Forged Flanged End Ball Valve/ Válvula de bola con bridas Fin forjado

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 set

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging & Delivery

| Packaging Detail: | Standard Export and Sea-worthy Plywood Case |

| Delivery Detail: | 30 Days |

Specifications

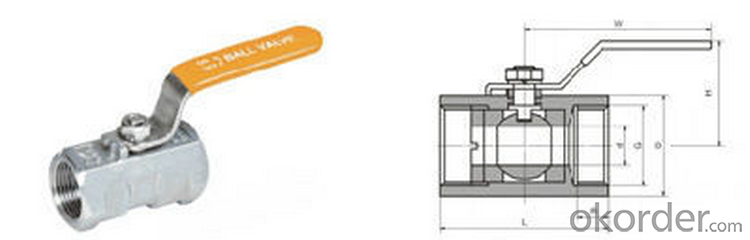

NPS 2"~36"

ANSI CLASS 150~2500

MATERIAL: WCB, LCB, CF8, CF8M, CF3, CF3M, A105, LF2, F304, F316, F304L, F316L

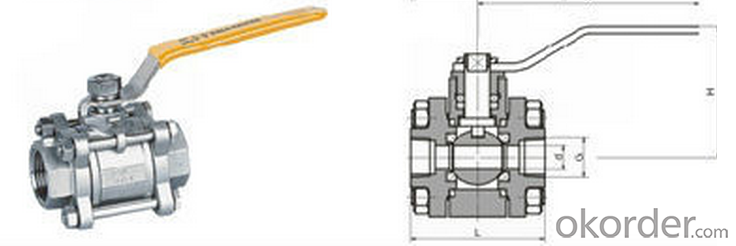

Trunnion Ball Valve

NPS 2"~36"

ANSI CLASS 150~2500

MATERIAL: WCB, LCB, CF8, CF8M, CF3, CF3M, A105, LF2, F304, F316, F304L, F316L

DESIGN STD: API 608, API 6D, BS 5351

FACE TO FACE STD: ASME B16.10, API 6D

END CONNECTION STD: ASME B16.5, ASME B16.47, ASME B16.25

TEST STD: API 598, API 6D, BS 6755

1.Anti-fire safe design.Anti-static device

2.Free leakage of body Sealed construction

3.Double block&bleed.

4.Extension stem.

1.Bow-out proof stem

For the purpose of preventing the stem from flying off resulting in abnormal rising of the inner pressure of valve,shoulder is fixed at the lower part of the stem.In addition,in order to prevent leakage resulting from burnout of packing set of the stem in a fire,thrust bearing is set at the contact position of the shoulder at lower part of the stem and valve body.Thus an inverse seal seat is formed which will prevent leakage and avoid accident.

2.Anti-fire safe design

When the trunnion ball valve be used normally,its sealed by seat and ball surface,seat retainer sealed by O-ring and body,this is soft sealed and reliable sealing.When the seat and O-ring are burnt,the seat retainer and body will be sealed by expanded graphite.Thus act anti-fire safe purpose.

3.Anti-static device

In order to prevent friction among ball,stem and PTFE that generates static electricity which may light the combustibles and explosives that cause an accident,in this ball valve,static-conduction spring is set between the stem and the ball,the stem and the body.Thus static electricity is conducted to ground and system safety is secured.

4.Free leakage of body Sealed construction

The connective position of valve body and bonnet is double sealed by gasket and O-ring,on this base,such factors as fire,high temperature,shock and uneven opening or closing of the torque all can't induce external leakage.

5.Low torque in operation

The self-lubricated bearings are installed at the friction of stem,resulting in wear resistance,fiexibility of operation and low torque.

6. Double block&bleed(DBB)

When ball is full open or close position,the transmitter substance in center cavity of body can be released by drainage and emptying devices.In addition,the over loaded pressure in the center cavity of valve can be released to low pressure end by self relief seat.

7.Emergency sealing

Compound injection holes are designed and compound injection valves are installed at locations of stem/cap and body support of side valve.When sealing of stem or seat is damaged to induce leakage,the compound can be used to do the second time sealing.A concealed check valve is installed in side of each compound injection valve to prevent compound from out flowing due to the action of transmitter substance.The top of the compound injection valve is the connector for fast connection with compound injection gun.

8.Extension stem

For the underground installed valve,the stem can be lengthened and for the convenience of operation the corresponding compound injection nozzle and drainage valve can be extended to the top of valve.

9.Automatic body cavity relief

When the body pressure going up un-normally as the unstable factor,the trunnion ball valve downstream seat will be pushed by un-normally pressure,and the release the unnormal pressure automatically,it doesn't damage to the sealing of upstream seat.

10.Various driving types

The top pad of valve designed according to ISO 5211,which is convenient for connection and exchange of various drivers.The common driving types are manual,electrical,pneumatic and pneumatic/hydraulic.

FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

- Q: What is the service valve?

- I'm talking about the ball valve, because I don't know exactly what you're talking about. I'll explain it to you literally. I don't know, right?

- Q: Manual ball valve type: Class400, 20 ', what does that mean, industrial knowledge?

- The pressure rating of the valve type and American StandardIt's a 20 inch, 400 pound valve20 inch =DN500 (nominal diameter)400 pounds equivalent to nominal pressure PN64 Mpa

- Q: How much pressure DN65 ball valve?

- DN65 represents the nominal diameter of the valve, which is known as "2 and a half inches" of the ball valve!How big is the pressure? The pressure is expressed in PN, and the pressure levels are divided into: PN0.6, PN1.0, PN1.6, PN2.0, PN2.5, etc.

- Q: The hot water pipe ball valve what brand alone?

- Such as the bathroom taps are generally alternating hot and cold water, will be pulled out from the faucet two hoses, and then connected to the wall, embedded in the wall of the interface is angle valve. Because the heating pipe at the corner of the shape of 90 degrees angle, and the ball valve is straight through, so the basic difference between angle valve and spherical valve is that the angle valve exports and imports into 90 degrees right angle. rn usually angle valve mainly plays four roles: rn transfer within rn out nozzle; when the water pressure is too large, can be adjusted in the triangle valve above, turn down; the rn with switch function, if the leading Water Leakage phenomenon, can promptly put the triangle valve off, instead of the total valve closed in the home.

- Q: How can the eccentric hemisphere valve be repaired? What are the things you should pay attention to when installing?

- Standard light valve professionals to answer for you, eccentric semi spherical valve installation methods and precautions:1. Check the cleanliness of the inner cavity of the valve before installation. Make sure the parts are perfect and no foreign objects can be installed.2, ball drive device breaking up, moving and electric way two, can be installed according to user needs, valve installation before test, start and shut two times. When after a period of time, there is a leak valve, adjustable manual and electric driving device for limiting the fastening bolt due to eccentric structure, can compensate for the wear, you must read the "manual and electric drive manual adjustment".3, eccentric axis and valve seat sealing adjustment, must be experienced personnel can be carried out.

- Q: How to distinguish three points copper ball valve, two points copper ball valve

- I. identification methods:Three points, two points mean the specifications of the ball valve, three refers to the diameter of 32, two refers to the diameter of 25.Two, copper ball valve is a brief introduction:The ball valve is mainly used to cut off or connect the line of medium, can also be used to regulate and control fluid, strong shear force between the metal seat seal V type ball valve V type ball core and welding hard alloy, especially suitable for containing fibers, small solid particles and other media.

- Q: Check valve, ball valve, check valve are used in what place, ah?

- The cut-off valve is generally used in the inlet pipe, the outlet valve is generally used in the official website, convenient switch, check valve is to allow water to flow past the water directed, anti back, generally used in vertical pipe, the equivalent of the pump valve

- Q: Is the two piece ball valve in the direction of the pressure pipe?

- First of all, the difference between a ball valve and two chip, three chip ball valve is a ball valve flow, the internal structure of the necking design belongs to the design, the same diameter ball valve products must be smaller than the other two kinds of ball valves flow more.

- Q: Ball valve use?

- The utility model has the action of rotating 90 degrees, and the cock body is a sphere, and has a round through hole or a passage through its axis.

- Q: DN20 pressure 6000PSI, one piece of thread on the threaded, full diameter ball valve body length and flow hole to how much?

- 1, the valve body and the valve cover as a whole bear cavity, must meet the design manual on the minimum wall thickness requirements, at the same time to add corrosion allowance, at the same time calculation, large value as the wall thickness of 2, then according to the height of gate valve diameter, to ensure that the valve in the fully open under the condition, ensure the seal and the valve cover seal gate, so that we can determine the height of

Send your message to us

Forged Flanged End Ball Valve/ Válvula de bola con bridas Fin forjado

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 set

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords