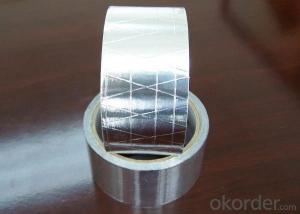

foam tape from china

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

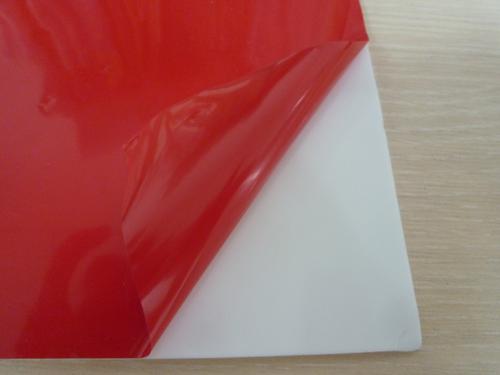

CONSTRUCTION:

Carrier: Acrylic foam

Liner: PE film, red colour.

TYPICAL PHYSICAL PROPERTIES:

Color: Gray

Total Thickness: 1.20mm ± 50 micron

180°Peel Adhesionafter 20 minutes (gf/25mm):3,500

180°Peel Adhesionafter 24 hours (gf/25mm):5,000

TemperatureTolerance :100℃

(24 hoursconditioning at indicated temperature with 100gstatic load)

PACKING:

Jumbo Roll:0.800 x 33m

Packaging:Wrapped with corrugated cardboard.

REMARKS:

1. The data above are typical results and subject to change withoutnotice.

2. Tolerance: Weight and Thickness: ±5%; Width: ±5mm;

Length: Cut Roll & LogRoll ±0.3m, Jumbo Roll ±0.5%.

3. The products should be storedat room temperature and be kept away wet and/or heat source.

4. It is essential, as with allpressure-sensitive tapes, that the surface to which the tape is applied must beclean, dry, and free of grease and oil.

5. The users should take test anddo trial-application on the above products before coming into application so asto witness and ensure suitability for their special purpose and technique.

- Q: How to improve the mobility of rubber material

- When the adhesive is used, appropriate processing temperature is adopted to increase the processing temperature to reduce the viscosity of the rubber, and at the same time, the working pressure is increased appropriately, and the flowability of the rubber compound is increased.

- Q: Rubber and metal have to be sealed before they are too strong

- Different materials and O-ring O-ring compression the change of general material such as NBR, NR, nitrile rubber, natural rubber, chloroprene rubber CR, EPDM three EPDM, HNBR hydrogenated nitrile rubber, silica gel SILICOME SBR Buna, styrene butadiene rubber, SBR, acrylate rubber ACM, compression O-ring or the 20% to calculate. If it is a special material FKM, VITON, PU, FLS silicon fluorine rubber, fluorine rubber, polyurethane, compression of these materials is calculated by 15% o ring.

- Q: Will the rubber ring of the thermos bottle be harmful to the human body?

- No harmThe rubber washer of the thermos bottle comprises a common thermos bottle, an air pressure thermos bottle, an electric pressure bottle and an automatic electrothermal thermos bottle, etc. the rubber sealing washer is directly contacted with the drinking water, and is sealed and heat insulated

- Q: Rubber soaked with hot water will not come out harmful substances?

- Chloroprene rubber chloroprene as the main raw material, made by homopolymerization or copolymerization of small amounts of other. Such as high tensile strength rubber, heat resistance and light resistance, aging resistance and oil resistance properties are superior to natural rubber, styrene butadiene rubber, butadiene rubber. It has a good flame resistance and excellent resistance to burning, its chemical stability is high, water resistance is good

- Q: How are rubber wires processed?

- In the production of rubber products, vulcanization is the last process.Vulcanization is a crosslinking process in which rubber molecules change from linear structure to network structure under certain conditions. Curing methods are cold vulcanization, room temperature vulcanization and heat vulcanizing three kinds. Most rubber products are vulcanized by heat. Hot vulcanizing equipment, vulcanizing pot, flat vulcanizing machine, etc.. Rubber wires and cables are vulcanized by continuous hot air.

- Q: Rubber rolling process for making rubber products

- The rolling process has become a rolling process.The principle of rolling process: using pressure between the calender roller, the material plastic flow deformation, the final film made with the size and geometry of the provisions of section a section, or the rubber covering process in textile or fabric made of metal surface has a certain thickness of the tape section.

- Q: What kinds of vulcanized rubber do you have?

- According to the properties and uses of rubber: in addition to natural rubber, synthetic rubber can be divided into general synthetic rubber, semi general synthetic rubber, special synthetic rubber and special synthetic rubber.

- Q: How can there be a crack in the rubber ring?

- Problems in production:1) formulation design, oil or resin less material or caused by excessive or high temperature, poor liquidity and other reasons!2) when manufacturing, the product appears the hole which the exhaust is not good3) the raw material is too thick during production, and cracks are also caused.

- Q: What is rubber leather?

- The general rubber has good comprehensive properties and is widely used. The main contents are as follows: natural rubber. From the latex of the Hevea tree, the basic chemical composition is cis polyisoprene. Good elasticity, high strength and good comprehensive performance. Isoprene rubber. The full name is cis -1, 4- polyisoprene rubber, a high CIS synthetic rubber made from isoprene, because of its structure and properties similar to natural rubber, it is also called synthetic natural rubber. Styrene butadiene rubber. Referred to as SBR, made by copolymerization of butadiene and styrene. According to the production method, emulsion polymerization, styrene butadiene rubber and solution polymerized styrene butadiene rubber are divided into emulsion polymerization. Its comprehensive properties and chemical stability are good. The br. The full name is cis -1, 4- polybutadiene rubber, referred to as BR, made from butadiene polymerization. And the other than universal rubber, vulcanized butadiene rubber cold resistance, abrasion resistance and excellent elasticity, dynamic load, less heat, good aging resistance, easy and natural rubber, chloroprene rubber, nitrile rubber and etc..

- Q: Rubber products are not allowed to touch oil products, but why can rubber gloves be contacted daily? What's the point?

- Contact every day is not every day inside the bubble, the contact time is short, the impact on rubber is very small.Raw rubber rubber products are: natural rubber, isoprene rubber, nitrile rubber, EPDM rubber, polybutadiene rubber, styrene butadiene rubber, polyurethane rubber, chloroprene rubber, silica gel etc.

Send your message to us

foam tape from china

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords