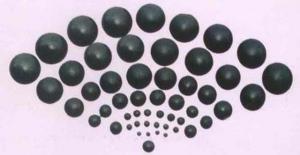

Forged Steel Grinding Ball With Supper Hardness Apply For All Kinds Of Mineral Processing

- Loading Port:

- Shanghai Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25M.T. m.t.

- Supply Capability:

- 200000M.T./Year m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Feature of Forged Steel Grinding Ball with Supper Hardness apply for all kinds of Mineral Processing

1) In general, grinding steel ball has high hardness: surface hardness to 58-65 HRC, volume hardness of 56-65 HRC

2) impact toughness high: impact toughness more than 12 J / cm2.

3) broken rate is low: the actual broken rate is not higher than 0.5%.

4) loss of grinding forged steel ball round rate is low.

2.Chemical Composition of Forged Steel Grinding Ball with Supper Hardness apply for all kinds of Mineral Processing

Based on material, the forged steel balls are defined into3 brands. And The chemical composition is shown in the following:

Brand | C | Mn | Si | Cr | S | P | V |

1A | 0.37-0.55 | 0.50-1.0 | 0.17-0.47 | 0.80-1.2 | ≤0.035 | ≤0.035 | |

2A | 0.7-1.00 | 0.7-1.0 | ≤0.025 | 0.4-0.8 | ≤0.025 | ≤0.025 | |

65 | 0.55-0.70 | 0.80-1.25 | 0.17-0.47 | ≤0.25 | ≤0.035 | ≤0.035 |

3.Specification of Forged Steel Grinding Ball with Supper Hardness apply for all kinds of Mineral Processing

Nominal Diameter | Diameter Tolerance | Weight of Single Ball | Numbers of Per Ton |

(mm) | (mm) | (g) | 32150 |

20 | +2 -1 | 32 | 15625 |

25 | 64 | 9090 | |

30 | 110 | 5645 | |

40 | 263 | 3802 | |

50 | 513 | 1949 | |

60 | +3 -2 | 888 | 1126 |

70 | 1410 | 709 | |

80 | 2104 | 485 | |

90 | 2996 | 333 | |

100 | 4110 | 243 | |

110 | +4 -2 | 5457 | 182 |

120 | 7102 | 140 | |

130 | 9030 | 110 | |

140 | 11279 | 88 | |

150 | 13871 | 72 |

- Q: How is the silicon sol precision casting part priced? What is the price per ton of casting? Such as 304 material.

- Yantai five God casting is generally 53 yuan /kg, the appearance is quite beautiful

- Q: What's the effect of casting copper?

- In general cast iron, the mass fraction of copper below 3% - 3.5% can increase the hardness; but when the cast iron has a tendency to chill, or when there is a hard point of free carbides, the addition of copper decreases the hardness.Copper can be used to improve the wear resistance, abrasion resistance, and shock absorption of cast iron, so it is often used in the manufacture of sliding friction iron castings, such as drilling machine spindle, automobile and tractor, valve tappet, etc.. But in white cast iron or chilled cast iron, adding copper does not make any improvement in its abrasion resistance.Copper for certain heat resistant cast iron and austenitic cast iron can increase the heat resistance and corrosion resistance, copper - chromium composite alloy to prevent oxidation under high temperature in the atmosphere from the skin effect is particularly effective, heat resistance and corrosion resistance of austenitic cast iron containing many mass fraction of 4% ~ 7% copper.

- Q: What are the requirements for casting steel castings?

- 1, high quality requirements of the surface or the main processing surface should be placed below.

- Q: What is the difference between forging parts and casting parts?

- No, it's called die castingDifference: the die casting parts are simple in structure and large in batch sizeCasting: the use of a wide range of structures without restrictions

- Q: The cause of fracture and why there is no toughness

- This question is too broad, see what the casting casting Oh in order to reduce the wayward cast steel, ductile iron, gray iron and white iron, you can choose the material according to their own requirements.

- Q: For example, casting parts contain many holes, inclusions and other defects, the size and the number of holes exceed which limit is not qualified

- For example, the castings shall be in accordance with the requirements of the second types of castings in the technical requirements for aluminum alloy castings of GB/T9438-1999;

- Q: How do you mark it on the drawing? Do you need to discuss it with the manufacturer?Because the casting allowance is the standard, then, after all, is the theoretical value, the actual level depends on the manufacturer, so is it necessary to ask the manufacturer?

- Casting parts do not need to provide drawings of casting blank, the casting factory according to your drawings in the required surface will be sufficient allowance, and the rest of the size according to the mechanical design manual and the casting manual can be found.

- Q: What is the difference between casting and stamping parts?

- The purpose of forming processes is to allow the sheet to undergo plastic deformation without breaking the billet and to make the desired shape and size. In actual production, a variety of processes are often applied to a workpiece. Blanking, bending, shearing, drawing, bulging, spinning and rectification are several main stamping processes. The difference between stamping parts and castings: with thin, uniform, light, strong features, stamping can be produced by other methods difficult to make, with stiffeners, ribs, UPS or flanging of the workpiece, to improve its rigidity. Due to the use of precision molds, the workpiece accuracy up to microns, and repeated high precision, specifications consistent, you can punch out of the hole, lug and so on.

- Q: What foundry factories are used in the casting parts of China's major automobile manufacturers?

- For example Changchun FAW, under a casting, two casting and other casting plant, but there are more than half of all outsourcing in Tianjin Hebei Shandong purchase, many automobile enterprises to casting foundry.

- Q: How to solve casting defect casting?

- Different defects, different solutions, some shortcomings, the current domestic level can not be resolved

1. Manufacturer Overview

| Location | Jiangyin City, Jiangsu Province, China |

| Year Established | 2012 |

| Annual Output Value | Above US$100 Million |

| Main Markets | South America; Oceania; Eastern Europe; Africa |

| Company Certifications | ISO9001;IS014001 Certificate |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Qingdao Port; Tianjin Port; Shanghai Port |

| Export Percentage | |

| No.of Employees in Trade Department | 5 - 10 People |

| Language Spoken: | English; Chinese; Spanish; Portuguese; Russian |

| b) Factory Information | |

| Factory Size: | 10,000-30,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | Grinding Ball; Grinding Rod; Cylpeb; Grinding Media; Ball Mill Ball |

| Product Price Range | Average |

Send your message to us

Forged Steel Grinding Ball With Supper Hardness Apply For All Kinds Of Mineral Processing

- Loading Port:

- Shanghai Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25M.T. m.t.

- Supply Capability:

- 200000M.T./Year m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords