Ball Valve ; Fully Welding Ball Valve ; Fully Welding

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 30000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Our ball valves include the floating ball valve, trunnion (mounted) ball valve, metal to metal sealed ball valve, one piece ball valve, V type ball valve, three way ball valve, wafer type ball valve, flanged ends jacketed ball valve, female threaded ball valve, and high pressure forged ball valve.

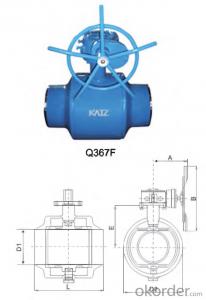

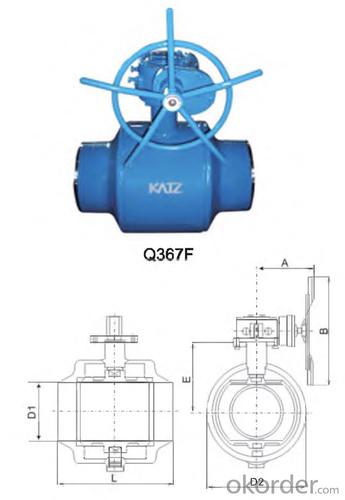

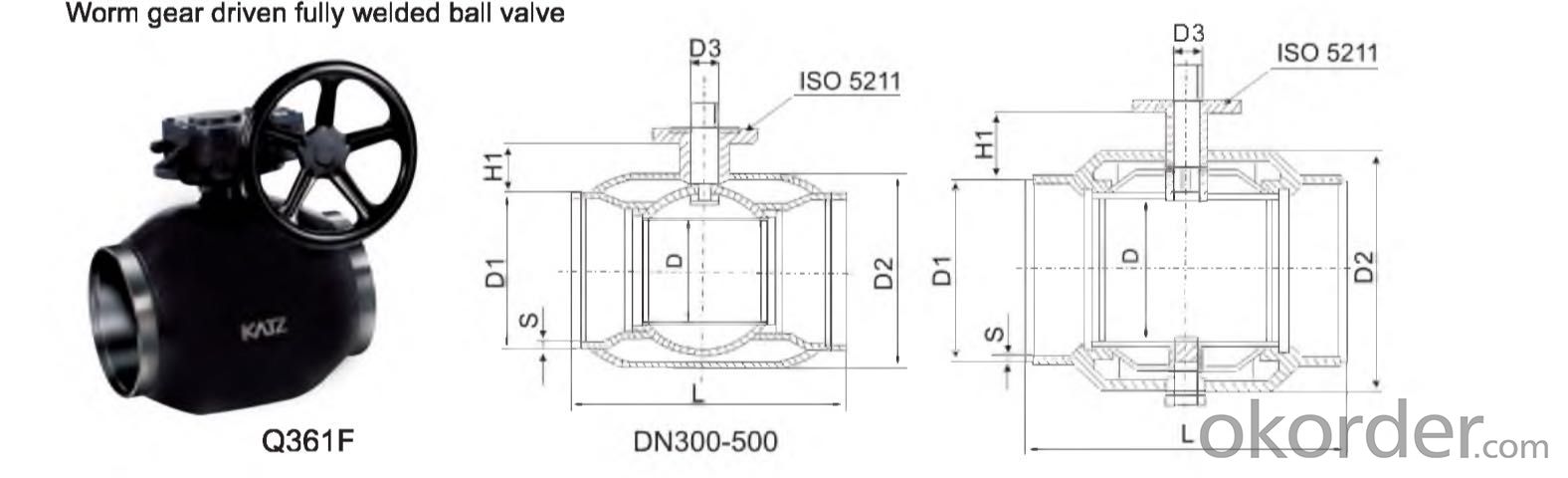

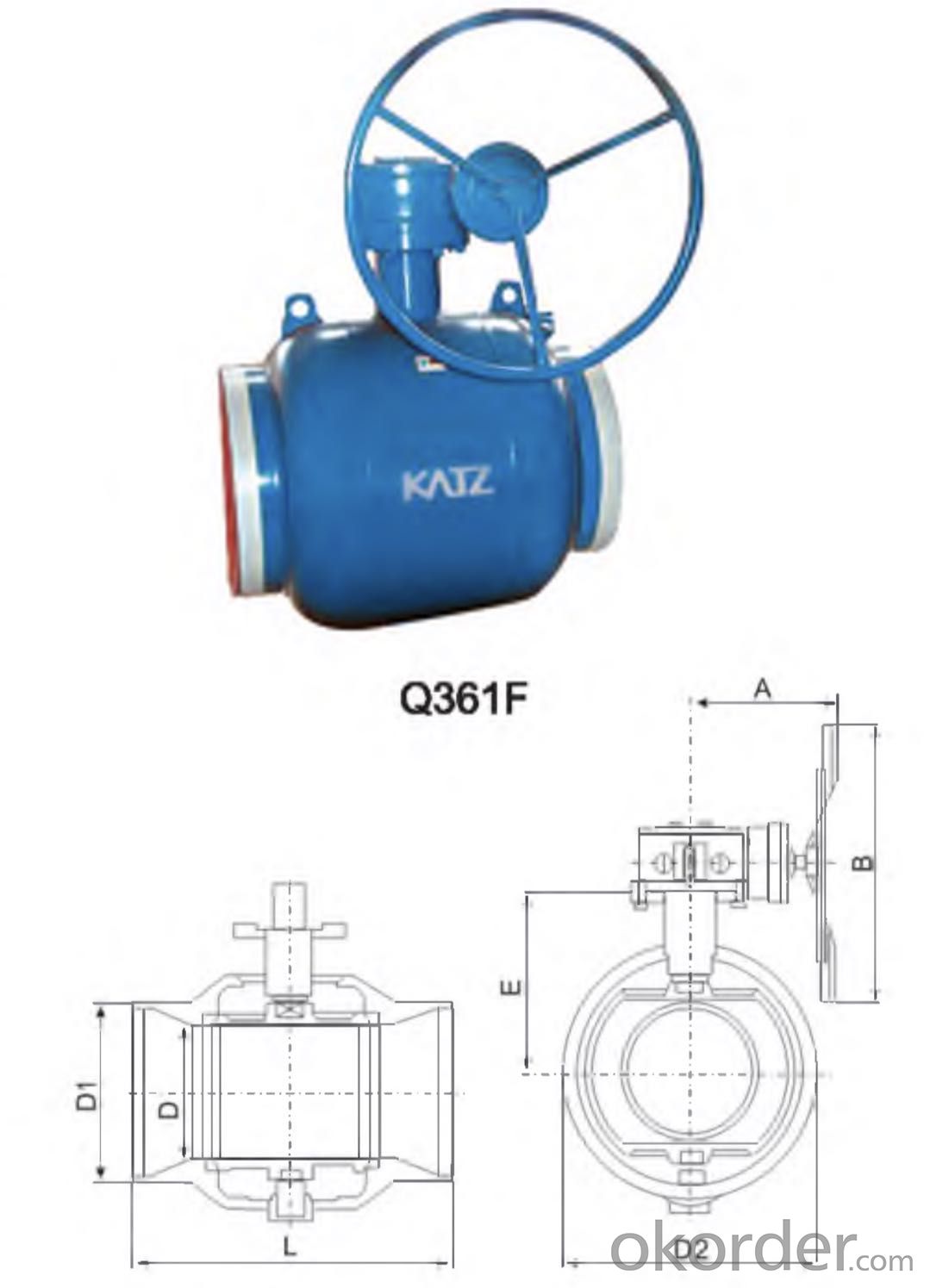

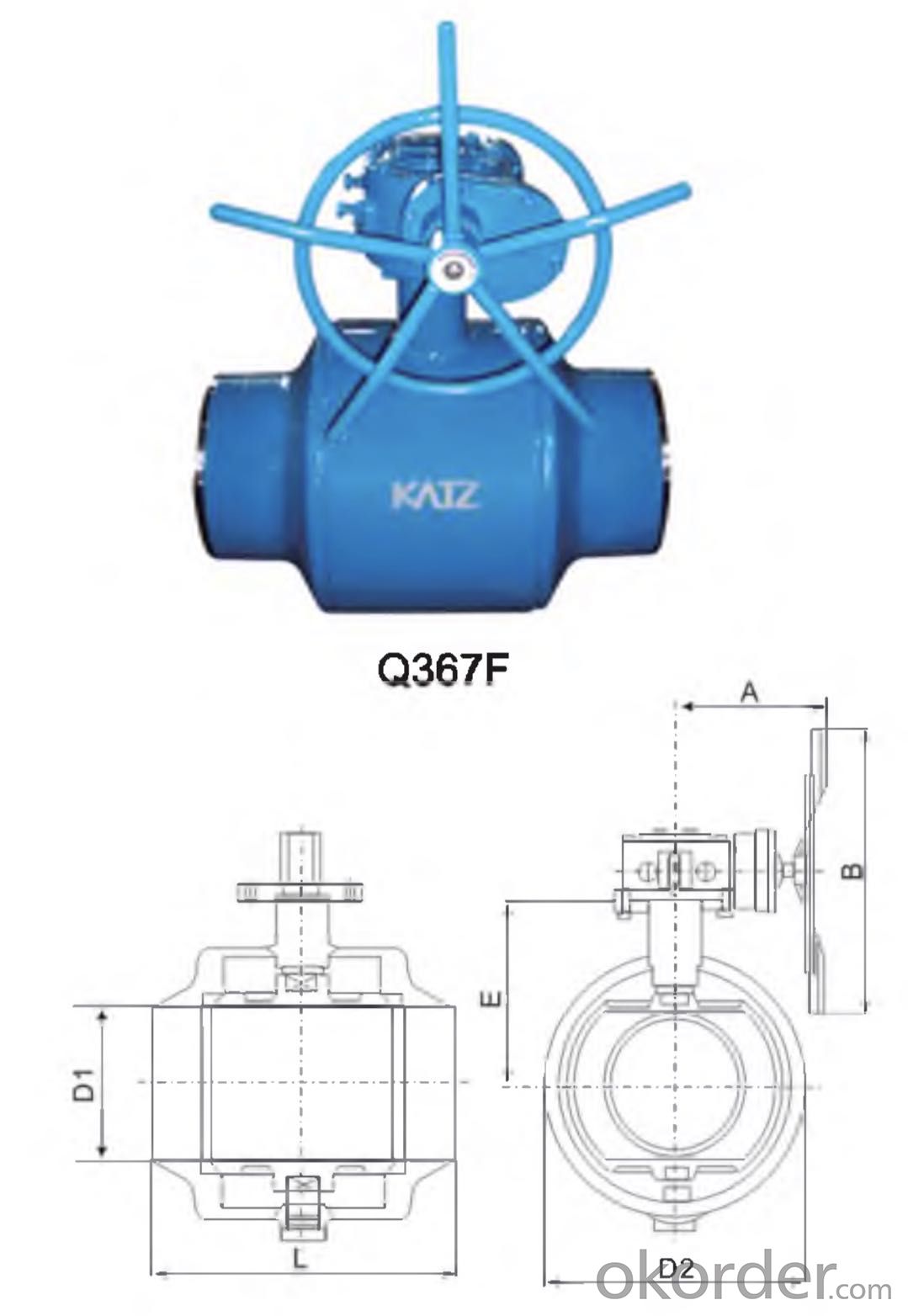

Fully Welding Ball Valve

Main connection size DN200-1400

Meterial of main parts

Parts | Standard Carbon steel | Carbon steel 304 | Carbon steel 316 | Stainless steel 304 | Stainless steel 306 | Low temperature Carbon steel |

Body | A216-WCB ASTM-A105 | A216-WCB ASTM-A105 | A216-WCB ASTM-A105 | A351-CF8 A182-F304 | A351-CF8 A182-F316 | A352-LCB |

Cap | A216-WCB ASTM-A105 | A216-WCB ASTM-A105 | A216-WCB ASTM-A105 | A351-CF8 A182-F304 | A351-CF8 A182-F316 | A352-LCB |

Ball | A216-WCB+HCr ASTM-A105H | A351-CF8 A182-F304 | A351-CF8 A182-F316 | A351-CF8 A182-F304 | A351-CF8 A182-F316 | A352-LCB+HCr LF2+HCr(or Ni) |

Seat | PTFE, PPL, NYLON, Graphite, Impregnaged | |||||

Seat Retainer | A105+HCr A105+Ni | A182-F304

| A182-F316

| A182-F304

| A182-F316

| LF2+HCr |

Spring | 72HC 3YC-7 | 304 3YC-7 | 316 3YC-7 | 304 3YC-7 | 316 3YC-7 | 3YC-7 |

O-ring | NBR | Viton Sl | Viton Sl | Viton Sl | Viton Sl | Sl |

Thrust bearing | 304 or 316 PTFE | |||||

Plain bearing | 304 or 316 PTFE | |||||

Gland | ASTM-A105 | ASTM-A105 | ASTM-A105 | A182-F304 | A182-F316 | A352-LCB CF2 |

Packing | PTFE OR Graphite(fireproof structure) | |||||

Stud | A193-B7 | A193-B7 | A193-B7 | A193-B8 | A194-B8M | A320-L7 |

Nut | A194-2H | A194-2H | A194-2H | A194-8 | A194-8M | A194-4 |

Kay | 45 | 45 | 45 | SOS329 | SOS329 | SOS329 |

Gasket | PTFE OR 304 , 316 Graphite | |||||

Body pressure detection

| ANSI B 16.34 Setion 7.1 | ||

| Valve size NPS | Test pressure | Test time sce |

| | 1:5 times the 100°F | 15s |

| DN65-200 | Rating of ANST Class | 60s |

| >DN250 | Max. operating pressure | 180s |

Detect pressure than the maximun work working pressure valve 1.5 times higher (100F) | ||

| ANSI B 16.34 Setion 7.2 | ||

| Valve size NPS | Test pressure | Test time sce |

| | 1:5 times the 100°F | 15s |

| DN65-200 | Rating of ANST Class | 30s |

| >DN250 | Max. operating pressure | 60s |

Detect pressure than the maximun work working pressure valve 1.5 times higher (100F) | ||

Please consult customer service before placing an order( in order to confirm with size and material of the relevant product).

- Q: All inclusive ball valve and half a bag of the difference between the ball, mainly new manual ball valve

- Only know global valve and hemisphere valve, all inclusive Half pack? I don't seem to have heard of it. Discuss the problem in detail and see if you can explain it.

- Q: What are the advantages and disadvantages of the two functions of the pneumatic ball valve actuator?

- The working principle of the single action mode:When the air pressure from the air intake (2) between the two piston into the cylinder cavity, the two ends of the cylinder piston moves to the separation direction, forcing the ends of the compression spring, both ends of the air chamber air through the air intake (4) discharged, while making two piston rack synchronous drive output shaft (gear) counterclockwise. In the air pressure through the solenoid valve for cylinder piston to move backwards, two to the middle direction in the spring, the middle air cavity air from the air outlet (2) discharged, while making two piston rack (gear) synchronous drives the output shaft to rotate clockwise. (if the piston is mounted in opposite directions and the spring is reset, the output shaft becomes reverse rotating, i.e., single acting reverse type)

- Q: Ball valve 11F, 41F, 11H, 41H

- The ball in, 11F first said the connection mode of "1" threaded connection, second said that the structure of "unit valve 1" straight through, third said "F" said sealing material is PTFE seal;

- Q: Maintenance of PPR pipe ball valve is live or hot melt?

- The ball valve is defined with the ppR/PE hot melt plastic pipe connected with the ball valve hot melt connection, ordinary ball valves generally use the threaded connection or flange connection.Hot melt connection is widely used in PB pipe, PE-RT pipe and other new pipe connections.Hot melt connection has the advantages of simple connection, long service life and easy corrosion.PPR pipes can only be connected by hot melt. There is a dedicated connection PPR tube double union copper ball valve, ball valve is full of copper, on both sides with PPR live tab.Ball valve (in the field of marine engineering and ships should be cut-off valve), standard GB/T21465-2008 "valve terminology" is defined as: "open and close parts (spheres) driven by the stem, and around the axis of the ball valve to rotate the valve movement.". Can also be used to regulate and control fluid, strong shear force between the metal seat seal V type ball valve V type ball core and welding hard alloy, especially suitable for containing fibers, small solid particles and other media. Switch and multi way valve in the pipeline not only can flow, and flow diversion, flexible control of the medium, but also to turn off any channel to the other two channels. This kind of valve should be installed horizontally in the pipeline. In accordance with the way to drive the ball valve is divided into: pneumatic ball valve, electric ball valve, manual ball valve.Ball valve was introduced in 1950s, with the rapid development of science and technology, production process and product structure of continuous improvement, in a short span of 40 years, has rapidly developed into a major valve category. In western developed countries, the use of ball valves is increasing year by year.

- Q: What does "2P" ball valve mean?

- 2P is made up of two parts. The price of 2P is higher than that of 1P, and its performance is good.

- Q: What does 1000WOG mean on a ball screw valve?

- It's also a standard, huh?

- Q: Is the ball valve ball valve?

- One is with an eccentric, hemispherical valve most market means. This eccentric semi ball valve disc shaped like a hemisphere valve valve switch trip also is 90 degrees, but the rotation center of the valve (the valve shaft and the valve seat center (body) or line center) with an eccentric, made after the valve opening immediately from the valve seat, the sealing ball valve and the movement principle is not consistent.

- Q: What does copper ball valve mean by "1/2"?

- This indicates that the caliber of copper ball valve is DN15

Send your message to us

Ball Valve ; Fully Welding Ball Valve ; Fully Welding

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 30000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords