Food Level PE Laminated with Craft Paper with Degassing Valve for Packing

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Description of Food Level PE Laminated with Craft Paper with Degassing Valve for Packing:

Food Level PE Laminated with Craft Paper with Degassing Valve for Packing are processing with imported materials ,we have introduced advanced equipment and high manufacturing technology into production lines and we have rich experience in producing plastic bag .can meet your needs by fulfilling your specification in a positive manner .High efficiency and speed are our working style .high quality and competitive price are our pursuit.

Food Level PE Laminated with Craft Paper with Degassing Valve for Packing mainly used in the manufacture of thin films, containers, pipes, wire, wire and cable, and other daily necessities, and can be used as high frequency television, radar and other insulating material. the best choice for all kinds of products ‘packaging.

2. Main Features of Food Level PE Laminated with Craft Paper with Degassing Valve for Packing:

Bottom Sealed Flat PE Unprinted Bags is Polyethylene odorless, non-toxic, feels like wax, has excellent resistance to low temperature performance (minimum temperature is -70 ~ -100 °C), good chemical stability, erosion resistant to most acids (not resistant to oxidizing acid), at room temperature not soluble in common solvents, water absorption, excellent electrical insulation properties.

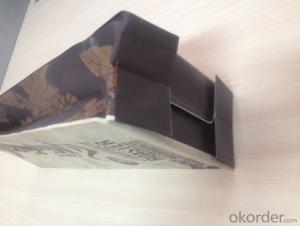

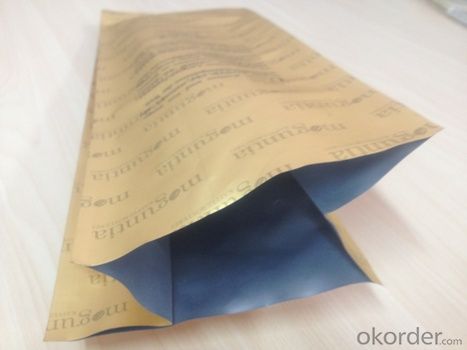

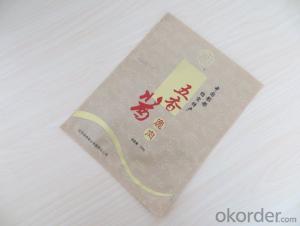

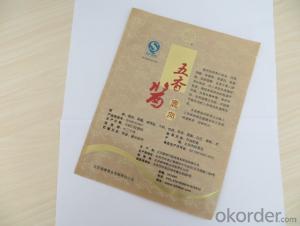

3. Food Level PE Laminated with Craft Paper with Degassing Valve for Packing Images:

4. Food Level PE Laminated with Craft Paper with Degassing Valve for Packing Specification:

1. Material: Laminated material

2.Size:20*750px or Customized

3.Thickness:0.03mm-0.15mm

4.Form:top open bag,ziplock bag, or Unprinted bag

5.FAQ of Food Level PE Laminated with Craft Paper with Degassing Valve for Packing:

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of Plastic packing bags can supply you all kind of packing bags you wanted.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: How do I remove the self-adhesive label affixed to the plastic bag?

- Use the lighter directly on the other side of the metal label to burn for a while. The glue on the label will melt quickly. This method works fastest and works best, but it only works for metals.

- Q: Is the packet in the food package a reducing agent or an oxidizing agent?

- Take active ferric antioxidants as an example;Due to the activity of iron is extremely fine powder, high surface area, the rate of reaction with oxygen is faster. Reduced iron powder. In general, the reaction equation is 4Fe+3O2+6H2O=4Fe (OH) 3, and iron corrosion reactions may also occur.Followed by iron powder particles will adsorption of these smaller food packaging bags in water, the water, in part from within the food, in part from nature. After absorbing most of the excess water, the relative humidity in the food package can be kept constant, which plays a very important role in controlling microbial pollution.

- Q: How are food bags made out?

- Copperplate etching: that is, according to the design confirmation of the food packing bag, the copperplate needed for the food packing press is made. The version is a cylinder, and is a set of not a single root, the specific size, the number of versions, according to the previous package design to determine. One color has to make a copperplate, if there are 5 colors, you have to do 5 copperplate, of course, sometimes can also be common edition.

- Q: How do you determine the 210mm*300mm package and determine its version and length?

- Usually 1 meters, or 1 meters, 2 of the lengthWidth 300,3, leave 40 margin, roll on the design length of 940, version 420 weeks, diameter 133.75

- Q: Do vacuum packing bags have to be vacuum packed?

- Vacuum packaging bags and vacuum packaging machines are related. Vacuum packaging machine not only can complete vacuum extraction, but also can complete heat sealing packaging in vacuum, and ensure vacuum in vacuum bag can meet the requirement.

- Q: What kind of material is the urea packing bag made of?

- Polyethylene (polyethylene, referred to as PE) is a thermoplastic resin made by polymerization of ethylene. Polyethylene odorless, non-toxic, feel waxy, with excellent low-temperature resistance, good chemical stability, resistance to most acid and base corrosion.

- Q: What are the packaging forms of fresh milk?

- The main packaging forms of fresh milk are plastic bags, boxes and bottles. It is closely related to the way of sterilization of fresh milk

- Q: What material is the surface of the packing bag such as instant noodles, pickled mustard tuber, small bread and so on? Why should we add this layer?

- Aluminum filmThe first consideration of food packaging is the barrier properties of packaging materialsBecause barrier property is good, the preservation time is long, the shelf life is long, the quality can guarantee betterAt present, all food packaging materials, aluminum foil barrier is the best (followed by some high polymer plastics, like EVOH, PVDC, etc.)Therefore, the most common, always in the middle of two layers of plastic film, a layer of aluminum foil, to improve barrier,But why not use aluminum foil packaging alone, but also two or more layers of plastic film?,

- Q: Is there any identification on the vacuum package?

- Laser inkjet printer, laser energy generator is the product surface engraved characters.

- Q: Printing solvent for food packing bag

- Smell the smell of solvents. Contact with commonly used solvents, smell, after a long time, the odor of a particular solvent has a rough impression. If the odor of the batch solvent is not pure, it is certain that the purity of the batch solvent is not high or the impurities are more. In addition, the solvent is applied to a clean plastic film to compare its basic odor before and after volatilization, and the tendency of residual solvents can be roughly judged.

Send your message to us

Food Level PE Laminated with Craft Paper with Degassing Valve for Packing

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords