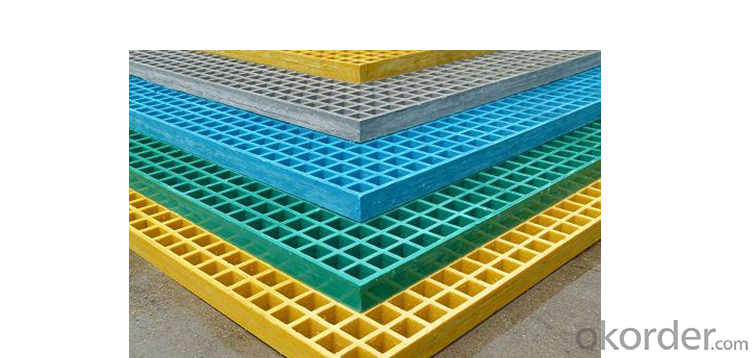

FRP Pultrusion Profiles Molded Gratings - Fiberglass & Plastic Grating Floors in Various Colors with Best Quality

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 5000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction

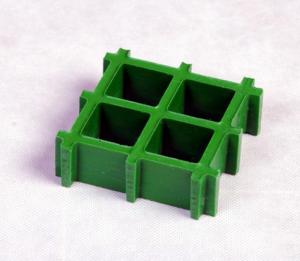

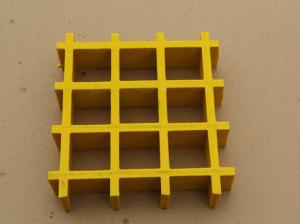

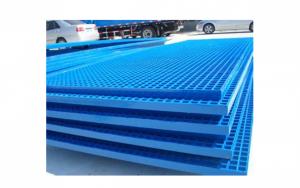

FRP Molded Grating is a structural panel which uses high-strength E-Glass roving as reinforcing material, thermosetting resin as matrix and then casted and formed in a special metal mold. It provides properties of light weight, high strength, corrosion resistance, fire resistance and anti-skid. FRP Molded Grating is widely used in oil industry, power engineering, water & waste water treatment, ocean survey as working floor, stair tread, trench cover, etc. and is an ideal loading frame for corrosion circumstances.

Feature

Corrosion Resistance

- Safety & Anti-slip

Electrical Insulating

Aging Resistance

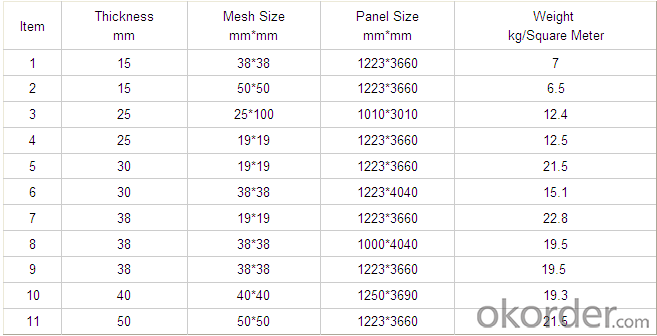

Specification

Advantage

coated with prevent aging layer

excellent insulating performance

no maintenance

- easy installation

Application

Pool railings in sewage treatment industry

Corrosive chemical industry equipment around the fence

All kinds of building maintenance section

FAQ

1. How about the documents after shipment?

After shipment, we ll send all original documents to you by DHL, including Packing List.Commercial Invoice, B/L, and other certificates as required by clients.

2. Do You Arrange Shipment?

Yes, dear esteemed customers, for FOB or CIF price, we will arrange shipment for you. For EXW price, clients need to arrange shipment by themselves or their agents.

3. How is the package?

Usually, we arrange the standard out-package for exporting.

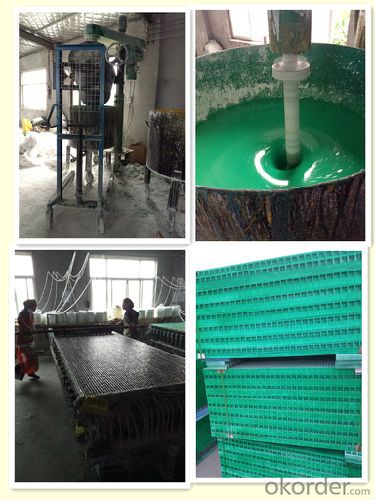

PROCESS

FACTORY

- Q: Can FRP pultrusion profiles be used in the automotive industry?

- Yes, FRP (Fiber Reinforced Plastic) pultrusion profiles can definitely be used in the automotive industry. FRP pultrusion profiles offer several advantages that make them suitable for automotive applications. Firstly, FRP pultrusion profiles are lightweight, which is a crucial factor in the automotive industry as it helps in improving fuel efficiency and reducing overall vehicle weight. Lighter vehicles have lower energy consumption and emissions, making them more environmentally friendly. Secondly, FRP pultrusion profiles have excellent strength-to-weight ratio. This means they can provide high strength and stiffness while being lightweight. This property makes them ideal for structural components in automobiles, such as chassis, body panels, and support structures. Furthermore, FRP pultrusion profiles are highly corrosion-resistant, which is a significant advantage in automotive applications. Vehicles are often exposed to harsh environmental conditions, including moisture, salt, and chemicals. The corrosion resistance of FRP helps in ensuring the longevity and durability of automotive components, even in challenging environments. Additionally, FRP pultrusion profiles have good impact resistance, which is crucial for automotive safety. They can absorb and dissipate energy during impacts, reducing the risk of injury in case of accidents. Moreover, FRP pultrusion profiles can be customized and engineered to meet specific design requirements, allowing for versatility in automotive applications. They can be designed to have specific mechanical properties, shapes, and sizes, making them suitable for various automotive components. Overall, the lightweight, high strength, corrosion resistance, impact resistance, and customization options make FRP pultrusion profiles an excellent choice for the automotive industry. They offer numerous benefits, including improved fuel efficiency, enhanced safety, and prolonged component life, making them a viable alternative to traditional materials in automotive applications.

- Q: What are the typical dimensions and sizes of FRP pultrusion profiles?

- The typical dimensions and sizes of FRP pultrusion profiles vary depending on the specific application and manufacturer. However, common dimensions range from small profiles measuring around 5mm to larger profiles exceeding 100mm in width or diameter. Lengths can also vary, typically ranging from a few meters to several meters.

- Q: Can FRP profiles replace carbon steel profiles?

- It can not be used as a cable carrier, but it can not replace the carbon steel profile. The general pultrusion section is connected with the connecting plate

- Q: Can FRP pultrusion profiles be used in the construction of agricultural structures?

- FRP pultrusion profiles have the capability to be utilized in the construction of agricultural structures. They possess various advantages that make them appropriate for agricultural applications. To begin with, FRP pultrusion profiles are both lightweight and strong, making them well-suited for the creation of agricultural structures such as greenhouses, barns, and storage facilities. Their high strength-to-weight ratio enables easy installation and reduces the overall weight of the structure, thus minimizing the need for heavy machinery during construction. Furthermore, FRP pultrusion profiles have the benefit of being corrosion-resistant. This is a critical characteristic for agricultural structures that are exposed to diverse environmental elements like moisture, chemicals, and fertilizers. Unlike traditional materials like wood or steel, FRP does not rot, rust, or corrode, ensuring the longevity and durability of the agricultural structure. Additionally, FRP pultrusion profiles possess excellent electrical insulation properties. This is particularly advantageous in agricultural applications where electrical equipment, such as lighting systems or ventilation controls, are commonly employed. The non-conductive nature of FRP eliminates the risk of electrical shocks or short circuits. Moreover, FRP pultrusion profiles are highly customizable and can be tailored to meet specific requirements. This adaptability allows for the creation of structures that are customized to the unique needs of agricultural operations, such as load-bearing capacity, dimensional accuracy, and thermal insulation. Furthermore, FRP pultrusion profiles are non-magnetic, which makes them suitable for use in agricultural structures where magnetic interference can disrupt sensitive equipment or affect crop growth. In conclusion, the utilization of FRP pultrusion profiles in the construction of agricultural structures provides numerous benefits, including lightweight construction, corrosion resistance, electrical insulation, customization options, and non-magnetic properties. These advantages establish FRP pultrusion profiles as a viable and practical choice for agricultural applications.

- Q: What is the tensile strength of FRP pultrusion profiles?

- The specific type and composition of materials used in FRP (Fiber Reinforced Polymer) pultrusion profiles can cause variations in their tensile strength. Generally, these profiles possess high tensile strength, often surpassing that of traditional construction materials like steel or aluminum. The range of tensile strength for FRP pultrusion profiles typically falls between 300 MPa (megapascals) and 1500 MPa or higher. However, it's worth noting that the tensile strength can be tailored and engineered to meet project requirements by adjusting the reinforcement materials, fiber orientation, resin matrix, and manufacturing process. Therefore, it is advisable to consult the manufacturer or supplier for accurate and specific information about the tensile strength of a particular FRP pultrusion profile.

- Q: Can FRP pultrusion profiles be used in pedestrian bridges?

- Yes, FRP pultrusion profiles can be used in pedestrian bridges. FRP (Fiber Reinforced Polymer) pultrusion profiles offer several advantages such as high strength-to-weight ratio, corrosion resistance, and durability, making them suitable for pedestrian bridge applications. These profiles can be customized to meet specific design requirements, ensuring the safe and efficient construction of pedestrian bridges.

- Q: Are FRP pultrusion profiles resistant to high-pressure water jets?

- Yes, FRP pultrusion profiles are generally resistant to high-pressure water jets due to their inherent corrosion resistance and ability to withstand harsh environmental conditions.

- Q: Can FRP pultrusion profiles be used in infrastructure projects?

- FRP pultrusion profiles are capable of being utilized in infrastructure projects, indeed. These profiles provide several benefits when compared to conventional materials, like steel and concrete. To begin with, FRP profiles possess a lightweight characteristic, while still maintaining high strength-to-weight ratios. This quality facilitates their transportation and installation, ultimately reducing construction time and expenses. Moreover, their lightweight nature ensures that they do not exert excessive loads on the supporting structures. In addition, FRP profiles exhibit resistance to corrosion. Unlike steel, FRP does not rust or corrode when exposed to harsh environmental conditions, making them ideal for infrastructure projects situated in coastal areas or regions with high humidity. This corrosion resistance extends the lifespan of the structures and diminishes maintenance requirements, resulting in long-term cost savings. Furthermore, FRP pultrusion profiles offer exceptional durability and dimensional stability. They display high resistance to fatigue, creep, and environmental degradation, guaranteeing the longevity and structural integrity of the infrastructure. Their dimensional stability also ensures that they retain their shape and structural properties over time, minimizing the risk of deformation or failure. Moreover, FRP profiles can be customized to meet specific project requirements. They can be manufactured in various shapes, sizes, and strengths, allowing for versatile applications in infrastructure projects such as bridges, walkways, railings, support structures, and utility poles. All in all, the utilization of FRP pultrusion profiles in infrastructure projects presents numerous advantages, including lightweight construction, corrosion resistance, durability, and customization options. These benefits establish FRP profiles as a viable and cost-effective alternative to traditional materials for a wide range of infrastructure applications.

- Q: Are FRP pultrusion profiles suitable for the manufacturing of antenna masts?

- Yes, FRP pultrusion profiles are suitable for the manufacturing of antenna masts. FRP pultrusion profiles offer several advantages such as high strength-to-weight ratio, corrosion resistance, and excellent electrical insulation properties. These characteristics make them ideal for antenna mast construction, as they can withstand various environmental conditions and provide reliable support for antennas.

- Q: Are FRP pultrusion profiles resistant to sulfuric acid?

- FRP pultrusion profiles display a notable resistance to sulfuric acid and this corrosion resistance is a key advantage they hold over traditional materials like steel or concrete. Sulfuric acid, known for its highly corrosive nature, poses no threat to FRP pultrusion profiles due to the inherent properties of the composite materials used in their construction. The primary reason behind the corrosion resistance of FRP profiles lies in the resin matrix that encases the reinforcing fibers. The commonly utilized resins in pultrusion, namely polyester, vinyl ester, and epoxy, exhibit remarkable chemical resistance, including resistance to sulfuric acid. However, it is essential to acknowledge that the resistance of FRP pultrusion profiles to sulfuric acid can vary based on multiple factors. The concentration and temperature of the acid, as well as the specific resin formulation employed in the profile, can impact the overall resistance. In scenarios involving highly concentrated acid or elevated temperatures, it is advisable to consult the manufacturer or supplier to ensure that the specific FRP profile meets the necessary resistance requirements. On the whole, FRP pultrusion profiles offer a high level of resistance to sulfuric acid, making them apt for a wide range of applications in industries where this corrosive substance may be present, such as chemical processing, wastewater treatment, or mining.

Send your message to us

FRP Pultrusion Profiles Molded Gratings - Fiberglass & Plastic Grating Floors in Various Colors with Best Quality

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 5000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords