Food Grade CPP or PP Laminated with Craft Paper Bag for Packing

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 pc

- Supply Capability:

- 1000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

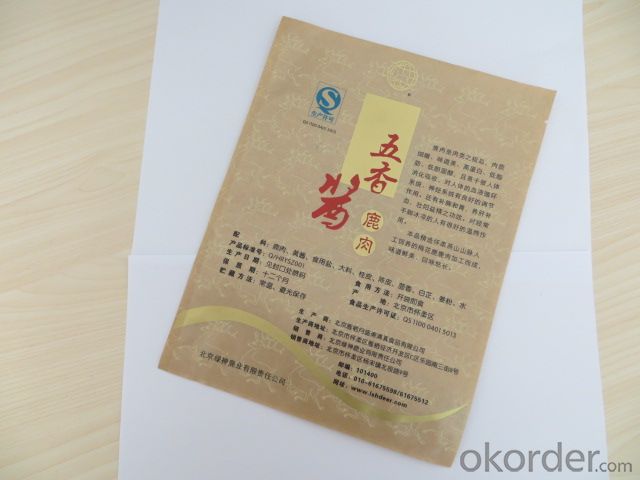

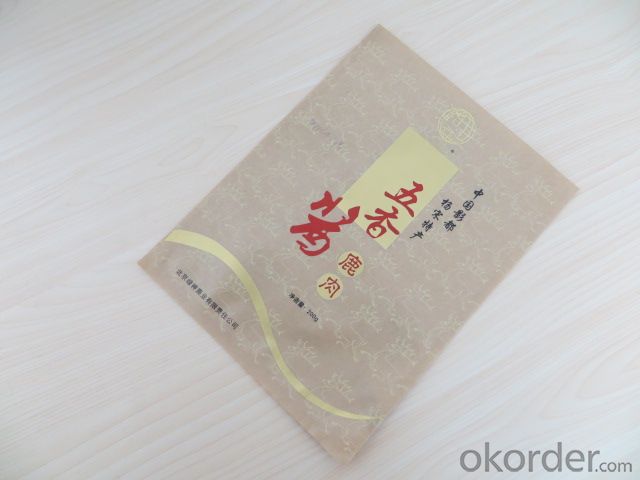

1. Description of Food Grade CPP or PP Laminated with Craft Paper Bag for Packing:

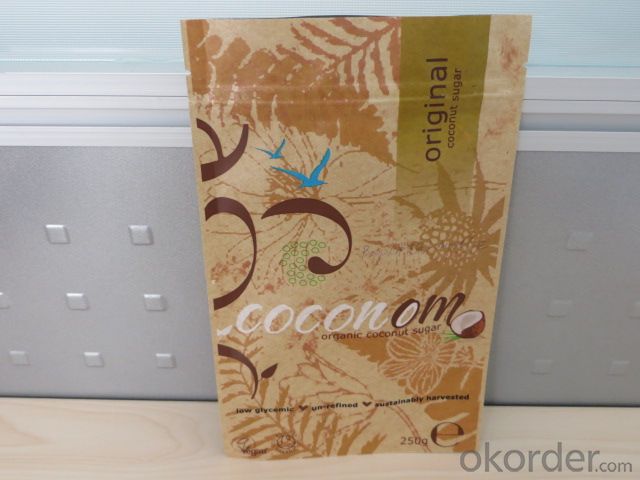

Food Grade CPP or PP Laminated with Craft Paper Bag for Packing are processing with imported materials,we have introduced advanced equipment and high manufacturing technology into production lines and we have rich experience in producing plastic bag .can meet your needs by fulfilling your specification in a positive manner .High efficiency and speed are our working style .high quality and competitive price are our pursuit.

Food Grade CPP or PP Laminated with Craft Paper Bag for Packing mainly used for packing food such as coffee, tea, snack, powder etc.

2. Main Features Food Grade CPP or PP Laminated with Craft Paper Bag for Packing:

Excellent quality control

Experienced facotry produced

SGS passed

3. Food Grade CPP or PP Laminated with Craft Paper Bag for Packing Photos:

4. Food Grade CPP or PP Laminated with Craft Paper Bag for Packing Specification:

1. Material: PE,LDPE,HDPE with Craft paper etc

2.Size:10*10000px or Customized

3.Thickness:10-200um

5.FAQ of Food Grade CPP or PP Laminated with Craft Paper Bag for Packing:

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of Plastic packing bags can supply you all kind of packing bags you wanted.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers. Commonly 7 to 10 working days can be served.

- Q: What products need plastic packing bags?

- Plastic packaging is almost everywhere.

- Q: Express carton packaging, plastic packaging should be how to deal with?

- Express packaging bags can be used as garbage bags, now online shopping people, in addition to vegetables, fruits this difficult to preserve things, a considerable portion of daily necessities are purchased from the internet. However, the excessive packaging of online shopping packages once troubled people. "Online shopping, a clothing is generally at least two layers of packaging, and the first is the clothes factory comes with transparent plastic bags, and there is a layer of express bags attached to the courier."." Some time ago, "double 11", a friend bought three clothes and a set of speakers, these days have gradually arrived, and summed up a total of eight large plastic bags and two cartons.

- Q: What are the requirements of the mark on the cement packing bag?

- Cement gradeCement is divided into strength grade: 1, Portland cement strength grade is divided into 42.5, 42.5R, 52.5, 52.5R, 62.5, 62.5R six levels. 2, ordinary portland cement strength grade is divided into 42.5, 42.5R, 52.5, 52.5R four grades.3. The strength grades of slag Portland cement, volcanic ash Portland cement, fly ash Portland cement and composite Portland cement are divided into 32.5 grades: six, 32.5R, 42.5, 42.5R, 52.5 and 52.5R.

- Q: What are the bags and bags?

- According to the material classification as follows: laser aluminum film, re paper materials, laser transfer paper materials, paper composite materials, aluminum composite materials, plastic composite materials, fabric composite materials.

- Q: What kind of material is the food packing bag in general?

- Now the standard of living has improved, basically the food vacuum packed bag. This will improve the product's shelf life, preservation time is longer, more conducive to product sales.

- Q: What kind of material is the express package on the market now? It's dark in the outer grey.

- The materials used for express bags are generally HD-PE, which can be recycled and can be re packed into bags

- Q: Printing process of packaging bag

- If it is cut into pieces, use a special press for packing bags or screen printing.Screen printing, screen opened relatively simple, but the requirements of the substrate surface is relatively smooth, simple process, relatively low cost, but the adhesion of the ink requirements are relatively high.

- Q: What about the table of nutrition values on food packages?

- serving sizeThe nutrition information displayed in the nutrition information column is based on "every" or "every 100 grams". For foods such as bread, one may be one or two tablets, but for other foods, it may be a little more complicated. A portion that may be only part of the package, or may be part of the normal portion of the meal. Therefore, you need to multiply the actual amount of the food you eat by multiplying the values listed in the nutrition information. 100 grams or 100 milliliters each

- Q: Can the meat with plastic packing bag be pressed directly with a pressure cooker?

- Health performance indicators have two senses, toluene amine, evaporation residue (4% acetic acid), evaporation residue (n-hexane), evaporation residue (65% ethanol), Potassium Permanganate (water consumption), heavy metals (as Pb), decolorization, solvent residue, sterilization indicator.

- Q: What are the types of composite packaging bags?

- Folding small packing bag (or ordinary packing bag)A bag of less weight, usually made of single or double layers. For some special packing bags, it can also be made of multi layers and different materials: the packing range is wide, and the packing can be used in liquid, powder, lump and irregular shape.In these packing bags, the packing bags are suitable for transportation and packing, and the general transport packing bags are suitable for external packing and transportation packing. Small package bags are suitable for inner packing, packing and commercial packing.

Send your message to us

Food Grade CPP or PP Laminated with Craft Paper Bag for Packing

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 pc

- Supply Capability:

- 1000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords