FRP Pultrusion Profiles - FRP Pultruded Grating with Anti-Corrosion, Anti-Rust, and Best Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

PRODUCT DESCRIPTION

Pultruded grating is made by a particular assembly process, which using “I” shape as its main load-bearing and special rod to go through the bearing bar. Pultruded grating include the standard grating and the custom grating, the custom grating can be designed to meet customer’s requirement or special using condition by changing the shape, size and space of the bearing bars, the surface can be covered with lozenge panel, grit panel, or added the anti-slippery sand directly.

FRP pultruded grating has the most characteristics of molded grating, but it has its distinct advantages, it has very high fiberglass content in the loading direction, so it has very high load capability, it has more superiority when used at wide span, so that the basic support will be decreased and the project cost will be reduced accordingly.

SPECIFICATION

Thickness (mm) | Bar width (mm) | Open space (mm) | Open rate (%) | Approx weight (kg/m |

25.4 | 15.2 | 22.8 | 60 | 13.2 |

25.4 | 15.2 | 15.2 | 50 | 15.9 |

25.4 | 15.2 | 10.1 | 40 | 18.5 |

25.4 | 40 | 10.8 | 21 | 14.5 |

38.1 | 15.2 | 22.8 | 60 | 15.8 |

38.1 | 15.2 | 15.2 | 50 | 19.1 |

38.1 | 15.2 | 10.1 | 40 | 22.4 |

50.8 | 25.4 | 25.4 | 50 | 16.6 |

50.8 | 25.4 | 12.7 | 33 | 21.1 |

CHOICE FOR PULTRUDED GRATING

Resin: GP resin, ISO resin, VE resin, Phenol resin

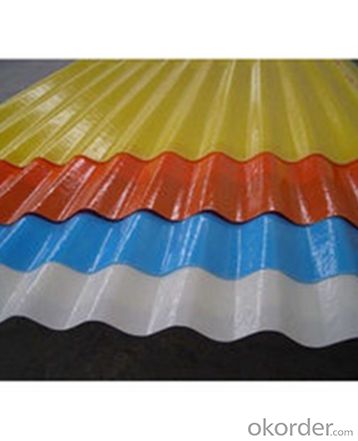

Color choice: Yellow, gray, green, custom color

Surface choice: Groove surface, grit surface, lozenge cover surface

FEATURES

a. Anti-corrosion and anti-rust

b. Light weight and high strength

c. Anti-flammable

d. Anti- fatigue

e. Safe and anti-slippery

f. . Good economic benefit

g. Easy of maintenance

h. Excellent electromagnetism property

FIELDS SERVED

Sewage treatment,

water supply and drainage,

chemical industry,

oil industry,

power engineering,

pulp and paper,

construction engineering,

spinning, marine engineering.

APPLICATION

Operation terrace,

stair walkway,

ground floor,

trench cover,

sidewalk,

foot bridge,

equipment safety fence,

scaffold.

COMPANT DESCRIPTION

CNBM,China National Building Materials Group is a state-owned enterprise in charge of administrative affairs in china building materials industry. Established in 1984, CNBM is a large group corporation of building materials with total assets of 25 billion RMB and a total staff of 30,000.CNBM now owns 200 subordinating firms of solely owned and joint-venture companies.

CNBM International Corporation is one subsidiary of CNBM, we focus on offering good-quality products,professional service and complete solution to our customers. Strong delivery capacity, advanced technology& management, strong financing capability and excellent after-sale service are our advantages in sharing international market.

FAQ

1.Q:Are you factory or trading company ?

A:We are Factory produce FRP machines and FRP products.

2.Q:If can customized by customers requirements?

A:yes,we can produce the machine with customized size.

3.Q:How about the payment?

A:We accept any kind of payment.

4.Q:What is the guarantee?

A:Gurantee is one year.

5.Q:If you can training?

A:yes ,we can training in our factory also can send engineers to your factory training.

PICTURES

- Q: Can FRP pultrusion profiles be used in the automotive industry?

- Certainly, the automotive industry can certainly make use of FRP (Fiber Reinforced Plastic) pultrusion profiles. These profiles possess several advantages that render them appropriate for automotive purposes. To begin with, FRP pultrusion profiles are lightweight, a critical factor in the automotive industry as it contributes to better fuel efficiency and reduced vehicle weight. Vehicles that are lighter consume less energy and emit fewer pollutants, making them more eco-friendly. Moreover, FRP pultrusion profiles exhibit a remarkable strength-to-weight ratio, enabling them to provide high strength and stiffness while remaining lightweight. This characteristic makes them ideal for structural components in automobiles, such as chassis, body panels, and support structures. In addition, FRP pultrusion profiles display exceptional corrosion resistance, a considerable advantage in automotive applications. Vehicles are frequently exposed to harsh environmental conditions, including moisture, salt, and chemicals. The corrosion resistance of FRP ensures the durability and longevity of automotive components, even in challenging environments. Furthermore, FRP pultrusion profiles possess impressive impact resistance, a crucial aspect of automotive safety. They can effectively absorb and dissipate energy during impacts, reducing the risk of injury in the event of accidents. Moreover, FRP pultrusion profiles can be customized and engineered to meet specific design requirements, allowing for versatility in automotive applications. They can be tailored to possess specific mechanical properties, shapes, and sizes, making them suitable for various automotive components. Overall, the combination of lightweight construction, high strength, corrosion resistance, impact resistance, and customization options make FRP pultrusion profiles an excellent choice for the automotive industry. They offer numerous benefits, including improved fuel efficiency, enhanced safety, and extended component life, making them a viable alternative to traditional materials in automotive applications.

- Q: What is the flexural strength of FRP pultrusion profiles?

- The flexural strength of FRP (Fiber Reinforced Polymer) pultrusion profiles varies depending on the specific composite materials used and the manufacturing process. FRP pultrusion profiles are engineered to have high strength-to-weight ratios and can typically exhibit flexural strengths ranging from around 300 MPa (43,500 psi) to over 1,000 MPa (145,000 psi). The flexural strength of FRP pultrusion profiles is influenced by factors such as the type and orientation of fibers, the resin matrix, the manufacturing technique, and any additional reinforcement or additives. For example, carbon fibers generally provide higher flexural strengths compared to glass fibers due to their inherent stiffness and strength properties. It is important to note that the flexural strength may vary based on the specific application and design requirements. Engineers and manufacturers typically conduct testing and analysis to determine the flexural strength properties of FRP pultrusion profiles for their intended use, ensuring compliance with safety standards and considering factors such as load requirements, environmental conditions, and service life expectations.

- Q: Are FRP pultrusion profiles resistant to automotive fluids?

- FRP pultrusion profiles, commonly known as Fiber Reinforced Polymer profiles, possess a general resistance to automotive fluids. FRP, an abbreviation for Fiber Reinforced Polymer, is a composite material comprising a combination of fibers and a polymer matrix. The fibers utilized in FRP, such as fiberglass, carbon, or aramid, exhibit exceptional resistance to various automotive fluids, including oils, fuels, and coolants. The polymer matrix found in FRP profiles usually consists of a thermosetting resin, namely polyester, vinyl ester, or epoxy. These resins are renowned for their chemical resistance properties, which contribute to the high resistance of FRP pultrusion profiles towards a wide array of automotive fluids. They can endure exposure to different fluids without significant deterioration or loss of mechanical properties. It is important to acknowledge that the specific resistance of FRP pultrusion profiles to automotive fluids may differ based on the resin type and the composite material's precise composition. As a result, it is advisable to consult the manufacturer or supplier of the FRP profiles to verify their suitability for the intended application and the specific automotive fluids they may encounter.

- Q: Are FRP Pultruded Shapes poisonous?

- The products certified by SGS are basically reliable.If the food is best to use food grade resin, there is a health permit.

- Q: Can FRP pultrusion profiles be used in the construction of swimming pool enclosures?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles can be used in the construction of swimming pool enclosures. FRP pultrusion profiles are known for their excellent strength-to-weight ratio, corrosion resistance, and durability, making them an ideal choice for outdoor applications like swimming pool enclosures. FRP pultrusion profiles are made by pulling fiberglass rovings through a resin bath and then through a heated die, resulting in a continuous profile of uniform shape and strength. This manufacturing process ensures that the profiles are strong, stiff, and lightweight, making them easy to handle and install. In the construction of swimming pool enclosures, FRP pultrusion profiles can be used for various structural elements such as beams, columns, trusses, and panels. These profiles can provide the necessary strength and support while also offering resistance to corrosion, moisture, and UV radiation, which are common challenges in a swimming pool environment. Additionally, FRP pultrusion profiles can be customized to meet specific design requirements, allowing for flexibility in creating unique and aesthetically pleasing swimming pool enclosures. They can be fabricated in a variety of shapes, sizes, and colors, making it possible to achieve the desired architectural look and feel. Overall, FRP pultrusion profiles offer a reliable and long-lasting solution for constructing swimming pool enclosures, providing the necessary strength, durability, and resistance to environmental factors. Their lightweight nature also makes them easier to handle and install, reducing construction time and costs.

- Q: Are FRP pultrusion profiles resistant to high-pressure water jets?

- Yes, FRP pultrusion profiles are generally resistant to high-pressure water jets due to their inherent corrosion resistance and ability to withstand harsh environmental conditions.

- Q: Are FRP pultrusion profiles resistant to fungal growth?

- Yes, FRP pultrusion profiles are highly resistant to fungal growth. The composite materials used in FRP pultrusion, such as fiberglass and resin, do not provide a suitable environment for fungi to grow. Additionally, the smooth surface of FRP profiles makes it difficult for fungi to attach and thrive. Hence, FRP pultrusion profiles are an excellent choice for applications where resistance to fungal growth is required.

- Q: Can FRP pultrusion profiles be used in the construction of outdoor signage?

- Certainly, outdoor signage can utilize FRP pultrusion profiles. These profiles possess remarkable qualities, including durability, strength, and the ability to withstand different environmental conditions, rendering them ideal for outdoor use. Typically, these profiles consist of a combination of fiberglass reinforcement and resin matrix, resulting in a lightweight yet robust material. Outdoor signage often confronts harsh weather conditions, such as rain, sun exposure, and temperature fluctuations. FRP pultrusion profiles exhibit excellent resistance to corrosion, UV rays, and moisture, ensuring that the signage retains its structural integrity and visual appeal over time. Moreover, FRP pultrusion profiles offer customization options to fulfill specific design requirements, offering flexibility in creating distinctive and captivating outdoor signage. These profiles can be effortlessly shaped, cut, and assembled, making them a versatile choice for signage applications. In essence, the construction of outdoor signage can undoubtedly benefit from the use of FRP pultrusion profiles due to their durability, resistance to environmental conditions, and design flexibility.

- Q: What types of materials are commonly used in FRP pultrusion?

- Commonly used materials in FRP pultrusion include fiberglass, polyester resin, vinyl ester resin, epoxy resin, carbon fiber, and aramid fiber.

- Q: Are FRP pultrusion profiles suitable for the manufacturing of chemical reactors?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles are suitable for the manufacturing of chemical reactors. FRP pultrusion profiles offer several advantages that make them well-suited for this application. Firstly, FRP pultrusion profiles are highly corrosion-resistant, which is a critical characteristic for chemical reactors that are exposed to harsh chemicals. Unlike traditional materials like steel or concrete, FRP does not corrode or degrade when exposed to a wide range of chemicals, making it a reliable choice for chemical reactor construction. Secondly, FRP pultrusion profiles are lightweight yet strong, providing excellent structural integrity and durability. This allows for the construction of large-scale chemical reactors without adding excessive weight, reducing installation and transportation costs. Furthermore, FRP pultrusion profiles offer design flexibility, allowing for customization to meet specific requirements. They can be easily molded into various shapes and sizes, enabling the construction of complex reactor designs that optimize efficiency and performance. In addition, FRP pultrusion profiles have excellent thermal insulation properties, which can be advantageous in maintaining stable operating temperatures within chemical reactors. This can help improve the overall energy efficiency of the reactor and reduce heat loss. Overall, FRP pultrusion profiles are suitable for the manufacturing of chemical reactors due to their corrosion resistance, lightweight yet strong nature, design flexibility, and thermal insulation properties. These profiles offer a reliable and cost-effective solution for constructing chemical reactors that can withstand the demanding conditions of chemical processing.

Send your message to us

FRP Pultrusion Profiles - FRP Pultruded Grating with Anti-Corrosion, Anti-Rust, and Best Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords