Multilayer PE Laminated with Craft Paper with Bottom Gusset for Packing

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 pc

- Supply Capability:

- 1000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Description of Multilayer PE Laminated with Craft Paper with Bottom Gusset for Packing:

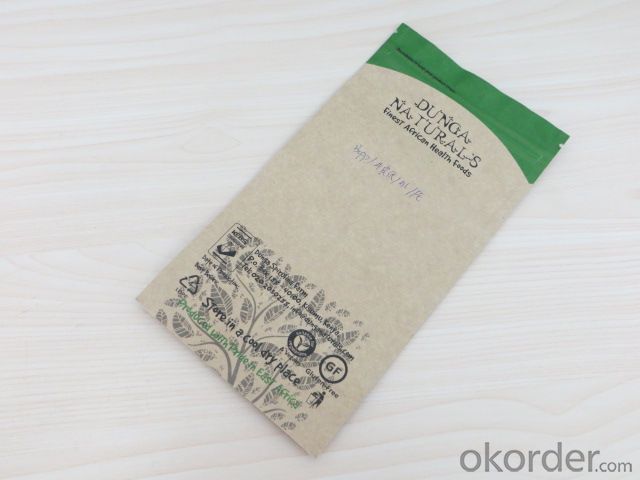

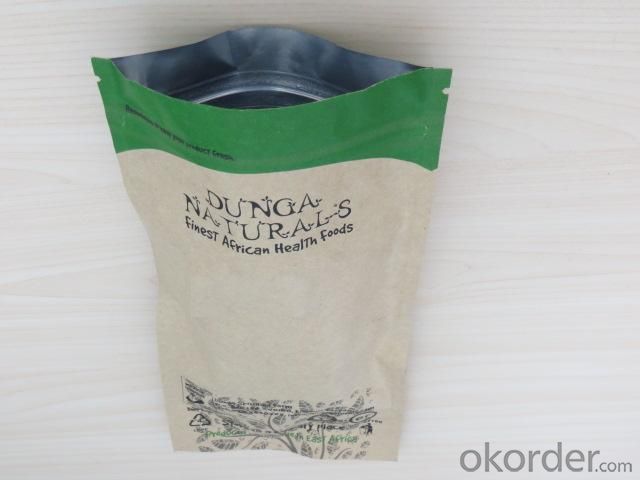

Craft Paper Laminated Packing Bag with Tear North for Packing are processing with imported materials,we have introduced advanced equipment and high manufacturing technology into production lines and we have rich experience in producing plastic bag .can meet your needs by fulfilling your specification in a positive manner .High efficiency and speed are our working style .high quality and competitive price are our pursuit.

Multilayer PE Laminated with Craft Paper with Bottom Gusset for Packing mainly used for packing food such as coffee, tea, snack, powder etc.

2. Main Features Multilayer PE Laminated with Craft Paper with Bottom Gusset for Packing:

Excellent quality control

Experienced facotry produced

SGS passed

3. Multilayer PE Laminated with Craft Paper with Bottom Gusset for Packing Photos:

4. Multilayer PE Laminated with Craft Paper with Bottom Gusset for Packing Specification:

1. Material: PE,LDPE,HDPE with Craft paper etc

2.Size:10*10000px or Customized

3.Thickness:10-200um

5.FAQ of Multilayer PE Laminated with Craft Paper with Bottom Gusset for Packing:

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of Plastic packing bags can supply you all kind of packing bags you wanted.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers. Commonly 7 to 10 working days can be served.

- Q: Express carton packaging, plastic packaging should be how to deal with?

- Most of these packages are thrown away, but this creates environmental pollution and adds to the difficulty of garbage disposal. Environmentally conscious people remove plastic bags and use a knife to remove them from one end of the package, leaving a complete open pocket after opening. Put it in the garbage basket and you can use it as a garbage bag. Full of rubbish, can hold the bag at both ends to the middle or pull sealing, or you can pull a direct sealing tape. This estimate, in general, often online shopping crowd in a week can use two express packaging, "modified" garbage bags, a year down, you can save more than one hundred new garbage bags.

- Q: What is the material for edible fungus stick packing bag?

- HDPE bags, which are not high temperature resistant, can be sterilized at 104 degrees. Over this temperature, the contamination rate of pathogens will be increased.

- Q: What are the requirements of the mark on the cement packing bag?

- Label on cement packing bagCommon C25, C30, C35, C40 label is the cement packaging machine packaging cement mark, specific what label, drawings will generally indicate, general use C25 on the line, the greater the strength higher.

- Q: What kind of material is the food packing bag in general?

- Dry frozen goods, generally cooked with PET/PE., such as high temperature, it is generally nylon composite, CPP, or other composite.

- Q: What kind of material is the express package on the market now? It's dark in the outer grey.

- The materials used for express bags are generally HD-PE, which can be recycled and can be re packed into bags

- Q: What is the difference between LDPE and PE-LD in a package?

- LDPE is a low density polyethylene, environmental protection bag production is one of the raw materials, commonly known as low material, another raw material of HDPE is also called high pressure materials, packaging film, the two materials are mixed according to a certain proportion and then blowing, printing, cutting, packing bag made of,PE-LD is a common environmental protection mark printed on top of the packing bag, which indicates that the manufacturer is using an environmentally-friendly plastic bag.

- Q: Which kind of transparent vacuum packing bag 16 wire and 24 wire?

- The so-called silk is a unit, a trace of =0.01mm, from this point of view, the bag is thicker, the more difficult to leak, so the 24 wire than the 19 wire better.

- Q: What kind of packaging bag does polysilicon use?

- Disposable material into a double-layer polyethylene bag, and then packing bags into the packing box or packaging barrel. Block polysilicon packaging specifications are net 5000g or 10000g per bag.

- Q: How many kinds of packing bags are there in the packaged foods?

- You ask about food plastic packaging, it is generally packaged with composite bags, composite materials, polyethylene (PE), polypropylene, nylon, polyester. These are the main membranes. The film is made of stretch film and blow film. Dry frozen goods, generally cooked with PET/PE., such as high temperature, it is generally nylon, composite CPP, or other composite, many kinds. I am in Dongguan, Humen, food packaging, such as alcoholic peanuts, bags, red dates bags, mask packaging bags, washing powder bags, areca bags, milk powder bags, small fish bags.

- Q: What's bread packing? Polyethylene film, waterproof cellophane, etc.

- Currently, about 90% of the bags are packed in polythene plastic bags.

Send your message to us

Multilayer PE Laminated with Craft Paper with Bottom Gusset for Packing

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 pc

- Supply Capability:

- 1000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords