High Quality FRP Pultrusion Profiles for Wind Turbine Blades

- Loading Port:

- Lianyungang

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000000 watt

- Supply Capability:

- 833 watt/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

FRP Blades Wind Turbine Blades of High Quality

General Description about Our Wind Turbine Baldes:

Sinoma Wind Power Blade bases have been established in Funing of Jiangsu,Handan of Hebei Province, Pingxiang of Jiangxi Province, Jiuquan of Gansu, Xilingol of Inner Mongolia, Baicheng of Jilin Province, and Hinggan League of Inner Mongolia, with annual total production capacity reaching equivalent to 10GW.

Sourcing from natural wind keeping a sustainable world. Sinoma Blade is committed to building the most customers respect and employees, shareholders trust with the global competitiveness of the world’s first-class wind power blade enterprises.

Detailes about our Wind Turbine Blades:

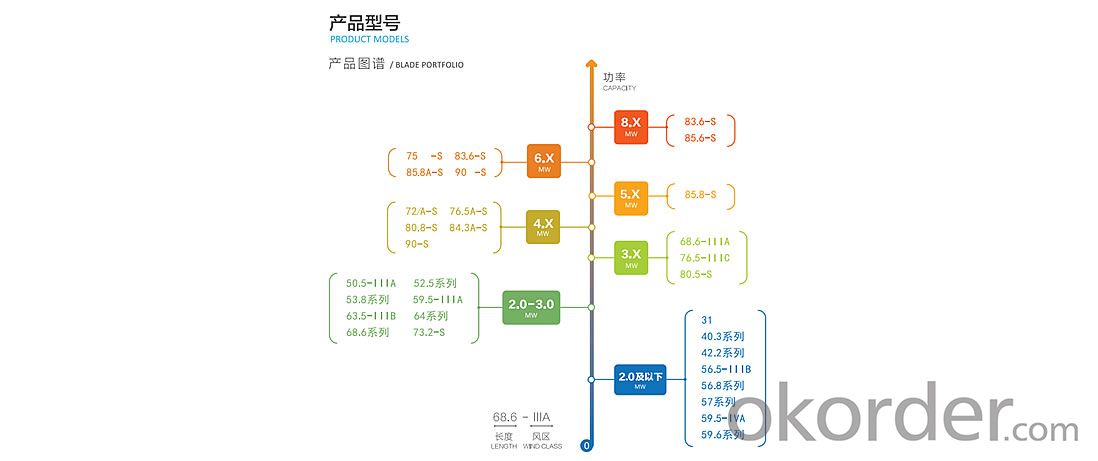

Our Blades has below type :

PROJECT REFERENCE:

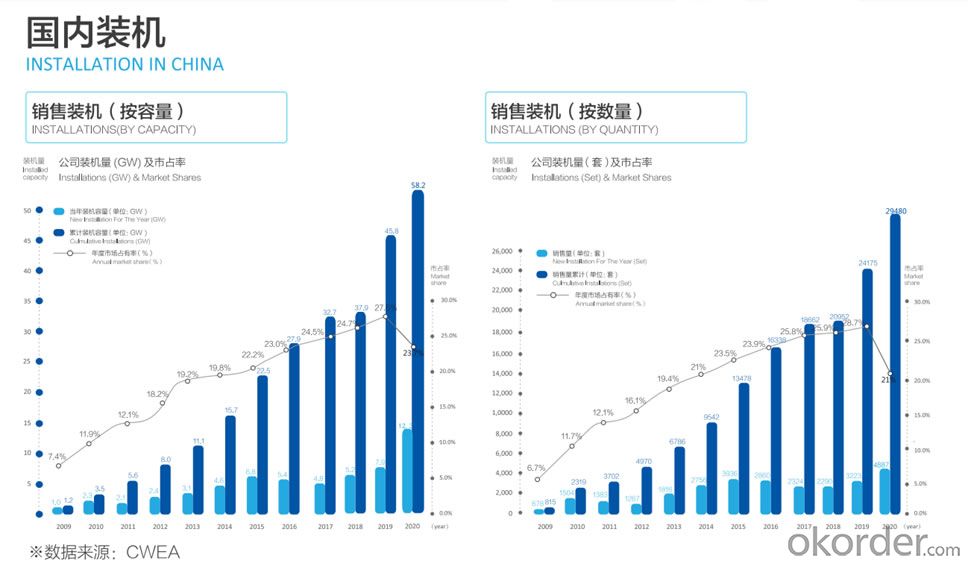

THE DOMESTIC MARKET:

THE GLOBAL INSTALLATION:

By end of June 2021, 30883 sets of blades (63580MW) are installed.

Including 1628 sets (4386.1MW) installed in 24 countries overseas.

- Q: Can FRP pultrusion profiles be used in the construction of outdoor signage?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles can be used in the construction of outdoor signage. FRP pultrusion profiles are known for their durability, strength, and resistance to various environmental conditions, making them suitable for outdoor applications. These profiles are typically made of a combination of fiberglass reinforcement and resin matrix, resulting in a lightweight yet strong material. Outdoor signage often needs to withstand harsh weather conditions, such as rain, sun exposure, and temperature fluctuations. FRP pultrusion profiles have excellent resistance to corrosion, UV rays, and moisture, ensuring that the signage can maintain its structural integrity and visual appeal over time. Furthermore, FRP pultrusion profiles can be customized to meet specific design requirements, allowing for flexibility in creating unique and eye-catching outdoor signage. These profiles can be easily shaped, cut, and assembled, making them a versatile choice for signage applications. In summary, FRP pultrusion profiles can indeed be used in the construction of outdoor signage due to their durability, resistance to environmental conditions, and flexibility in design.

- Q: Are FRP pultrusion profiles resistant to alkalis?

- FRP pultrusion profiles are generally able to resist alkalis. This is because FRP composites are materials made of a polymer matrix reinforced with fibers like glass or carbon. The polymer matrix in FRP pultrusion profiles has excellent resistance to alkalis, making them suitable for use in places where alkalis are present, such as chemical processing plants, wastewater treatment facilities, or marine structures. However, the resistance of FRP pultrusion profiles to alkalis may vary depending on factors like the type of polymer resin used and the concentration and temperature of the alkali solution. Therefore, it is important to refer to the manufacturer's specifications or perform specific tests to ensure that FRP pultrusion profiles are compatible with the intended alkali environment.

- Q: Can FRP pultrusion profiles be used in agricultural structures?

- Yes, FRP pultrusion profiles can be used in agricultural structures. FRP (Fiber Reinforced Polymer) pultrusion profiles offer several advantages that make them suitable for agricultural applications. Firstly, FRP profiles are corrosion-resistant, which is crucial in the agricultural industry where structures are exposed to harsh environments and chemicals, such as fertilizers and pesticides. Unlike traditional materials like steel or wood, FRP does not rust or decay, ensuring long-lasting performance in agricultural structures. Secondly, FRP profiles are lightweight yet durable, making them easy to handle and install in agricultural applications. They have high strength-to-weight ratios, allowing for efficient construction and reducing the need for heavy machinery during installation. Additionally, FRP profiles offer excellent mechanical properties such as high stiffness and impact resistance, which are beneficial for agricultural structures that may face heavy loads, vibrations, or impact from machinery. Furthermore, FRP pultrusion profiles can be designed to be UV resistant, preventing degradation from prolonged exposure to sunlight. This makes them suitable for outdoor agricultural structures that are constantly exposed to the elements. Lastly, FRP profiles are non-conductive, which is advantageous in agricultural environments where electrical safety is critical. This property eliminates the risk of electrical hazards associated with conductive materials like steel. Overall, FRP pultrusion profiles provide a reliable and efficient solution for various agricultural structures, such as greenhouse frames, livestock enclosures, irrigation systems, and storage facilities. Their corrosion resistance, lightweight nature, high strength, UV resistance, and non-conductivity make them a suitable choice for agricultural applications.

- Q: Can FRP pultrusion profiles be used in pedestrian bridges?

- Yes, FRP pultrusion profiles can be used in pedestrian bridges. FRP (Fiber Reinforced Polymer) pultrusion profiles offer several advantages such as high strength-to-weight ratio, corrosion resistance, and durability, making them suitable for pedestrian bridge applications. These profiles can be customized to meet specific design requirements, ensuring the safe and efficient construction of pedestrian bridges.

- Q: What are the environmental benefits of using FRP pultrusion profiles?

- Using FRP (Fiber Reinforced Polymer) pultrusion profiles offers several environmental advantages. To begin with, FRP pultrusion profiles are lightweight and possess a high strength-to-weight ratio. This means that less material is needed to achieve the same structural integrity as traditional materials like steel or concrete. Consequently, the production and transportation of FRP profiles consume less energy and result in fewer greenhouse gas emissions. Additionally, FRP pultrusion profiles exhibit exceptional durability and resistance to corrosion. This extends their lifespan and reduces the frequency of replacements required. As a result, resources are conserved, and the amount of waste ending up in landfills or requiring recycling is reduced. Moreover, FRP is non-conductive, making it an excellent alternative to metals in electrical applications. This property eliminates the risk of electrical accidents and decreases the necessity for insulation, which often involves hazardous substances. Furthermore, the manufacturing process of FRP pultrusion profiles generally requires lower energy inputs compared to other materials. The pultrusion process itself is energy-efficient, and the raw materials used in FRP production, such as resins and fibers, can be obtained from renewable or recycled sources. Lastly, FRP pultrusion profiles are chemically inert and do not release harmful substances into the environment. This characteristic makes them suitable for various applications, including water treatment plants, where preventing chemical leaching is crucial for maintaining water quality. In conclusion, the use of FRP pultrusion profiles brings about environmental benefits such as reduced energy consumption, lower greenhouse gas emissions, prolonged product lifespan, decreased waste generation, reduced dependence on non-renewable resources, and minimized chemical leaching. These advantages establish FRP as a sustainable and eco-friendly choice for a wide array of industries.

- Q: Are FRP pultrusion profiles resistant to acids?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles are generally resistant to acids. The corrosion resistance of FRP is one of its key advantages over traditional materials like steel or wood. The composite materials used in FRP pultrusion profiles offer excellent resistance to a wide range of acids, including both organic and inorganic acids. The corrosion-resistant properties of FRP pultrusion profiles can be attributed to the chemical composition of the composite materials. The reinforcing fibers, such as glass or carbon fibers, are highly resistant to acid attack. Additionally, the polymer matrix used in FRP provides a protective barrier against acid penetration. However, it is important to note that the resistance of FRP pultrusion profiles to acids can vary depending on the specific type of acid and the concentration. While FRP is generally resistant to most acids, there may be certain aggressive acids or highly concentrated solutions that can cause some level of degradation over time. To ensure optimal performance and longevity, it is recommended to consult with the manufacturer or supplier of FRP pultrusion profiles for specific information regarding their resistance to acids. They can provide valuable guidance on the suitability of FRP profiles for specific applications involving acids and recommend any additional protective measures, such as coatings or liners, if required.

- Q: Are FRP pultrusion profiles resistant to jet fuel?

- Yes, FRP pultrusion profiles are generally resistant to jet fuel.

- Q: Are FRP pultrusion profiles fire resistant?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles are fire resistant. The combination of the reinforcing fibers and the polymer matrix used in FRP pultrusion profiles provide them with excellent fire resistance properties. These profiles are manufactured using a process known as pultrusion, which involves impregnating reinforcing fibers such as fiberglass or carbon fiber with a thermosetting resin. This resin undergoes a curing process, resulting in a strong and durable composite material. One of the key advantages of FRP pultrusion profiles is their inherent fire resistance. The thermosetting resin used in the manufacturing process has properties that make it highly resistant to fire. When exposed to flames or high temperatures, the resin does not melt or burn easily, thus preventing the spread of fire. Additionally, the reinforcing fibers in FRP profiles also contribute to their fire resistance. Fiberglass, for example, is an inorganic material that does not burn. It acts as a barrier against heat transfer and helps to minimize the spread of flames. Furthermore, FRP pultrusion profiles can be engineered to meet specific fire safety standards and regulations. By incorporating additional fire retardant additives or using specialized resin systems, the fire resistance of these profiles can be further enhanced. It is important to note that while FRP pultrusion profiles are fire resistant, their exact fire rating may vary depending on the specific composition and design. Therefore, it is essential to consult with manufacturers or suppliers who can provide detailed information about the fire resistance properties of their FRP pultrusion profiles.

- Q: Can FRP pultrusion profiles be used in the construction of theme park rides?

- Yes, FRP pultrusion profiles can be used in the construction of theme park rides. FRP (Fiber Reinforced Polymer) pultrusion profiles are known for their high strength-to-weight ratio, corrosion resistance, and durability, making them suitable for various structural applications. These profiles can be used to build ride components such as supports, beams, frames, and safety structures, providing a lightweight yet robust solution for theme park rides.

- Q: Are FRP pultrusion profiles non-conductive?

- FRP pultrusion profiles are non-conductive because they consist of reinforced fibers, usually fiberglass, and a polymer resin matrix. The fiberglass fibers provide strength and stiffness, while the polymer resin acts as a binder. One of the main advantages of FRP pultrusion profiles is their excellent electrical insulation properties. Unlike metals, which conduct electricity, FRP profiles do not. This makes them ideal for applications that require electrical insulation. In addition to being non-conductive, FRP pultrusion profiles also offer other advantages like corrosion resistance, a high strength-to-weight ratio, and low maintenance requirements. These properties make them suitable for various applications such as electrical and telecom infrastructure, chemical processing plants, bridges, and building construction. It is worth noting that while FRP pultrusion profiles are non-conductive by default, they can be made conductive if necessary. Special additives or coatings can be added during the manufacturing process to give them conductive properties.

Send your message to us

High Quality FRP Pultrusion Profiles for Wind Turbine Blades

- Loading Port:

- Lianyungang

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000000 watt

- Supply Capability:

- 833 watt/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords