FRP Grille/Fiberglass Grille with High Strength

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 5000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Structure of FRP Grille Description

As a composite of continuous fiberglass strands and high quality resin is integrally constructed for strength, but it is less than one-half the weight of steel grating allowing easy removal for access below floor level and installation with no heavy equipment and less manpower.

2. Main Features of FRP Grille

1) Cost effective

2) Anti corrosion

3) Impact resistance

4) light weight

5) Easy installation

6) Low maintenance

7) no rust

8) Longevity

9) Aesthetically appealing

10) Large range mesh sizes and thickness

3. FRP Grille Images

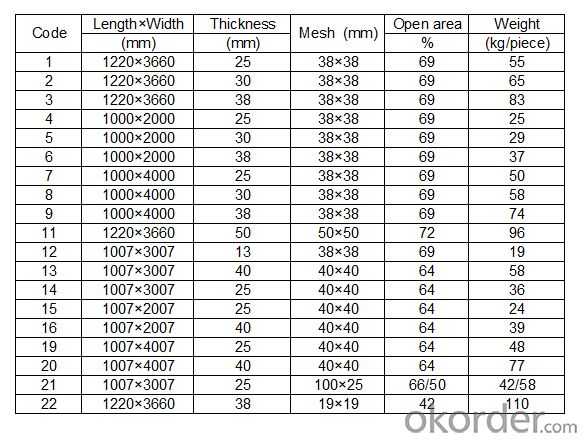

4. FRP Grille Specification

5. FAQ of FRP Grille

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

One of the leading manufacturers and suppliers specializing in FRP products in China. The integrated sales & service ensures customers with various demands an easier access for purchasing management.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible.

- Q: FRP pipe price

- FRP prices are calculated in terms of material length and nozzle diameter.FRP duct price is: 3mm specifications 66 yuan / square meter, 4mm specifications 88 yuan / square meter, 5mm specifications 110 yuan / square meter, 6mm specifications 130 yuan / square meter, 7mm specifications 150 yuan / square meter

- Q: Glass fiber reinforced plastic pipe to withstand 1.0MPa pressure, pipe wall to do how much thickness?

- Glass tube wall thickness is generally determined by the manufacturer design, with stereotypes products and sequences, you can choose according to the pressure level.

- Q: Glass fiber reinforced plastic GRE pipe broken hole how to repair and repair?

- Resin selection of good points, the general also line, as well as accelerators, curing agents, high-quality glass fiber cloth.

- Q: What's the difference between glass fiber reinforced plastic pipe and glass fiber reinforced sand pipe? What kind of material is good?

- Other fields such as chemical industry, the product is relatively high, generally aerial or ground, even if there is high pressure, bad high risk, so even high stiffness is thicker instead of sand, in general, not afraid of high investment, the use of pure glass tube, don't use the sand tube.

- Q: What is the difference between glass tube, sand pipe and glass tube?

- Glass reinforced plastic sand pipe is actually in the production of glass fiber reinforced plastic pipe, in the middle to increase a layer of sand layer, the purpose is to increase the rigidity of the pipeline.

- Q: How much is a glass fiber reinforced plastic sand pipe socket pipe fitting?

- Compared with the traditional pipe, it has excellent chemical resistance. It can resist acid, alkali, salt, oxidant, organic solvent, various kinds of grease, sewage and so on. Its lining is made of corrosion resistant and excellent resin as raw material, so no corrosion protection is needed. And after long-term use, no fouling, will not be contaminated by micro-organisms and debris deposition in the sewage, so as to increase the roughness rate and reduce the water cross section or plug the pipeline. Because the damage rate of glass fiber reinforced sand pipe is more than 4 times the working pressure, the safety factor is designed with enough safety factor.

- Q: What are the advantages of glass fiber reinforced plastic sand pipe than HDPE pipe?

- Both have their merits, but it depends on their choice!

- Q: Are there any differences between FRP pipes and FRP pipes?

- The mechanism glass magnesium composite pipe is made of glass cloth, magnesium and earth, which is hard to burn. The glass fiber reinforced plastic pipe is made of glass cloth and resin, and it is inflammable and light in weight.

- Q: What epoxy resin is used for anticorrosion of pipeline glass fiber reinforced plastics?

- General glass fiber reinforced plastic, no corrosion protection.If buried with epoxy coal pitch can be, anti rust grade Sa2.5, six oil four cloth can.

- Q: Uneven settlement of the foundation, can lead to glass fiber reinforced plastic underground water pipes burst, what is the principle?

- Dislocation will cause the pipe to burst. The pressure is different, and the pipe will burst

Send your message to us

FRP Grille/Fiberglass Grille with High Strength

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 5000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords