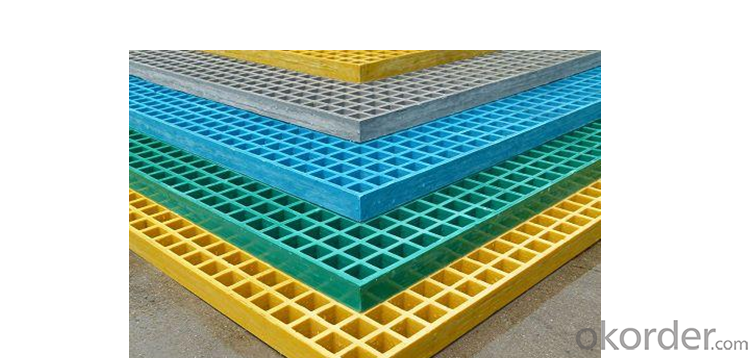

High-Quality FRP Pultrusion Profiles Molded Gratings, Fiberglass Gratings, Plastic Gratings Floor

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

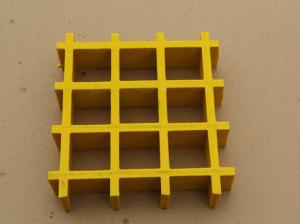

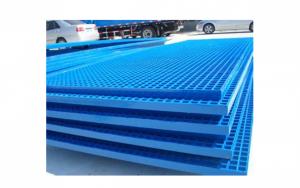

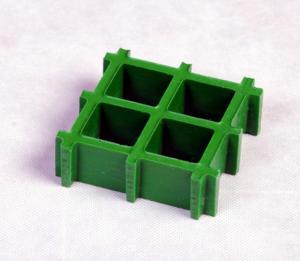

FRP Molded Grating is a structural panel which uses high-strength E-Glass roving as reinforcing material, thermosetting resin as matrix and then casted and formed in a special metal mold. It provides properties of light weight, high strength, corrosion resistance, fire resistance and anti-skid. FRP Molded Grating is widely used in oil industry, power engineering, water & waste water treatment, ocean survey as working floor, stair tread, trench cover, etc. and is an ideal loading frame for corrosion circumstances.

Feature

Corrosion Resistance

Fire Resistance

Light Weight & High Strength

Safety & Anti-slip

Electrical Insulating

Aging Resistance

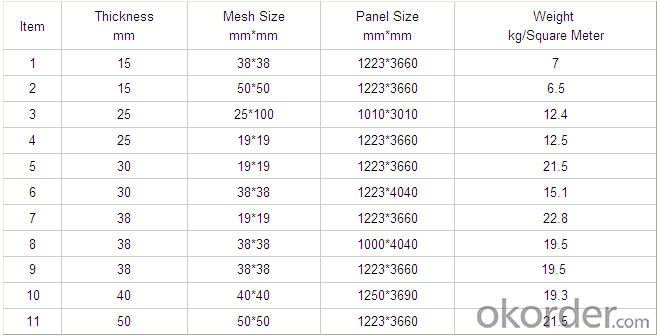

Specification

Advantage

coated with prevent aging layer

excellent insulating performance

no maintenance

high strength

long service life

easy installation

Application

- In high voltage electrical equipment for power line work, in order to prevent workers go wrong location, charged interval or near electrically charged equipment to dangerous distance.

Pool railings in sewage treatment industry

Corrosive chemical industry equipment around the fence

All kinds of building maintenance section

FAQ

1. How's the payment?

Telegraphic Transfer(T/T) or Letter of Credit(L/C)

2. Do You Arrange Shipment?

Yes, dear esteemed customers, for FOB or CIF price, we will arrange shipment for you. For EXW price, clients need to arrange shipment by themselves or their agents.

3. How is the package?

Usually, we arrange the standard out-package for exporting.

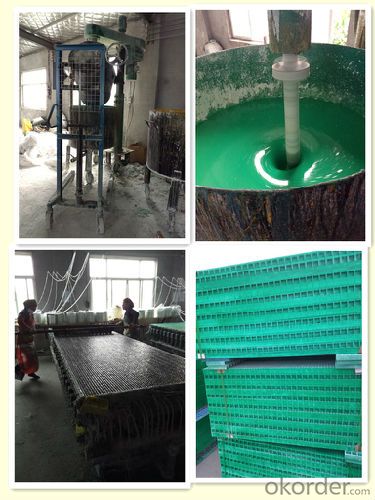

PROCESS

FACTORY

- Q: Can FRP pultrusion profiles be used in the production of electrical cabinets?

- FRP pultrusion profiles are certainly viable for incorporating into the manufacturing process of electrical cabinets. Their exceptional electrical insulating characteristics render them a fitting option for applications involving the creation of electrical cabinets. These profiles are non-conductive, thus granting insulation and safeguarding against electrical currents, ensuring the security of the electrical components encased within the cabinet. Furthermore, FRP pultrusion profiles boast a high strength-to-weight ratio, resistance to corrosion, and durability, making them a dependable choice for enduring electrical cabinets in diverse settings.

- Q: Are FRP pultrusion profiles resistant to chemical spills or leaks?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles are highly resistant to chemical spills or leaks. The combination of the fiberglass reinforcement and the polymer matrix used in FRP pultrusion provides excellent resistance to a wide range of chemicals, acids, and corrosive substances. This makes FRP pultrusion profiles a suitable choice for applications where chemical resistance is crucial, such as in chemical processing plants, wastewater treatment facilities, and storage tanks.

- Q: Are FRP pultrusion profiles resistant to chemicals used in food packaging?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles are generally resistant to chemicals used in food packaging. FRP materials are known for their excellent resistance to a wide range of chemicals, including those commonly used in food packaging such as acids, bases, solvents, and oils. This chemical resistance makes FRP pultrusion profiles a suitable choice for applications involving contact with food packaging materials. However, it is important to note that the specific resistance of FRP profiles may vary depending on the formulation and type of resin used. Therefore, it is advisable to consult with the manufacturer or supplier to ensure that the chosen FRP pultrusion profiles are suitable for the specific chemicals used in the food packaging industry.

- Q: Are FRP Pultruded Shapes poisonous?

- The use of food grade resins, pultruded extrusions, is not toxic, and this can be applied to Waterworks

- Q: Can FRP pultrusion profiles be used in pedestrian bridges?

- FRP pultrusion profiles can indeed be utilized in pedestrian bridges. They possess several advantages that render them appropriate for bridge construction, including their exceptional strength-to-weight ratio, resistance to corrosion, and durability. These profiles are manufactured by pulling continuous fibers through a resin bath and subsequently through a heated die, yielding a material that is both robust and lightweight. The lightweight nature of FRP pultrusion profiles makes them an ideal choice for pedestrian bridges, as they can be easily transported and installed. Furthermore, their high strength enables them to withstand the load requirements imposed by pedestrian traffic. Moreover, these profiles exhibit exceptional resistance to corrosion, which is particularly crucial for bridges that are exposed to environmental elements such as rain, humidity, and saltwater. In addition, FRP pultrusion profiles are highly durable and necessitate minimal maintenance in comparison to traditional construction materials like steel or concrete. They are impervious to rust or rot, and their non-conductive properties guarantee their safety when employed in areas with electrical infrastructure. To summarize, FRP pultrusion profiles present a suitable option for pedestrian bridges due to their lightweight nature, high strength, resistance to corrosion, and durability. These profiles offer a cost-effective and long-lasting solution for bridge construction, ensuring the safety and convenience of pedestrians.

- Q: What is the dimensional stability of FRP pultrusion profiles?

- The dimensional stability of FRP (Fiber Reinforced Polymer) pultrusion profiles is generally very high. This is due to the unique structural characteristics of FRP materials and the pultrusion manufacturing process. FRP pultrusion profiles are made by pulling continuous fibers, such as glass or carbon, through a resin bath and then through a heated die. The resin is typically a thermosetting polymer, which means it undergoes a chemical reaction during the curing process to become a rigid and durable material. The pultrusion process ensures that the fibers are evenly distributed and aligned within the profile, resulting in a highly uniform and consistent material. This uniformity contributes to the dimensional stability of FRP pultrusion profiles. Furthermore, the thermosetting nature of the resin matrix provides excellent dimensional stability. Once the resin is cured, it retains its shape and dimensions even under varying temperature and humidity conditions. This makes FRP pultrusion profiles resistant to warping, shrinking, or expanding, which can occur in other materials like wood or metals. The high dimensional stability of FRP pultrusion profiles makes them ideal for a wide range of applications where precise and consistent dimensions are required. These profiles are commonly used in industries such as construction, infrastructure, transportation, and marine, where their ability to maintain their shape and dimensions over time is crucial for long-term performance and structural integrity.

- Q: What are the quality control measures for FRP pultrusion profiles?

- To ensure the desired standards are met, a series of steps and processes are involved in quality control measures for FRP pultrusion profiles. These measures encompass: 1. Inspection of raw materials: The initial step involves verifying the quality of the raw materials used in the pultrusion process. This entails assessing the properties and specifications of components such as fiberglass, resin, additives, and others. 2. Control of the process: Throughout the pultrusion process, it is crucial to monitor and control various parameters. This includes maintaining consistent temperature, pressure, and resin content during impregnation, forming, and curing stages. 3. Testing of samples: Regular sampling is conducted during production to evaluate profile quality. Mechanical properties, dimensional accuracy, and surface finish are tested to ensure they align with the required standards. 4. Visual examination: Each profile undergoes visual inspection to identify any defects, such as cracks, voids, delamination, or surface imperfections. This examination aids in detecting irregularities that may impact the profiles' structural integrity or aesthetics. 5. Mechanical assessment: Profiles are subjected to mechanical testing to evaluate strength, stiffness, and other mechanical properties. Flexural, tensile, impact, and compression tests are conducted, comparing the results to specified requirements to determine compliance with necessary standards. 6. Documentation of quality: Proper documentation is maintained throughout the manufacturing process, encompassing records of raw material specifications, process parameters, test results, and inspection reports. This ensures traceability and serves as a reference for quality assurance. 7. Non-destructive testing: In addition to mechanical testing, non-destructive techniques like ultrasonic testing or X-ray inspection may be employed to identify internal defects or inconsistencies without causing damage to the profiles. 8. Quality audits: Regular internal and external audits are performed to evaluate the effectiveness of quality control measures and ensure adherence to relevant industry standards and regulations. By incorporating these quality control measures, manufacturers can guarantee that FRP pultrusion profiles meet the necessary specifications, resulting in dependable and high-quality products.

- Q: How do FRP pultrusion profiles perform in high-wind areas?

- Due to their exceptional performance characteristics, FRP pultrusion profiles are highly suitable for use in high-wind areas. These profiles utilize a combination of continuous glass fibers and a polymer resin matrix, resulting in a material that is both lightweight and incredibly strong and durable. One major advantage of FRP pultrusion profiles in high-wind areas is their excellent resistance to corrosion. Unlike traditional materials like steel or wood, FRP does not rust or rot when exposed to moisture or harsh weather conditions. This makes them ideal for regions prone to hurricanes or coastal environments where wind-driven saltwater or heavy rain can cause accelerated deterioration in other materials. In addition, FRP pultrusion profiles have a high strength-to-weight ratio, allowing them to withstand high wind loads without adding excessive weight to structures. Their lightweight nature makes transportation and installation easy, reducing overall costs and construction time in high-wind areas. Furthermore, FRP pultrusion profiles exhibit excellent dimensional stability, meaning they resist warping or deforming under extreme wind pressures. This stability ensures that structures utilizing FRP profiles maintain their integrity and functionality even in the face of strong winds. Moreover, FRP pultrusion profiles can be customized to meet specific wind load requirements. They can be engineered to have specific flexural or tensile strengths, allowing for tailored solutions to suit the demands of high-wind areas. Overall, FRP pultrusion profiles are an excellent choice for structures in high-wind areas due to their corrosion resistance, high strength-to-weight ratio, dimensional stability, and customization capabilities. These profiles provide a reliable, long-lasting, and cost-effective solution for structures exposed to intense wind loads, ensuring the safety and durability of the built environment.

- Q: Can FRP pultrusion profiles be used in telecommunications towers?

- Telecommunications towers can indeed utilize FRP (Fiber Reinforced Polymer) pultrusion profiles. These profiles possess several advantageous features that render them suitable for this particular application. Firstly, FRP profiles possess a lightweight yet robust nature, facilitating effortless installation and reducing the overall structural weight of telecommunications towers. This characteristic is crucial as it aids in minimizing the burden imposed on the tower structure. Secondly, FRP pultrusion profiles exhibit exceptional resistance to corrosion, making them ideally suited for outdoor applications such as telecommunications towers that are constantly exposed to diverse environmental conditions. Unlike conventional materials like steel or wood, FRP profiles do not succumb to rust, rot, or deterioration when subjected to moisture, UV radiation, or chemicals typically encountered in outdoor environments. Additionally, FRP pultrusion profiles offer excellent electrical insulation properties, a critical aspect for telecommunications towers. These profiles are non-conductive, thereby reducing the likelihood of electrical interference or short circuits that might disrupt the tower's communication systems. Moreover, FRP pultrusion profiles can be produced in various shapes and sizes, thereby enabling customization and meeting the specific design requirements of telecommunications towers. This versatility facilitates seamless integration and compatibility with other components of the tower. Overall, the combination of lightweight composition, high strength, corrosion resistance, electrical insulation, and customization options renders FRP pultrusion profiles an advantageous and viable selection for utilization in telecommunications towers.

- Q: Are FRP pultrusion profiles UV resistant?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles are typically UV resistant. This is because they are manufactured using a combination of polymer resin and reinforced fibers such as fiberglass. These materials have inherent UV resistant properties, making FRP pultrusion profiles resistant to damage caused by prolonged exposure to sunlight and ultraviolet radiation. UV resistance is a crucial characteristic for outdoor applications where the profiles will be exposed to sunlight, such as in construction, infrastructure, and marine industries. However, it is important to note that the level of UV resistance may vary depending on the specific resin and fiber composition used in the manufacturing process. Therefore, it is recommended to consult the manufacturer or supplier for specific information on the UV resistance of FRP pultrusion profiles for a particular application.

Send your message to us

High-Quality FRP Pultrusion Profiles Molded Gratings, Fiberglass Gratings, Plastic Gratings Floor

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords