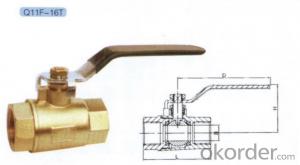

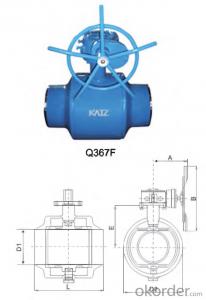

float ball valve ; ball valve ; CLASS150--2500 ball valve

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 30000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Normal pressure or rating | Class 150-Class 2500,JIS I0K - 20K,PN 10 - PN 420 | |||

Normal diameter or bore | NPS 1/2-40,DN6-1000 | |||

Applicable temperature | -196℃-540℃ | |||

Operation type | Manual,worm gear,pneumatic,electric | |||

Standards and specification

| Design& manufacture

| API6D.API608.ASMEBI6.34,ISO5211,ANSI/AWWAC507,BFCI70-2.MSSSP-72,BS5351,B56364,NACE MR0175

| Connection ends

| ASMEBI6.5,ASMEB16.47.API 605,MSS SP-44,ISO 7005-1,JISB2238,BS12627,ASMEBI6.25,ASMEB16.11,BS 12760 |

Face to face dimension | ASMEB16.10,ISO 5752,BS 558, BS12982

| Testing &inspection | API598,API6D,API607,API6FA,BS6755.BS12569,MSS SP-82,MSS SP-6I | |

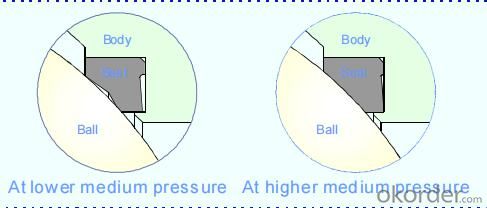

Reliable seat seal

The structure design of elastic sealing ring has been adopted for floating ball valves. This seat design features a bigger sealing pressure ratio between the ring surface and the ball when medium pressure gets lower, where the contacting area is smaller. Thus, the reliable seal is ensured. When the medium pressure gets higher, the contacting area between seat ring and ball becomes bigger as the sealing ring transforms elastically to undertake the bigger force 5 pushed by the medium without any damage.

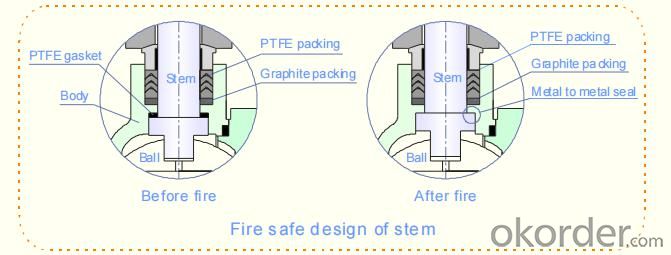

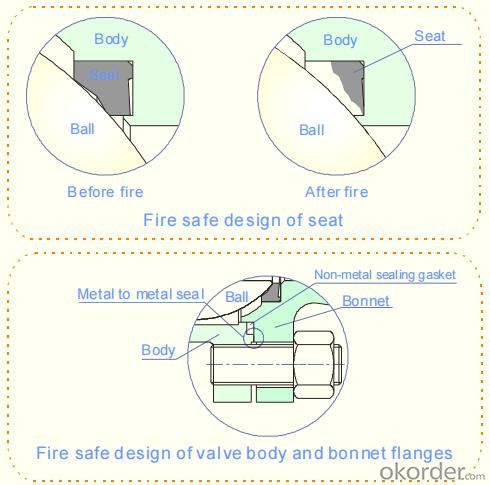

Fire safe design

With the valve heated in a fire application, the non-metal material parts such as seat sealing ring of PTFE, stem back seat gasket, gland packing, and the sealing gasket between body and bonnet might disintegrate or be damaged due to high temperature. Specially designed structure of auxiliary metal to metal seal is provided to effectively prevent both internal and external leakage of the valve. As required by customers, floating ball valves with fire safe design can meet the requirement of API 607, API 6FA, BS6755 and B/T 6899

Reliable stem seal

The blow-out proof design has been adopted for the stem to ensure that even if the pressure in the body cavity is risen accidently and the packing flange becomes invalid, the stem may not be blown out by medium. The stem features the design with a backseat, being assembled from underneath. The sealing force against the backseat gets higher as the medium pressure becomes higher. So the reliable seal of the stem can be assured under variable medium pressure

Anti-static feature

The traditional packing flange design has been improved to be of two piece structure, i.e., being as a packing flange plate and a follower, the latter contacts the flange plate with spherical surface. Thus, the follower remains vertical always, and is lined internally with a PTFE bush to prevent the galling against and friction between the stem, which can also reduce the operation torque of the valve.

The traditional packing flange design has been improved to be of two piece structure, i.e., being as a gland flange and gland, the latter contacts the gland flange with spherical surface. Thus, the gland remains vertical always, and is lined internally with a PTFE bush to prevent the galling against and friction between the stem, which can also reduce the operation torque of the valve.

- Q: Who knows why the ball valve is divided into a piece of ball valve, two pieces of ball valve, three pieces of ball

- There is, of course, a difference,This is according to the structure of the valve body,The difference between them is whether they are easy to disassemble, for example, the three piece of ball valve is easiest to disassemble.

- Q: The working principle of the track type ball valve

- Baidu under the Wuxi East valve, have their contact information, you can consult them

- Q: What does W represent in copper ball valve Q11W-16T?

- According to the provisions of the JB/T 308-2004 valve type programming method:Q== ball valve1== connection: internal thread1== ball valve structure: straight through flowW== sealing surface material: body. That is, the sealing material is the same as the body material-16== pressure rating: 1.6MPaT== body material: copper or copper alloy

- Q: Valve and ball valve is the same thing? Don't know don't speak

- Ball valves belong to a large class of valves, valves include gate valve, butterfly valve, check valve, globe valve, ball valve, trap valve, safety valve, etc. all valves

- Q: What's the difference between a one piece ball valve and a two piece ball valve?

- A piece of ball valve, that is, the principle of Canton style ball valve is to rely on rotary valve to make the valve open or blocked. Valve switch light, small size, can be made large caliber, reliable sealing, simple structure, easy maintenance, sealing surface and spherical often in the closed state, the media can not easily be eroded, widely used in various industries.

- Q: What's English for ball valves?

- Check valve/ball vavle/globe valve (ball valve), there are three kinds of translation, see which you preferFast stainless steel ball valve, ball valve is evolved from the plug valve. It has the same rotation, 90 degrees lifting action, and the difference is that the cock body is a sphere and has a circular through hole or passage through its axis. The ratio of the sphere to the channel opening should be this, i.e., when the ball rotates 90 degrees, the spherical surface should be fully presented at the inlet and outlet, thus truncating the flow. The ball valve only needs to rotate 90 degrees of operation and very small turning moment can close tight. Full equality of the valve cavity for the media to provide a small resistance, through the flow channel. It is generally believed that the ball valve is suitable for direct opening and closing, but the development of the ball valve has been designed to make it throttling and controlling the flow.

- Q: Is the two piece ball valve in the direction of the pressure pipe?

- A piece of ball valve, the current market pressure of most products below 6.4MPA, two piece ball valve about 12.8MPA products are also common, there are 20MPA, three pieces of ball valves are mostly below 6.4MPA. Know the characteristics and shortcomings of these three kinds of ball valves, you can completely choose according to your own needs.

- Q: What is the ball valve Q11F -16 material?

- If sealed, F stands for fluoroplastic. Valve material is not marked in the model!Q stands for ball valvesThe first 1: threaded connection,Second 1: is the ball valve is floating through the ball,F stands for PTFE- PTFE seals16 represents the nominal pressure of the ball valve is 1.6MPa=16 kg

- Q: What's the difference between a medium-sized ball valve and a heavy ball valve?

- It's almost certain that you made an inquiry at the small valve manufacturer in Wenzhou.In fact, the main wall thickness is differentThe so-called heavy, is in accordance with the GB/T12237 Petrochemical ball valve wall thickness to designThe so-called medium-sized, is in accordance with the GB/T12224 steel ball valve wall thickness to design, two wall thickness of some difference, plus a little steal material, sphere do hands and feet, the price can be much lower.There is a light, that is the material does not meet the standards, basically sold to plumbing builders.

- Q: Is the ball valve ball valve?

- The hemisphere valve has two kinds, one is no eccentric, the valve seat is always close the valve, the valve must be made (such as the V type ball valve etc.).

Send your message to us

float ball valve ; ball valve ; CLASS150--2500 ball valve

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 30000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords