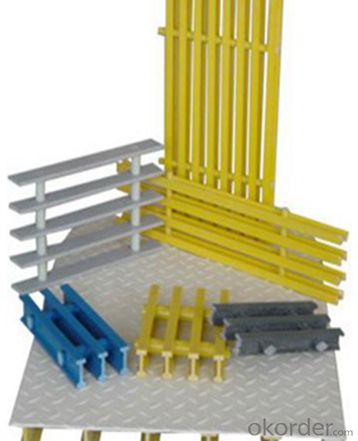

FRP Pultrusion Profiles - Pultruded Grating with Easy Maintenance and High Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

PRODUCT DESCRIPTION

Pultruded grating is made by a particular assembly process, which using “I” shape as its main load-bearing and special rod to go through the bearing bar. Pultruded grating include the standard grating and the custom grating, the custom grating can be designed to meet customer’s requirement or special using condition by changing the shape, size and space of the bearing bars, the surface can be covered with lozenge panel, grit panel, or added the anti-slippery sand directly.

SPECIFICATION

The standard space between two crossbars is 6 inch or 12 inch.

Thickness (mm) | Bar width (mm) | Open space (mm) | Open rate (%) | Approx weight (kg/m |

25.4 | 15.2 | 22.8 | 60 | 13.2 |

25.4 | 15.2 | 15.2 | 50 | 15.9 |

25.4 | 15.2 | 10.1 | 40 | 18.5 |

25.4 | 40 | 10.8 | 21 | 14.5 |

38.1 | 15.2 | 22.8 | 60 | 15.8 |

38.1 | 15.2 | 15.2 | 50 | 19.1 |

38.1 | 15.2 | 10.1 | 40 | 22.4 |

50.8 | 25.4 | 25.4 | 50 | 16.6 |

50.8 | 25.4 | 12.7 | 33 | 21.1 |

CHOICE FOR PULTRUDED GRATING

Resin: GP resin, ISO resin, VE resin, Phenol resin

Color choice: Yellow, gray, green, custom color

Surface choice: Groove surface, grit surface, lozenge cover surface

FEATURES

a. Anti-corrosion and anti-rust

b. Light weight and high strength

c. Anti-flammable

d. Anti- fatigue

e. Safe and anti-slippery

f. Anti-ageing

g. Easy of maintenance

h. Excellent electromagnetism property

i. Good economic benefit

FIELDS SERVED

Sewage treatment,

water supply and drainage,

chemical industry,

oil industry,

power engineering,

pulp and paper,

construction engineering,

spinning, marine engineering.

APPLICATION

Operation terrace,

stair walkway,

ground floor,

trench cover,

sidewalk,

foot bridge,

equipment safety fence,

scaffold.

COMPANT DESCRIPTION

CNBM,China National Building Materials Group is a state-owned enterprise in charge of administrative affairs in china building materials industry. Established in 1984, CNBM is a large group corporation of building materials with total assets of 25 billion RMB and a total staff of 30,000.CNBM now owns 200 subordinating firms of solely owned and joint-venture companies.

CNBM International Corporation is one subsidiary of CNBM, we focus on offering good-quality products,professional service and complete solution to our customers. Strong delivery capacity, advanced technology& management, strong financing capability and excellent after-sale service are our advantages in sharing international market.

FAQ

Q1.What's your sample policy?

A:We can supply the sample if we have ready parts in stock, but the customers have to pay the courier cost.

Q2.Can you produce according to the samples?

A: Yes, we can produce or modify the products according to your request.

Q3.How do you deliver the goods to my country?

A:We can provide international express, such as DHL, EMS, UPS, FedEx, etc. We select air freight and sea freight upon your requests. Quotations if without mentioning the shipping costs are shipping fee excluded.

Q4.How much does it cost to ship to my country?

A:When you goanna to place an order, please contact us, because different country has different freight.

Q5.How to get the catalogue?

A:please contact us and tell us what you are looking for.

We will try our best to meet customers' demands. Welcome you come here to visit us. We sincerely welcome partners around the world to establish business cooperation with us on the basis of mutual trust, benefit and development.

PICTURES

- Q: Are FRP pultrusion profiles resistant to hail or impact damage?

- FRP pultrusion profiles exhibit exceptional resistance to both hail and impact damage. The incorporation of reinforcing fibers such as carbon or glass, along with a polymer resin matrix, grants these profiles unparalleled strength and durability. When compared to materials like wood, steel, or aluminum, FRP pultrusions offer significantly superior impact resistance. These profiles are specifically engineered to endure even the harshest environmental conditions, including hailstorms. The composite composition of FRP enables it to effectively absorb and distribute the energy generated by impacts, effectively preventing the formation of cracks or fractures. As a result, they are an ideal choice for various applications that necessitate protection against hail or impact damage, such as building facades, bridges, handrails, and utility poles. Moreover, FRP pultrusion profiles possess an impressive strength-to-weight ratio, meaning they can withstand heavy impacts without undermining their structural integrity. Furthermore, they are non-corrosive, making them impervious to rust or degradation caused by hail or impact. To summarize, the composite construction and exceptional strength-to-weight ratio of FRP pultrusion profiles render them highly resistant to hail or impact damage. They offer a reliable and long-lasting solution for applications that demand durability and resilience in the face of harsh environmental conditions.

- Q: Are FRP pultrusion profiles resistant to high winds or hurricanes?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles are highly resistant to high winds and hurricanes. FRP is a composite material that combines the strength of fiberglass with the durability of polymers. This results in a lightweight yet incredibly strong material that can withstand extreme weather conditions. FRP pultrusion profiles have been extensively tested and have proven to have excellent wind resistance properties. They have a high stiffness-to-weight ratio, allowing them to withstand the forces exerted by high winds without bending or breaking. Additionally, the inherent flexibility of FRP allows it to absorb and distribute the forces exerted by wind, reducing the risk of damage. In the case of hurricanes, FRP pultrusion profiles have demonstrated their ability to withstand the strong winds and flying debris associated with these severe weather events. They have been used in various applications such as building facades, bridges, and utility poles in hurricane-prone areas, with great success. Furthermore, FRP pultrusion profiles are corrosion-resistant, which is another advantage when it comes to withstanding high winds and hurricanes. Unlike traditional materials like steel or wood, FRP profiles do not rust or rot when exposed to moisture, making them even more suitable for these challenging weather conditions. Overall, due to their high strength, durability, flexibility, and corrosion resistance, FRP pultrusion profiles are an excellent choice for applications where resistance to high winds or hurricanes is required.

- Q: Can FRP pultrusion profiles be used in agricultural applications?

- Yes, FRP pultrusion profiles can be used in agricultural applications. These profiles offer several advantages such as high strength, corrosion resistance, and durability, making them suitable for various agricultural structures and equipment. They can be used for applications like greenhouse structures, livestock housing, irrigation systems, and fencing, among others. Additionally, FRP profiles are lightweight and easy to install, making them a cost-effective choice for agricultural applications.

- Q: Can FRP pultrusion profiles be used in agricultural structures?

- Agricultural structures can indeed utilize FRP pultrusion profiles. FRP pultrusion profiles, also known as Fiber Reinforced Polymer profiles, possess numerous advantages that render them suitable for agricultural purposes. To begin with, the corrosion resistance of FRP profiles is of utmost importance in the agricultural industry, given the exposure of structures to harsh environments and chemicals like fertilizers and pesticides. Unlike conventional materials such as steel or wood, FRP does not rust or decay, ensuring enduring performance in agricultural structures. Furthermore, FRP profiles are lightweight yet durable, facilitating easy handling and installation in agricultural applications. Their high strength-to-weight ratios enable efficient construction, thereby reducing the necessity for heavy machinery during the installation process. Moreover, FRP profiles exhibit exceptional mechanical properties, including high stiffness and impact resistance, which prove advantageous for agricultural structures subjected to heavy loads, vibrations, or machinery impact. In addition, FRP pultrusion profiles can be designed to resist UV radiation, thereby preventing degradation from prolonged exposure to sunlight. This quality makes them suitable for outdoor agricultural structures consistently exposed to the elements. Lastly, FRP profiles are non-conductive, a critical advantage in agricultural environments where electrical safety is paramount. This characteristic eliminates the risk of electrical hazards associated with conductive materials like steel. In summary, FRP pultrusion profiles offer a reliable and efficient solution for a variety of agricultural structures, such as greenhouse frames, livestock enclosures, irrigation systems, and storage facilities. Their corrosion resistance, lightweight nature, high strength, UV resistance, and non-conductivity make them an ideal choice for agricultural applications.

- Q: How do FRP pultrusion profiles handle cyclic torsion loads?

- FRP (Fiber Reinforced Polymer) pultrusion profiles are designed to handle cyclic torsion loads effectively. The unique properties of FRP materials make them highly resistant to fatigue, making them suitable for applications where cyclic torsion loads are expected. One key advantage of FRP pultrusion profiles is their high strength-to-weight ratio. Reinforced with fibers such as glass or carbon, these profiles offer excellent tensile strength and stiffness, enabling them to withstand repeated torsional forces without deformation or failure. Moreover, FRP pultrusion profiles exhibit superior resistance to corrosion and chemical degradation compared to traditional materials like steel. This resistance ensures that the profiles maintain their structural integrity even in harsh environments where cyclic torsion loads may be prevalent. The manufacturing process of pultrusion also contributes to the ability of FRP profiles to handle cyclic torsion loads. During pultrusion, continuous fibers are impregnated with a polymer resin and then pulled through a heated die, where they are cured and shaped into the desired profile. This process ensures a uniform distribution of fibers throughout the profile, resulting in enhanced strength and stiffness in all directions, including torsion. To further enhance the performance of FRP pultrusion profiles under cyclic torsion loads, engineers employ design techniques such as optimizing the fiber orientation and selecting appropriate resin systems. These measures help distribute the torsional forces evenly across the profile, minimizing stress concentrations and improving the fatigue resistance. In summary, FRP pultrusion profiles are specifically engineered to handle cyclic torsion loads. Their high strength-to-weight ratio, resistance to corrosion, and uniform fiber distribution make them an ideal choice for applications where cyclic torsion loads are a concern.

- Q: Are FRP pultrusion profiles resistant to caustic soda?

- FRP pultrusion profiles are generally immune to caustic soda, which is a potent alkaline substance capable of corroding certain materials. However, FRP pultrusion profiles consist of robust fibers (like fiberglass) combined with a resin matrix (such as polyester or epoxy). This composite construction renders them highly resistant to chemicals, including caustic soda. Consequently, FRP pultrusion profiles find extensive application in industries prone to exposure to corrosive substances, such as chemical processing, wastewater treatment, and mining. It is worth noting that the choice of resin in the FRP profiles, along with the concentration and temperature of the caustic soda, can impact the overall level of resistance.

- Q: How do FRP pultrusion profiles handle compression loads?

- FRP (Fiber-Reinforced Polymer) pultrusion profiles handle compression loads in a unique and effective way due to their structure and material composition. Pultruded profiles are made by pulling continuous fibers, such as glass or carbon, through a resin bath and then through a heated die, where the resin is cured and the shape is formed. When it comes to compression loads, FRP pultrusion profiles exhibit excellent performance. The continuous fibers embedded within the resin matrix make the profiles highly stiff and strong, allowing them to effectively resist compressive forces. The fibers distribute the load evenly along the length of the profile, preventing localized failure and ensuring overall structural integrity. The fiber reinforcement in FRP pultrusion profiles also provides excellent resistance against buckling. Buckling is a phenomenon where a slender structural member fails due to excessive compressive loads causing instability. The high strength-to-weight ratio of the fibers helps prevent buckling and allows the profiles to withstand substantial compression forces without compromising their structural integrity. Additionally, the resin matrix in FRP pultrusion profiles plays a crucial role in handling compression loads. The resin provides a protective layer around the fibers, preventing them from being damaged or fractured under compressive forces. It also acts as a load transfer medium, distributing the compressive load to the fibers, which then carry the load throughout the entire profile. Overall, FRP pultrusion profiles are well-suited for handling compression loads due to their fiber reinforcement and resin matrix. They offer high strength, stiffness, and resistance to buckling, making them an ideal choice for a wide range of applications where compression loads are a concern.

- Q: Are FRP pultrusion profiles UV resistant?

- FRP pultrusion profiles are known for their UV resistance. This is because manufacturers use a combination of polymer resin and reinforced fibers, like fiberglass, to create these profiles. These materials naturally possess UV resistant properties, which means that FRP pultrusion profiles can withstand prolonged exposure to sunlight and ultraviolet radiation without getting damaged. For outdoor applications, such as in construction, infrastructure, and marine industries, UV resistance is an important characteristic. However, it's worth noting that the level of UV resistance can vary depending on the specific resin and fiber composition used in the manufacturing process. To get precise information about the UV resistance of FRP pultrusion profiles for a specific application, it's advisable to consult the manufacturer or supplier.

- Q: Can FRP pultrusion profiles be used in the construction of playground equipment?

- FRP pultrusion profiles are indeed applicable in the construction of playground equipment. Renowned for their exceptional strength-to-weight ratio, resistance to corrosion, and long-lasting quality, these profiles prove to be ideal for outdoor applications like playground equipment. The versatility of these profiles allows for the creation of various structures such as slides, climbing frames, and play structures. Moreover, the ability to mold FRP pultrusion profiles into different shapes and sizes provides flexibility in design and customization options for playground equipment. An added advantage is that FRP materials are non-conductive, ensuring the safety of children. All in all, the numerous benefits offered by FRP pultrusion profiles make them an appropriate choice for constructing playground equipment.

- Q: Can FRP pultrusion profiles be used in the oil and gas industry?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles can be used in the oil and gas industry. These profiles offer excellent corrosion resistance, high strength-to-weight ratio, and low maintenance requirements, making them suitable for various applications in the industry such as pipe supports, cable trays, handrails, and platforms. Additionally, FRP pultrusion profiles are non-conductive, non-magnetic, and possess good fire-retardant properties, making them a safer alternative to traditional materials in hazardous environments.

Send your message to us

FRP Pultrusion Profiles - Pultruded Grating with Easy Maintenance and High Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords