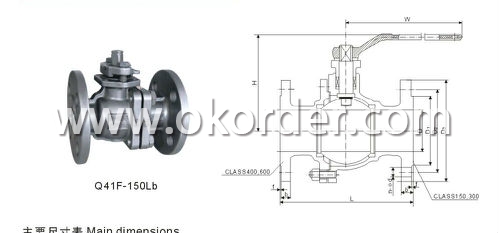

New Ball Valve Metal Industry Left Side Rotating Position Installed Upright 50L-5000L

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 20 sets pc

- Supply Capability:

- To Order pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description of Ball Valve

Standard: Left side big than the Right side after a big flanges , D1 and the reaction kettle connection, the molecules to right flange size, the common denominator for left JB78 flange size, match the reaction kettle 50 L-5000 L.

1. Should stay the valve handle rotating position

2. Not to be used as throttling.

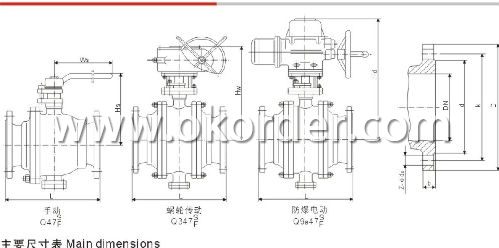

3. The belt transmission's ball valve should be installed upright.

4. Please use the product according to the right, to ensure that the service life of the product, such as unusual situation, that is, please call national unified service hotline 400-666-1929, we will provide you with the high quality post-sale service, give you a satisfactory reply.

- Q: Ball valve specifications 1/2 inches corresponding to DN?

- I know that. 1/2 stands for DN15. 3/4 stands for DN20. Ha ha, unfortunately no points

- Q: The difference between ball valve Q341F and Q347F

- Ball valves Q341F and Q347F are straight through flow, worm drive, flange connection, soft sealing form. Different from Q341F, it is a floating ball structure, and Q347F is a fixed ball structure.Model meaning: Q34 worm gear flange ball valve, 1: floating ball valve;

- Q: To help explain the meaning of the ball valve Q11H-16H, combined with the actual, such valves have wood?

- JB T308-2004 valve model preparation method and "GB1048-2005 pipe element nominal pressure definition and selection", there are various types of valve interpretation:Q11H-16HQ: valve type: (Q) ball valve1: connection form: (1) internal thread1: structure form: (1) through flow channelH: sealing surface or lining material: (H) Cr13 stainless steel16: pressure code: (16) 1.6MPaH: body material: (H) Cr13 stainless steel

- Q: What does the sealing surface of the ball valve stand for HF?

- HF= hard solder material in valves Q347HF, -16C, welded with CoCr or NiCr alloy.

- Q: What's the difference between air valves, butterfly valves and ball valves?

- On the pipeline, mainly from cutting and throttling.Butterfly valve headstock is a disc shaped disc, in the valve body around its own axis of rotation, so as to achieve the purpose of opening or closing or regulation.Ball valve: opening and closing parts (sphere) driven by the stem, and around the square ball valve for the axis of the rotating valve.Shanghai Guardian valve, all types of valves are industry-leading.

- Q: What are the CF8 and CF3M marks on the stainless steel ball valves?

- CF8 stands for 304 material, and CF3M stands for 316L.Stainless steel ball valves only need to rotate 90 degrees of operation and small rotating torque can be closed tight. Full equality of the valve cavity for the media to provide a small resistance, through the flow channel. The main features of the valve itself is compact, easy operation and maintenance, stainless steel ball valve can be used to control air, water, steam, all kinds of corrosive media, mud, oil, metals and radioactive liquid media and other types of fluid flow. Ball valve body can be integrated, or can be combination. This kind of valve should be installed horizontally in the pipeline. Stainless steel ball valve classification: stainless steel pneumatic ball valve, stainless steel electric ball valve, stainless steel manual ball valve. Stainless steel ball valve is divided into 304316321 stainless steel ball valve.The working principle of the ball valve is to rotate the spool to make the valve unblocked or blocked. Valve switch light, small size, can be made large caliber, reliable sealing, simple structure, easy maintenance, sealing surface and spherical often in the closed state, the media can not easily be eroded, widely used in various industries.

- Q: What does "41H" mean in the ball valve Q41H-16?

- Q- ball valve;4- flange connection;1- through flow channel; (structural form)H-Cr13 stainless steel; (material)16- nominal pressure; (1.6Mpa)Body material: WCB, A105This is manual, and the valve body is WCB.

- Q: What's the meaning of the ball valve bore 14 "x 12"?

- Should refer to imports 14 inches, export 12 inches, this kind needs to make to order, at present domestic possibly not yet.

- Q: Daily maintenance of ball valve

- The new parts need to be cleaned before assemblingThe assembly should have metal fragments, fiber, fat is not allowed (except the requirement to use) dust and other impurities, foreign matter contamination, adhesion or remain in part into the cavity on the surface or, if the packing is micro discharge, to lock the stem nut.Note: do not lock too tight, usually lock 1/4 circle to 1 laps, the leak will stop.(A) disassemblyMake the valve in a half open position, flush and remove dangerous substances that may exist inside and outside the valve body.Close the ball valve, remove the connecting bolts and nuts on both sides of the flange, and then remove the valve completely from the line.In order to remove the drive - actuator, a connecting bracket, lock washer, stem nut, butterfly spring, glam, wear plates, valve stem packing.Remove the body cap connecting bolts and nuts, separate the valve cover from the valve body and take off the valve cover washer.Make sure the ball is in the "off" position, which can be easily removed from the valve body and then removed from the valve seat.A hole in the body downward nudge stem until completely removed, and then remove the packing ring and the O.Caution: Please operate carefully to avoid galling, stem surfaces and body packing box seals.B) reassembleCleaning and inspection of the parts removed, it is strongly recommended to use spare parts package replacement valve seat and valve cover, gaskets and other seals.Assemble in reverse order of disassembly.Cross the locking flange bolts with the specified torque.Lock the stem nut with the specified torque.

- Q: Our factory has part of the ball valve in the direction of movement and normal ball valve is the opposite direction: anti clockwise for the turn off, clockwise. Excuse me, what's the reason for this?Excuse me, is this because the valve body installs the reason of the contrary or the reason, the ball valve is thus designed?Are there any positive and negative points when the ball valve is installed?

- Ordinary ball valve is the reverse turn off, the general ball valve without direction requirements. Each kind has the direction request, generally has the arrow or the nameplate explanation on the valve body.

1. Manufacturer Overview

| Location | Zhejiang, China |

| Year Established | 2004 |

| Annual Output Value | Below US$1 Million |

| Main Markets | North America; South America; MidEast; Africa; Oceania; East Asia; Europe; Japan; Southeast Asia |

| Company Certifications | ISO 9001:2008; CE; API-6D |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Wenzhou |

| Export Percentage | 1% - 10% |

| No.of Employees in Trade Department | 101-200 People |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | 8000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | High; Average |

Send your message to us

New Ball Valve Metal Industry Left Side Rotating Position Installed Upright 50L-5000L

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 20 sets pc

- Supply Capability:

- To Order pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches