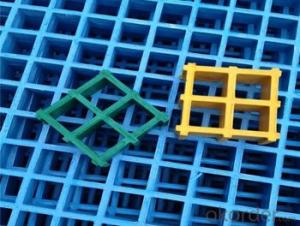

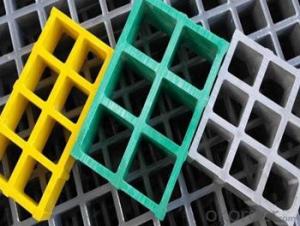

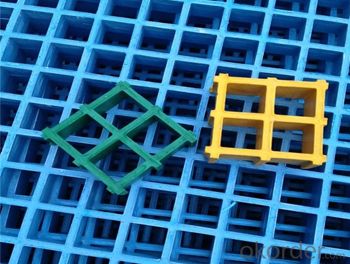

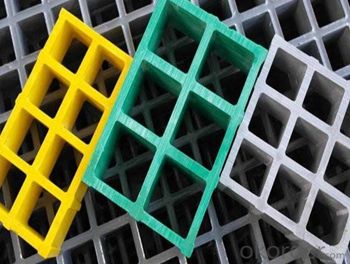

FRP pultruded grating with Light weight and high strength with noxic of different styles

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 13 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

PRODUCT DESCRIPTION

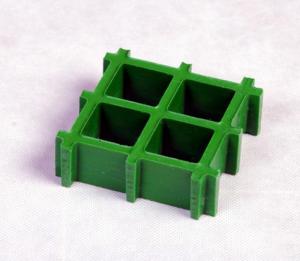

Pultruded grating is made by a particular assembly process, which using “I” shape as its main load-bearing and special rod to go through the bearing bar. Pultruded grating include the standard grating and the custom grating, the custom grating can be designed to meet customer’s requirement or special using condition by changing the shape, size and space of the bearing bars, the surface can be covered with lozenge panel, grit panel, or added the anti-slippery sand directly.

FRP pultruded grating has the most characteristics of molded grating, but it has its distinct advantages, it has very high fiberglass content in the loading direction, so it has very high load capability, it has more superiority when used at wide span, so that the basic support will be decreased and the project cost will be reduced accordingly.

SPECIFICATION

The standard space between two crossbars is 6 inch or 12 inch.

Thickness (mm) | Bar width (mm) | Open space (mm) | Open rate (%) | Approx weight (kg/m |

25.4 | 15.2 | 22.8 | 60 | 13.2 |

25.4 | 15.2 | 15.2 | 50 | 15.9 |

25.4 | 15.2 | 10.1 | 40 | 18.5 |

25.4 | 40 | 10.8 | 21 | 14.5 |

38.1 | 15.2 | 22.8 | 60 | 15.8 |

38.1 | 15.2 | 15.2 | 50 | 19.1 |

38.1 | 15.2 | 10.1 | 40 | 22.4 |

50.8 | 25.4 | 25.4 | 50 | 16.6 |

50.8 | 25.4 | 12.7 | 33 | 21.1 |

FEATURES

a. Anti-corrosion and anti-rust

b. Light weight and high strength

c. Anti-flammable

d. Anti- fatigue

e. Safe and anti-slippery

f. Anti-ageing

g. Easy of maintenance

h. Excellent electromagnetism property

i. Good economic benefit

FIELDS SERVED

Sewage treatment,

water supply and drainage,

chemical industry,

oil industry,

power engineering,

pulp and paper,

construction engineering,

spinning, marine engineering.

COMPANT DESCRIPTION

CNBM International Corporation is one subsidiary of CNBM, we focus on offering good-quality products,professional service and complete solution to our customers. Strong delivery capacity, advanced technology& management, strong financing capability and excellent after-sale service are our advantages in sharing international market.

FAQ

Q1.What's your sample policy?

A:We can supply the sample if we have ready parts in stock, but the customers have to pay the courier cost.

Q2.Can you produce according to the samples?

A: Yes, we can produce or modify the products according to your request.

Q3.How do you deliver the goods to my country?

A:We can provide international express, such as DHL, EMS, UPS, FedEx, etc. We select air freight and sea freight upon your requests. Quotations if without mentioning the shipping costs are shipping fee excluded.

Q4.How much does it cost to ship to my country?

A:When you goanna to place an order, please contact us, because different country has different freight.

Q5.How to get the catalogue?

A:please contact us and tell us what you are looking for.

PICTURES

- Q: Can FRP pultrusion profiles be used in the construction of outdoor signage?

- Certainly, outdoor signage can utilize FRP pultrusion profiles. These profiles possess remarkable qualities, including durability, strength, and the ability to withstand different environmental conditions, rendering them ideal for outdoor use. Typically, these profiles consist of a combination of fiberglass reinforcement and resin matrix, resulting in a lightweight yet robust material. Outdoor signage often confronts harsh weather conditions, such as rain, sun exposure, and temperature fluctuations. FRP pultrusion profiles exhibit excellent resistance to corrosion, UV rays, and moisture, ensuring that the signage retains its structural integrity and visual appeal over time. Moreover, FRP pultrusion profiles offer customization options to fulfill specific design requirements, offering flexibility in creating distinctive and captivating outdoor signage. These profiles can be effortlessly shaped, cut, and assembled, making them a versatile choice for signage applications. In essence, the construction of outdoor signage can undoubtedly benefit from the use of FRP pultrusion profiles due to their durability, resistance to environmental conditions, and design flexibility.

- Q: Can FRP pultrusion profiles be used in the construction of wind turbine blades?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles can be used in the construction of wind turbine blades. FRP pultrusion profiles offer several advantages that make them suitable for wind turbine blade construction. Firstly, FRP pultrusion profiles are lightweight yet strong, which is an important characteristic in wind turbine blades as they need to be able to withstand the aerodynamic forces exerted by the wind. The high strength-to-weight ratio of FRP pultrusion profiles allows for the construction of longer and more efficient blades. Additionally, FRP pultrusion profiles have excellent corrosion resistance properties, which is crucial for wind turbines exposed to harsh weather conditions. Unlike traditional materials like steel, FRP does not corrode, ensuring a longer service life for the wind turbine blades. Moreover, FRP pultrusion profiles can be customized to meet specific design requirements. This flexibility allows for the optimization of blade performance by tailoring the shape, thickness, and stiffness of the profiles to maximize energy capture and minimize fatigue. Furthermore, FRP pultrusion profiles offer good fatigue resistance, meaning they can withstand repeated loading cycles without experiencing significant degradation in performance. This is essential for wind turbine blades that are subjected to cyclic loading due to wind gusts and changes in wind direction. Finally, FRP pultrusion profiles are also electrically non-conductive, which is advantageous for wind turbine blades as it eliminates the risk of electrical discharge during operation. Overall, the lightweight, strong, corrosion-resistant, and customizable nature of FRP pultrusion profiles make them an excellent choice for the construction of wind turbine blades, contributing to the development of more efficient and durable wind energy systems.

- Q: What is the torsional strength of FRP pultrusion profiles?

- The torsional strength of FRP (Fiber Reinforced Polymer) pultrusion profiles is determined by various factors including the type and arrangement of fibers, resin matrix, manufacturing process, and the overall design of the profile. FRP pultrusion profiles are typically designed to have high torsional strength due to the inherent properties of the composite materials used. The torsional strength of FRP pultrusion profiles can vary depending on the specific application and the desired performance requirements. Manufacturers often conduct extensive testing to determine the torsional strength of their profiles and provide relevant data to customers. FRP pultrusion profiles are known for their excellent torsional strength compared to traditional materials like steel or aluminum. The combination of high-strength fibers and a durable resin matrix allows FRP profiles to withstand significant torsional forces without experiencing permanent deformation or failure. It is important to note that the torsional strength of FRP pultrusion profiles can be customized to meet specific project requirements. By adjusting the fiber type, fiber orientation, resin system, and profile geometry, manufacturers can optimize the torsional strength to ensure that the profiles can withstand the anticipated loads and operational conditions. In summary, the torsional strength of FRP pultrusion profiles is generally high due to the unique properties of the composite materials used and can be further customized to meet specific application requirements.

- Q: Are FRP pultrusion profiles resistant to fading or discoloration?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles are highly resistant to fading and discoloration. This is due to the inherent properties of the materials used in their construction. FRP profiles are typically made with a combination of fiberglass reinforcements and a polymer resin matrix, which are both inherently resistant to UV radiation and other environmental factors that cause fading and discoloration. The polymer resin matrix used in FRP profiles is specifically formulated to provide excellent chemical resistance and UV stability, ensuring that the profiles maintain their original color and appearance over an extended period of time. This makes FRP pultrusion profiles an ideal choice for outdoor applications, where exposure to sunlight and other harsh weather conditions is common. Furthermore, the manufacturing process of pultrusion ensures that the color of FRP profiles is consistent throughout their entire cross-section. This means that even if there is minor surface damage or wear, the underlying color of the profile remains the same, ensuring a consistent appearance. Overall, FRP pultrusion profiles offer superior resistance to fading and discoloration, making them a durable and long-lasting option for various applications, such as construction, infrastructure, transportation, and more.

- Q: What are the circumstances in which the pultrusion should be performed?

- (1) the tensile strength of high strength extruded profiles for 150 ~ 300MPa, the bending strength reached 200 ~ 300MPa, the 1000h accelerated the bending strength after aging the retention rate of up to 78%.(2) the deformation rate is low. The length of the glass reinforced plastic pultruded section is accelerated by 1000h and the width change rate is +0.03%. The width change rate is -0.07%.. Therefore, the geometry and size of the product made of this pultruded section can be stable for a long time

- Q: Are FRP pultrusion profiles resistant to chemicals used in oil refineries?

- FRP pultrusion profiles have a high resistance to chemicals utilized in oil refineries. These profiles consist of a combination of strong fibers (such as fiberglass, carbon fibers, or aramid fibers) embedded in a polymer resin matrix. This unique construction grants them exceptional resistance to various chemicals commonly found in oil refineries. The polymer resin matrix used in FRP profiles can be carefully chosen to withstand harsh chemical environments. For oil refinery applications, vinyl ester or epoxy resins are often employed due to their superior chemical resistance properties. Additionally, FRP pultrusion profiles are inherently corrosion-resistant, unlike traditional materials like steel or concrete that deteriorate when exposed to aggressive chemicals found in oil refineries. This corrosion resistance ensures the long-term durability and reliability of FRP profiles in such environments. Furthermore, FRP profiles offer several other advantages in oil refinery applications, including a high strength-to-weight ratio, electrical insulation, non-magnetic properties, and ease of installation. These characteristics make FRP pultrusion profiles an ideal choice for various structural, piping, and equipment applications within oil refineries. However, it is crucial to consider the specific chemicals and concentrations involved in a particular oil refinery application. While FRP profiles generally exhibit excellent resistance to a wide range of chemicals, there may be highly concentrated or specialized chemicals that could potentially impact their performance. In such cases, it is advisable to seek guidance from FRP manufacturers or experts who can offer tailored solutions to meet the specific chemical resistance requirements of the oil refinery.

- Q: Can FRP pultrusion profiles be used in the telecommunications and data communication industry?

- Yes, FRP (Fiber Reinforced Plastic) pultrusion profiles can be used in the telecommunications and data communication industry. FRP pultruded profiles have several advantages that make them suitable for use in this industry. Firstly, FRP pultrusion profiles offer excellent electrical insulation properties, making them ideal for applications in the telecommunications and data communication industry where electrical conductivity needs to be minimized. FRP profiles do not conduct electricity, ensuring that there are no interference or grounding issues that could disrupt the transmission of data. Secondly, FRP pultrusion profiles are lightweight yet strong, providing a high strength-to-weight ratio. This makes them suitable for use in the construction of communication towers, antenna supports, and satellite dish mountings, where the profiles need to withstand wind loads and other environmental stresses. Additionally, FRP profiles have excellent corrosion resistance, which is crucial in the telecommunications and data communication industry where equipment is often exposed to harsh outdoor environments. Unlike traditional materials such as steel or aluminum, FRP profiles do not rust or corrode, ensuring the longevity and reliability of the infrastructure. Furthermore, FRP profiles can be easily customized and manufactured in various shapes and sizes to meet the specific requirements of telecommunications and data communication applications. This flexibility allows for the design and construction of complex structures that can accommodate different equipment and technologies. Overall, FRP pultrusion profiles offer a range of benefits that make them well-suited for use in the telecommunications and data communication industry. Their electrical insulation properties, lightweight yet strong nature, corrosion resistance, and flexibility in design make them a reliable choice for supporting infrastructure in this sector.

- Q: Are FRP pultrusion profiles electrically conductive?

- Typically, FRP pultrusion profiles lack electrical conductivity due to the utilization of a blend of fiberglass reinforcement and a thermosetting resin matrix. These components offer exceptional insulation qualities. The inherent non-conductive nature of the fiberglass reinforcement is further amplified by the resin matrix. Consequently, FRP pultrusion profiles find frequent application in situations where electrical conductivity is undesirable or poses safety hazards. Nevertheless, it is noteworthy that specific modifications or additions can be implemented during the pultrusion process to introduce electrical conductivity, if needed for particular applications.

- Q: Are FRP pultrusion profiles suitable for the manufacturing of boat hulls?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles are suitable for the manufacturing of boat hulls. Their high strength-to-weight ratio, corrosion resistance, and durability make them an ideal choice for boat construction. Additionally, pultruded profiles can be customized to meet specific design requirements and offer excellent dimensional stability, making them a reliable option for boat hull manufacturing.

- Q: Are FRP pultrusion profiles resistant to oil or fuel spills?

- Yes, FRP pultrusion profiles have inherent resistance to oil and fuel spills. The combination of the fiberglass reinforcement and the resin matrix used in their construction make them highly resistant to the corrosive effects of oil and fuel, making them a suitable choice for applications where exposure to such spills is expected.

Send your message to us

FRP pultruded grating with Light weight and high strength with noxic of different styles

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 13 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords