with the manufacturer or supplier of the profiles to ensure they meet the required electrical resistance standards for a particular application.

- Q: Are FRP pultrusion profiles resistant to earthquakes?

- FRP (Fiber Reinforced Polymer) pultrusion profiles can offer certain advantages when it comes to earthquake resistance. The inherent properties of FRP materials, such as high strength-to-weight ratio, flexibility, and damping characteristics, contribute to their ability to withstand seismic events. Additionally, FRP pultrusion profiles possess excellent fatigue resistance, which is crucial during earthquake-induced vibrations and aftershocks. One of the key advantages of FRP pultrusion profiles is their lightweight nature. Compared to traditional building materials like steel or concrete, FRP profiles are significantly lighter, reducing the overall mass of the structure. This weight reduction minimizes the inertia forces acting on the building during an earthquake, thus decreasing the potential for damage. Moreover, FRP materials exhibit high flexibility and ductility, allowing them to deform and absorb energy during seismic events. This flexibility helps in distributing the seismic forces more uniformly throughout the structure, reducing localized stress concentrations and enhancing the overall resilience of the building. The damping characteristics of FRP also contribute to dissipating the energy generated by an earthquake, further safeguarding the structure against damage. However, it is important to note that the earthquake resistance of any structure depends on several factors, including the design, construction, and adherence to relevant building codes and regulations. Proper engineering analysis and design must be employed to ensure that the FRP pultrusion profiles are appropriately incorporated into the structure to withstand the expected seismic forces. In summary, while FRP pultrusion profiles offer certain advantages in earthquake resistance, their effectiveness in protecting against seismic events relies on proper design and construction practices. It is crucial to work with experienced professionals and follow established guidelines to ensure the optimal performance of FRP structures during earthquakes.

- Q: Are FRP pultrusion profiles resistant to ultraviolet radiation?

- Yes, FRP pultrusion profiles are generally resistant to ultraviolet radiation. The combination of the composite material and the resin used in pultrusion manufacturing provides excellent UV resistance, making them suitable for outdoor applications.

- Q: Can FRP pultrusion profiles be used in the construction of wastewater treatment tanks?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles can be effectively used in the construction of wastewater treatment tanks. FRP pultrusion profiles are known for their high strength-to-weight ratio, corrosion resistance, and durability, making them an ideal choice for applications in harsh environments such as wastewater treatment facilities. FRP pultrusion profiles are made by pulling continuous fibers, typically glass or carbon, through a resin bath and then through a heated die to form the desired shape. This process results in profiles with consistent cross-sections and excellent mechanical properties. In the construction of wastewater treatment tanks, FRP pultrusion profiles can be used for a variety of purposes. They can be employed as structural elements, such as beams, columns, and bracing systems, providing the necessary strength and stiffness to support the tank structure. FRP profiles can also be used as reinforcement in concrete structures, enhancing their durability and resistance to chemical attack from the wastewater. Furthermore, FRP pultrusion profiles can be designed to resist the corrosive effects of the chemicals and gases present in wastewater treatment tanks. Unlike traditional materials like steel or concrete, FRP is highly resistant to corrosion, ensuring a longer service life and reduced maintenance costs. Additionally, FRP profiles offer advantages in terms of installation and transportation. They are lightweight, allowing for easier handling and reduced labor requirements during construction. The modular nature of FRP profiles also facilitates quick assembly and disassembly, making maintenance and modifications more convenient. Overall, the use of FRP pultrusion profiles in the construction of wastewater treatment tanks provides numerous benefits, including high strength, corrosion resistance, durability, and ease of installation. These advantages make FRP a reliable and cost-effective choice for wastewater treatment facilities.

- Q: Can FRP pultrusion profiles be used in telecommunications applications?

- Telecommunications applications can utilize FRP pultrusion profiles, which offer a range of advantages that render them suitable for such infrastructure. To begin with, these profiles possess the desirable combination of being lightweight and strong, making them an excellent choice for supporting antennas, cable trays, and equipment racks. Their high strength-to-weight ratio enables easier installation and transportation while providing the necessary structural support. Moreover, FRP pultrusion profiles display corrosion resistance, a crucial characteristic for telecommunications applications. Given the exposure of telecommunications infrastructure to harsh environments like moisture, chemicals, and extreme temperatures, FRP's non-corrosive properties guarantee long-term durability and reliability, distinguishing it from traditional materials such as steel or wood. Additionally, FRP pultrusion profiles offer electrical insulation properties, which are vital in telecommunications applications. By not conducting electricity, they ensure safety in areas where electrical equipment is present. This feature prevents electrical interference and preserves the integrity of the telecommunications system. Furthermore, FRP pultrusion profiles can be customized to meet specific design requirements, as they can be manufactured in various shapes and sizes. This flexibility allows for the efficient design of telecommunications infrastructure, making FRP pultrusion profiles suitable for a wide range of applications within the industry. In conclusion, FRP pultrusion profiles prove to be well-suited for telecommunications applications due to their lightweight yet strong nature, corrosion resistance, electrical insulation properties, and customization possibilities. These attributes guarantee their reliability in supporting and protecting telecommunications infrastructure.

- Q: Can FRP pultrusion profiles be used in the mining and mineral processing industry?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles can be used in the mining and mineral processing industry. FRP pultrusion profiles have several properties that make them suitable for use in this industry. Firstly, FRP pultrusion profiles are lightweight yet incredibly strong. This makes them ideal for applications where weight reduction is important, such as in mining equipment or processing plants. Despite their lightweight nature, FRP profiles can withstand heavy loads and resist corrosion, which is particularly beneficial in the mining industry where equipment is exposed to harsh environments and corrosive substances. Secondly, FRP pultrusion profiles are non-conductive and possess excellent electrical insulation properties. This is advantageous in mining and mineral processing operations where electrical safety is paramount. FRP profiles can be used in applications where electrical conductivity needs to be avoided, such as in electrical enclosures or cable trays. Additionally, FRP pultrusion profiles are highly resistant to chemicals, including acids and alkalis. This makes them suitable for use in mineral processing plants where various corrosive chemicals are used in the extraction and processing of minerals. FRP profiles can withstand exposure to these chemicals without deteriorating or experiencing significant damage, prolonging their lifespan and reducing maintenance costs. Furthermore, FRP pultrusion profiles have a high strength-to-weight ratio, which means they can be used to create durable and lightweight structures. This is particularly beneficial in mining operations where structures such as walkways, ladders, and platforms need to be installed in challenging terrains. The lightweight nature of FRP profiles makes them easier to transport, handle, and install compared to traditional materials like steel. In conclusion, FRP pultrusion profiles can be effectively used in the mining and mineral processing industry due to their lightweight, high strength, corrosion resistance, electrical insulation, and chemical resistance properties. These profiles offer numerous advantages over traditional materials, making them a viable option for various applications in this industry.

- Q: Are FRP pultrusion profiles resistant to chemical spills or leaks?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles are highly resistant to chemical spills or leaks. The combination of the fiberglass reinforcement and the polymer matrix used in FRP pultrusion provides excellent resistance to a wide range of chemicals, acids, and corrosive substances. This makes FRP pultrusion profiles a suitable choice for applications where chemical resistance is crucial, such as in chemical processing plants, wastewater treatment facilities, and storage tanks.

Send your message to us

FRP Pultrusion Profiles - High Quality Supplier & Manufacturer

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords