Applied fields of Rolling Forged Steel Grinding Ball with Supper Hardness apply for all kinds of Mineral Processing

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25M.T. m.t.

- Supply Capability:

- 200000M.T./Year m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

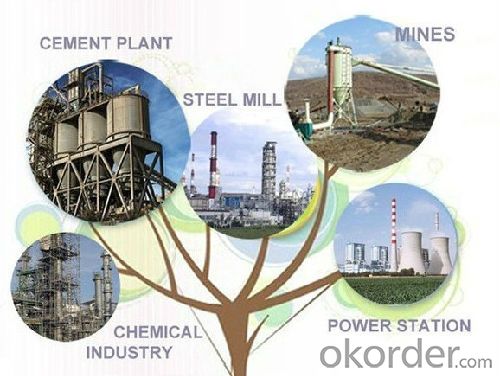

1. Applied Field of Forged Steel mineral ues Grinding Ball with High Hardness and Low Breakage Rate

1) Power Plant, 2) Mineral Processing,

3) Refractory Factory, 4) Cement Plant

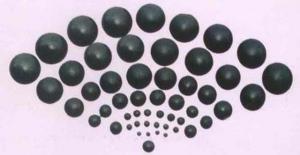

2. Specification of Forged Steel mineral ues Grinding Ball with High Hardness and Low Breakage Rate

Metrial: Mn65,Mn50,Mn60, High and low chrome cast steel

Size: 20mm-150mm

Hardness:HRC58-65; Chrome content:11-14%

3. Packing Information of Forged Steel mineral ues Grinding Ball with High Hardness and Low Breakage Rate

Container Bags: 1000Kgs/Container Bag

Steel Drums: 850Kgs/Drum

4. Photos of Forged Steel mineral ues Grinding Ball with High Hardness and Low Breakage Rate

- Q: There is a little trace of polishingShock polishing is even worseElectrolysis can not be uneven, there is a slight bump

- German winter three step mirror polishing 2013 new processYou can free proofing!

- Q: How to calculate the price of casting parts?

- Cost of raw materials + electricity (fuel) costs + workers' wages + managers' wages + transport costs + raw materials burned + accessories costs + equipment maintenance depreciation costs + management fees + tax. The most convenient, the raw material market price plus 2000 yuan, plus you want profits on the line.

- Q: How to improve the surface roughness of casting parts?

- First, the accuracy of the model should be improved; two is to change the molding technique; the three is the coating; and the worker's technical level.

- Q: How to distinguish the forging parts and casting parts accurately

- Distinguishing between forging and casting can be done from the following points:From the principle of distinguishingForging processing of machining by hammer or press and other equipment for forging parts produced in hot state, casting processing of metals into liquid, pouring into the cavity with a specific shape, produced by machining parts after cooling solidification. Simply say that forging is the metal soft pinch molding, and casting the metal into thin cooling solidification.

- Q: What is the difference between casting and stamping parts?

- Cold stamping is generally no longer done by cutting, or only a small amount of cutting is required. The precision and surface state of hot stamping parts are lower than those of cold stamping parts, but they are better than those of castings and forgings, and the amount of cutting is less.Stamping is mainly based on process classification, can be divided into separation process and forming process two major categories.

- Q: Where is the precision casting factory?

- Shandong, DongyingThe birthplace of precision casting

- Q: What kind of flaw detector is better for casting parts?

- Casting using the detector test, you must first determine the detection process, such as the detection of surface and near surface crack defects, such as casting, recommended by CYD-3000, or CYD-5000 mobile magnetic testing machine for testing.

- Q: Which surface is coarser for cast iron or cast steel castings? Why?

- The surface of the steel is more rough, because the coating sand cast steel cast iron particles compared with graphite coating degree, the other one is to get a better air permeability and collapsibility of sand, the compaction degree is smaller than iron.

- Q: Why should pig iron be used in casting?

- 1, in the absence of special requirements, the most important thing is that the price is cheap.2, pig iron castings quenching process requirements are not high. You can do it by hand.3, pig iron casting hardness is very large, can meet many requirements.4, pig iron castings, high temperature resistance is relatively strong. Like stoves are pig iron castings.5, pig iron casting plasticity is very bad, but in some experiments, but use this weakness to improve the sensitivity of the experiment.Wait

- Q: What foundry factories are used in the casting parts of China's major automobile manufacturers?

- For example Changchun FAW, under a casting, two casting and other casting plant, but there are more than half of all outsourcing in Tianjin Hebei Shandong purchase, many automobile enterprises to casting foundry.

1. Manufacturer Overview

| Location | Shandong, China |

| Year Established | 1971 |

| Annual Output Value | US$50 Million - US$100 Million |

| Main Markets | Domestic Market, Southeast Asia, South Asia, North America, South America |

| Company Certifications | ISO9001;IS014001 Certificate |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Qingdao Port |

| Export Percentage | |

| No.of Employees in Trade Department | 6-10 People |

| Language Spoken: | English, Chinese, Korean |

| b) Factory Information | |

| Factory Size: | Above 60,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | Forged Grinding Ball,Cast Grinding Ball,Casting Cylpebs,Grinding Rods,Decorative Steel Ball |

| Product Price Range | Average |

Send your message to us

Applied fields of Rolling Forged Steel Grinding Ball with Supper Hardness apply for all kinds of Mineral Processing

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25M.T. m.t.

- Supply Capability:

- 200000M.T./Year m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords