FRP Pultrusion Profiles - Pultruded Grating with Anti-Flammable and Latest Styles

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

PRODUCT DESCRIPTION

FRP pultruded grating has the most characteristics of molded grating, but it has its distinct advantages, it has very high fiberglass content in the loading direction, so it has very high load capability, it has more superiority when used at wide span, so that the basic support will be decreased and the project cost will be reduced accordingly.

SPECIFICATION

Thickness (mm) | Bar width (mm) | Open space (mm) | Open rate (%) | Approx weight (kg/m |

25.4 | 15.2 | 22.8 | 60 | 13.2 |

25.4 | 15.2 | 15.2 | 50 | 15.9 |

25.4 | 15.2 | 10.1 | 40 | 18.5 |

25.4 | 40 | 10.8 | 21 | 14.5 |

38.1 | 15.2 | 22.8 | 60 | 15.8 |

38.1 | 15.2 | 15.2 | 50 | 19.1 |

38.1 | 15.2 | 10.1 | 40 | 22.4 |

50.8 | 25.4 | 25.4 | 50 | 16.6 |

50.8 | 25.4 | 12.7 | 33 | 21.1 |

CHOICE FOR PULTRUDED GRATING

Resin: GP resin, ISO resin, VE resin, Phenol resin

Color choice: Yellow, gray, green, custom color

Surface choice: Groove surface, grit surface, lozenge cover surface

FEATURES

a. Anti-corrosion and anti-rust

b. Light weight and high strength

c. Anti-flammable

d. Anti- fatigue

e. Safe and anti-slippery

f. Anti-ageing

g. Easy of maintenance

FIELDS SERVED

Sewage treatment,

water supply and drainage,

chemical industry,

oil industry.

APPLICATION

Operation terrace,

stair walkway,

ground floor,

trench cover,

sidewalk,

foot bridge,

equipment safety fence,

scaffold.

COMPANT DESCRIPTION

CNBM,China National Building Materials Group is a state-owned enterprise in charge of administrative affairs in china building materials industry. Established in 1984, CNBM is a large group corporation of building materials with total assets of 25 billion RMB and a total staff of 30,000.CNBM now owns 200 subordinating firms of solely owned and joint-venture companies.

CNBM International Corporation is one subsidiary of CNBM, we focus on offering good-quality products,professional service and complete solution to our customers. Strong delivery capacity, advanced technology& management, strong financing capability and excellent after-sale service are our advantages in sharing international market.

FAQ

1.Q:Are you factory or trading company ?

A:We are Factory produce FRP machines and FRP products.

2.Q:If can customized by customers requirements?

A:yes,we can produce the machine with customized size.

3.Q:How about the payment?

A:We accept any kind of payment.

4.Q:What is the guarantee?

A:Gurantee is one year.

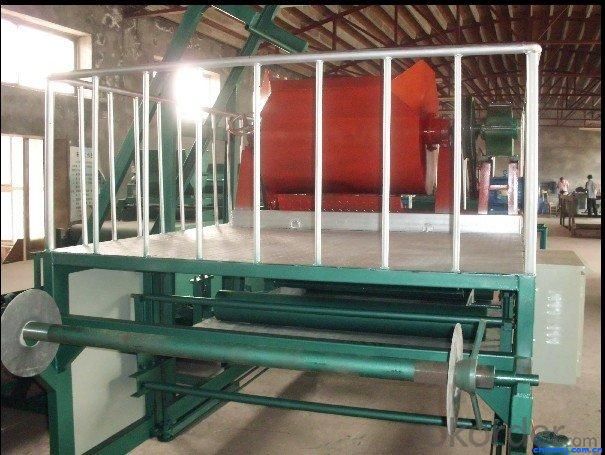

PICTURES

- Q: Can FRP pultrusion profiles be used for structural applications?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles can definitely be used for structural applications. Pultrusion is a manufacturing process that creates continuous, reinforced profiles by pulling fiber reinforcements through a resin bath and then through a heated die to cure the resin. This process results in strong, lightweight, and corrosion-resistant profiles that have excellent mechanical properties. FRP pultrusion profiles are widely used in various structural applications due to their high strength-to-weight ratio. These profiles can be engineered to have specific load-bearing capacities, stiffness, and durability, making them suitable for a range of structural requirements. Some common structural applications for FRP pultrusion profiles include bridges, walkways, platforms, handrails, supports, beams, columns, and reinforcements in concrete structures. They are also used in applications where traditional materials like steel or wood are not suitable due to corrosion, electrical conductivity, or weight concerns. FRP pultrusion profiles offer several advantages over traditional materials. They are lightweight, which makes them easier to handle and transport. Additionally, they are resistant to corrosion, chemicals, and UV radiation, providing long-term durability even in harsh environments. Moreover, they have excellent dimensional stability, meaning they do not warp, twist, or shrink over time. In conclusion, FRP pultrusion profiles are highly suitable for structural applications due to their strength, lightweight nature, corrosion resistance, and durability. They offer a cost-effective alternative to traditional materials while providing superior performance in various structural projects.

- Q: How do FRP pultrusion profiles perform in extreme temperatures?

- FRP pultrusion profiles are known for their excellent performance in extreme temperatures. Due to their unique composition of fiberglass and resin matrix, they are highly resistant to thermal expansion and contraction. This means that even in extremely cold or hot environments, FRP profiles maintain their structural integrity without warping or deforming. In high-temperature conditions, FRP pultrusion profiles exhibit remarkable dimensional stability and do not soften or melt like some other materials. They have a high glass transition temperature, which allows them to withstand even the most extreme heat without losing their strength or shape. This makes FRP profiles suitable for applications such as furnace components, exhaust systems, and industrial ovens. On the other hand, in extremely cold temperatures, FRP pultrusion profiles remain tough and durable. They do not become brittle or prone to cracking like traditional materials such as metal or concrete. This makes them suitable for use in cold storage facilities, refrigerated trucks, and other low-temperature environments. Furthermore, FRP pultrusion profiles have excellent resistance to chemical corrosion. They are not affected by exposure to various chemicals or solvents, making them suitable for use in harsh chemical processing environments. This resistance to chemical corrosion also extends to extreme temperatures, further enhancing their performance in such conditions. Overall, FRP pultrusion profiles have proven to be reliable and versatile materials in extreme temperature environments. Their ability to maintain structural integrity, dimensional stability, and resistance to chemical corrosion make them a preferred choice for various industries and applications where temperature extremes are a concern.

- Q: Can FRP pultrusion profiles be used in the construction of pedestrian tunnels?

- Pedestrian tunnels can utilize FRP (Fiber Reinforced Polymer) pultrusion profiles. FRP is a lightweight and high-strength material that presents several advantages over traditional construction materials like steel or concrete. Corrosion resistance is a significant benefit of FRP pultrusion profiles in pedestrian tunnel construction. Unlike steel, FRP does not corrode when exposed to moisture or harsh environmental conditions. This is particularly valuable for underground structures like pedestrian tunnels, where water seepage or high humidity may pose concerns. Moreover, FRP pultrusion profiles possess exceptional mechanical properties, including high tensile strength and stiffness. Consequently, they can endure heavy loads and provide structural integrity to the tunnel. FRP's lightweight characteristic also simplifies handling and installation, ultimately reducing construction time and costs. Additionally, FRP profiles can be easily molded into various shapes and sizes, making them highly versatile for designing pedestrian tunnels. They can be tailored to meet specific project requirements, such as tunnel curvature or dimensions. This design flexibility enables innovative and efficient solutions in tunnel construction. Regarding safety, FRP pultrusion profiles exhibit high fire resistance and are non-conductive, crucial for ensuring pedestrian safety in tunnels. They also possess low thermal conductivity, providing insulation properties that help maintain a comfortable environment inside the tunnel. Overall, the utilization of FRP pultrusion profiles in pedestrian tunnel construction offers numerous benefits, including corrosion resistance, high strength, design versatility, and enhanced safety. These advantages establish FRP as an excellent choice for constructing durable and efficient pedestrian tunnels.

- Q: Are FRP pultrusion profiles resistant to chemicals used in agricultural applications?

- FRP pultrusion profiles are known for their exceptional resistance to chemicals commonly found in agricultural settings. These profiles are composed of reinforced fibers and a polymer resin matrix, typically polyester or vinyl ester, which provide outstanding protection against a wide range of agricultural chemicals, including fertilizers, pesticides, herbicides, and acids. The inherent corrosion resistance of FRP pultrusion profiles makes them highly sought-after in agricultural applications where exposure to chemicals is prevalent. Unlike traditional materials like wood, steel, or concrete, these profiles do not deteriorate or degrade when exposed to aggressive chemicals. This resistance ensures that the profiles remain structurally sound and perform effectively throughout their long lifespan, even in harsh agricultural conditions. Additionally, FRP pultrusion profiles excel in their resistance to corrosion, moisture, UV radiation, and temperature fluctuations. This durability makes them ideal for a variety of agricultural applications, such as structural supports, fencing, grating, decking, and irrigation systems. However, it is important to note that while FRP pultrusion profiles are highly resistant to chemicals, they may still experience some level of degradation or staining when exposed to extremely concentrated or highly aggressive chemicals. To ensure compatibility with the chosen FRP pultrusion profiles, it is recommended to consult with the manufacturer or supplier regarding the specific chemicals used in the agricultural application.

- Q: Are FRP pultrusion profiles resistant to mold and mildew?

- Yes, FRP pultrusion profiles are highly resistant to mold and mildew. The non-porous nature of the fiberglass reinforcement and the synthetic resin matrix used in pultrusion manufacturing make these profiles highly resistant to moisture absorption, preventing the growth of mold and mildew.

- Q: Can FRP pultrusion profiles be used in the construction of water slides?

- Yes, FRP pultrusion profiles can be used in the construction of water slides. FRP, or fiberglass reinforced plastic, offers excellent strength, durability, and corrosion resistance, making it a suitable material for water slide components. The pultrusion process allows for the production of customized profiles with specific shapes and dimensions, ensuring compatibility with water slide design requirements. Additionally, FRP's lightweight nature simplifies installation and maintenance while providing a safe and enjoyable experience for water slide users.

- Q: Are FRP pultrusion profiles resistant to chemicals used in food processing?

- Yes, FRP (Fiber Reinforced Plastic) pultrusion profiles are highly resistant to chemicals used in food processing. They are specifically engineered to withstand harsh chemical environments, including the cleaning and sterilization agents commonly used in food processing facilities. This resistance makes FRP pultrusion profiles a suitable material choice for various applications in the food industry where chemical resistance is crucial.

- Q: Can FRP pultrusion profiles be used in the production of electrical insulators?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles can be used in the production of electrical insulators. FRP pultrusion profiles are known for their excellent electrical insulation properties, making them suitable for a wide range of electrical applications. The high-strength and non-conductive nature of FRP materials make them ideal for insulating components in electrical systems, including insulators. FRP pultrusion profiles are made by impregnating continuous fibers, such as fiberglass, carbon fiber, or aramid, with a polymer resin, which is then cured and shaped using the pultrusion process. This results in a durable and lightweight material that offers excellent electrical insulation properties. Electrical insulators are used to prevent the flow of electric current between conductive materials or components. They are essential in electrical systems to maintain safety and prevent electrical leakage or short circuits. FRP pultrusion profiles can be designed and manufactured to meet the specific requirements of electrical insulators, including dimensional accuracy, mechanical strength, and electrical insulation performance. Additionally, FRP pultrusion profiles offer several advantages over traditional materials like wood, porcelain, or ceramics. They are corrosion-resistant, have a high strength-to-weight ratio, and can be easily customized to meet the specific needs of electrical insulator applications. FRP pultrusion profiles are also non-conductive, which is a crucial factor for electrical insulation. Overall, FRP pultrusion profiles are highly suitable for the production of electrical insulators due to their excellent electrical insulation properties, durability, lightweight, and customization options.

- Q: Are FRP pultrusion profiles resistant to fuels?

- Generally, FRP pultrusion profiles possess resistance to fuels. The combination of strong fibers and a polymer matrix grants FRP profiles significant resistance to a range of chemicals, including fuels. This resistance primarily stems from the non-reactive nature of the polymer matrix, which prevents fuel from causing notable degradation or harm to the profiles. Industries that frequently encounter fuel exposure, such as automotive, aerospace, and oil and gas sectors, commonly employ FRP pultrusion profiles. These profiles have undergone extensive testing and have demonstrated their ability to withstand prolonged contact with fuels without suffering detrimental effects. Furthermore, FRP profiles provide numerous advantages over traditional materials like steel or aluminum in applications involving fuels. They resist corrosion, are lightweight, and exhibit excellent dimensional stability, making them ideal for environments with a high risk of fuel exposure. However, it is important to note that the specific resistance of FRP pultrusion profiles to fuels may vary depending on the fuel type, concentration, and the composition of the FRP material itself. Therefore, it is always advisable to consult the manufacturer or supplier to ensure that the chosen FRP profiles are suitable for the particular fuel-related application.

- Q: Do FRP pultrusion profiles require any special tools for installation?

- Installation of FRP pultrusion profiles necessitates the use of specialized tools. These profiles are manufactured through a continuous process wherein fibers are drawn through a resin bath and subsequently into a heated die, resulting in a material that is not only strong and lightweight but also resistant to corrosion. To ensure the proper installation of FRP pultrusion profiles, various specific tools are commonly employed. These tools encompass: 1. Cutting Tools: During installation, it may be necessary to cut FRP profiles to specific lengths. To achieve clean and precise cuts, specialized cutting tools like high-speed saws or abrasive wheels are frequently utilized. 2. Drilling Tools: For the insertion of fasteners or other fittings, it might be necessary to drill holes in FRP profiles. To prevent damage to the profile while creating these holes, special drill bits designed for working with composite materials are typically employed. 3. Fastening Tools: Depending on the application, it may be necessary to fasten FRP profiles to other surfaces or structures. Commonly used fasteners include stainless steel screws, bolts, or adhesives, which are specifically chosen for their ability to securely hold the profiles in place. 4. Joining Tools: In certain instances, it may be necessary to join FRP profiles together in order to create longer lengths or more intricate shapes. To ensure a robust and secure connection, special joining techniques such as bonding, riveting, or the use of mechanical connectors are employed. It should be noted that the specific tools required for installation may vary depending on factors such as the complexity and size of the project, as well as the recommendations provided by the manufacturer. Therefore, it is always advisable to consult the manufacturer's installation guidelines or seek professional assistance to ensure the proper installation and optimal performance of FRP pultrusion profiles.

Send your message to us

FRP Pultrusion Profiles - Pultruded Grating with Anti-Flammable and Latest Styles

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords