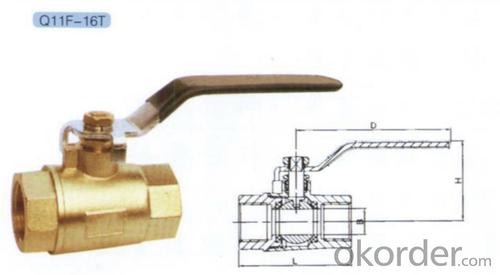

Forged Brass Ball Valve ; Ball Valve ; Brass Ball Valve

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 30000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

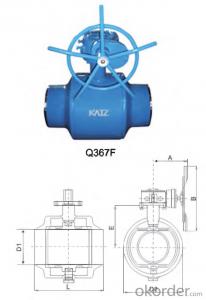

The main copper valves are bronze valves, brass ball valves, copper ball valves, gate valves, check valves, cut-off valves, water nozzles, thermostatic valves, safety valves, Angle valves, exhaust valves, filters, PP-R special valves, aluminum special valves, temperature control valves, pressure reducing valves, pipe joints and other copper valve series more than 1000 varieties. With low price to exchange high quality products, adhere to create more value for customers.

Technical standard

Normal pressure: 1.6MPa

Working medium: cold and hot water , gas fuel , oil , etc.

Working temperature: -20°C≤T≤120°C

Thread standard: ISO228

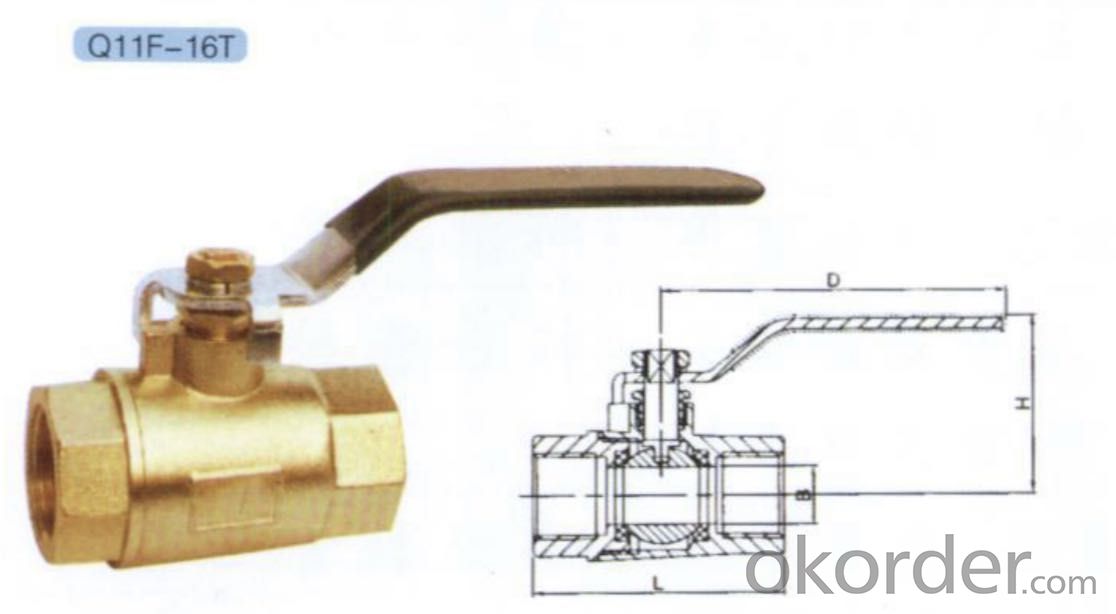

| CODE | DN | SIZE | L | B | H | D |

| 1101 | 15 | 1/2" | 59.5 | 14 | 45 | 91 |

| 1102 | 20 | 3/4" | 64.5 | 19 | 54 | 107 |

| 1103 | 25 | 1" | 71 | 23 | 56 | 107 |

| 1104 | 32 | 1-1/4" | 79 | 30 | 64 | 117 |

| 1105 | 40 | 1-1/2" | 85 | 35 | 73 | 136 |

| 1106 | 50 | 2" | 96.5 | 43 | 83 | 142 |

Please consult customer service before placing an order( in order to confirm with size and material of the relevant product).

- Q: Role of ball valve DN20-Q11F-16

- Q11F ball valve is to control the circulation and cut-off of the pipeline medium.

- Q: Ball valve specifications 1/2 inches corresponding to DN?

- I know that. 1/2 stands for DN15. 3/4 stands for DN20. Ha ha, unfortunately no points

- Q: Manual ball valve type: Class400, 20 ', what does that mean, industrial knowledge?

- The pressure rating of the valve type and American StandardIt's a 20 inch, 400 pound valve20 inch =DN500 (nominal diameter)400 pounds equivalent to nominal pressure PN64 Mpa

- Q: What's the difference between a ball valve and a butterfly valve? Which one has better sealing performance?

- (1) the butterfly valve from the valve body, valve seat, valve plate, valve rod, all parts are a significant drain on the outside, one eye can see; the ball valve is composed of a valve body, the valve core (a round ball), valve rod, valve position is in the valve body inside, the naked eye can see only a part, so the seal the performance of the valve than the butterfly valve well;

- Q: Can the check valve replace the ball valve?

- Check valves are not a substitute for ball valves.Ball valve sealing is superior to all kinds of valves, ball valve according to the implementation of different control mechanisms, can achieve a variety of functions, throttling, regulating, temperature control, headstock, vacuum and so on. These are non-return valves that are not available.The main advantage of the check valve is that it can automatically prevent the backflow of medium and prevent back pressure, water hammer and other effects.

- Q: The two valves are available for the flow of the electromagnetic valve switch, I contact more, found for water solenoid valve are caged water, to repair several times because of impurities or newly installed pipeline with raw materials flowing through the valve, close the valve body when not to rely on Yan, a seepage water tank to diffuse phenomenon!I am looking for a replacement, I think the electric valve should be a good choice, not used to a conclusion.Please use the electric ball valve to talk about friends, or for the two kinds of friends who have an understanding to talk aboutOr there is no better substituteThere seems to control the solenoid valve and electric valve is not the same, the solenoid valve is normally open and closed to control the electric valve is controlled by the trigger (like), if used to replace it, what is the controller?

- I think you should use the solenoid valve is diaphragm type, and not particularly good products, diaphragm solenoid valve in the closed position when the diaphragm is easy to change, resulting in pipe die, or medium impurities caused the pilot hole is blocked, the valve will not move, so the diaphragm solenoid valve. Is there a film guide card member, so that each position of the diaphragm in the correct position, but the pilot hole is not a solution, of course, you can use direct action solenoid valve, such problems are solved. The electric ball valve than the pilot solenoid valve in this respect, but the cost of this fear is much higher, especially the pipe diameter is not so, it does not pay!

- Q: Hello, I would like to ask the household tap water valve selection of stainless steel ball valve or brass ball valve is better, thank you

- I have used two kinds, but stainless steel gate valve is better. Note that it must be made of stainless steel 304. I bought more than 300 yuan a gate valve. Total valve, no way to save money.

- Q: Home tap water valve (ball valve) half open or well open, open half is not love rust live?

- The valve should be fully open the valve open the key is not half open it love rusted because the material inside is processed in general but you will not rust after scouring the semi open water surface changes so that it may be rusty (see you what material is the core surface treatment not original) and this makes serious at bad seat valve sealing effect was lostIn fact, it is necessary to use special control valve to control flow size ~!

- Q: Domestic water pipe ball valve or cut-off valve?

- So, in the regular switch to the place, with the ball valve convenient, in the need to adjust the flow of the place and do not need to switch regularly, with a good cut-off valve.

Send your message to us

Forged Brass Ball Valve ; Ball Valve ; Brass Ball Valve

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 30000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords