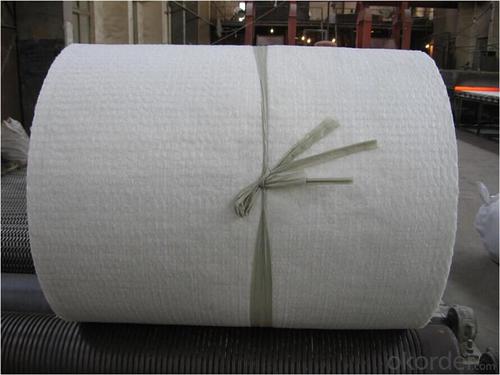

Fireproof insulation ceramic fiber blanket

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 100 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Grade: | COM (Common) | Application: | Refractory | Thickness: | 6-50mm |

| Width: | 610/1220mm | Length: | 7200mm | Chemical Composition: | SIO2 AL2O3 |

| Ultimate Strength (≥ MPa): | 0.04 | Working Temperature: | 1260 | Fiber Diameter: | 2-3um |

| Shrinkage (1800 ℉, 3h): | < -3 | Thermal Conductivity: | 0.055-0.180(W.k.m.) | Density (kg/m³ ): | 128 |

| Model Number: | insulation ceramic fiber blanket | Brand Name: | Place of Origin: | China (Mainland) | |

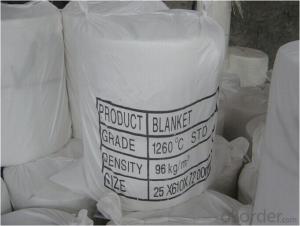

| color: | pure white | Density: | 64/80/96/128/160kg/m3 | Certificates: | ISO9001:2000; ISO14001:1996 |

| Package: | carton or woven bag | working temp: | 1260-1430C | Name: | Insulation ceramic fiber blanket |

Packaging & Delivery

| Packaging Detail: | Carton box outside and plastic bag inside or negotiable according to customer's need |

| Delivery Detail: | 10~15 days after signing contract and receiving advanced payment |

Specifications

1.insulation ceramic fiber blanket

2.High tensile

3.Low slag ball content

4.MSDS, ISO9001:2008

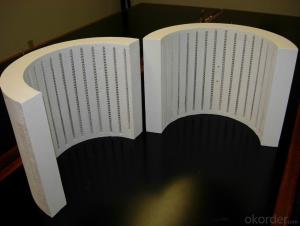

Insulation Ceramic Fiber Blanket

Product Description

insulation ceramic fiber blanket is ideal thermal insulation material, fireproof material and sound-absorbing material. Ceramic fiber blanket has even texture and smooth surface.

Technical data of Insulation Ceramic Fiber Blanket

Grade | Common | Standard | High Pure | High Aluminum | Zirconium | |

Max. Temperature (℃) | 1100 | 1260 | 1260 | 1360 | 1450 | |

Working Temperature (℃) | < 1000 | 1150 | 1180 | 1260 | 1350 | |

Color | Pure White | Pure white | Pure white | Pure white | Pure white | |

Density (kg/ m3) | 96/128/160 | 96/128/160 | 96/128/160 | 128/160 | 128/160 | |

Shrinkage on heating (%) (24 hours, density as 128/m3) | -4 | -3 | -3 | -3 | -3 | |

Thermal conductivity by mean temp. (w/m.k) (density as 128kg/m3) | 0.09(400℃) | 0.09(400℃) | 0.09(400℃) 0.16(800℃) | 0.12(600℃) | 0.16(800℃) | |

Tensile strength (MPa) | 0.04 | 0.04 | 0.04 | 0.04 | 0.04 | |

Chemical composition (%) | AL2O3 | 44 | 46 | 47-49 | 52-55 | 39-40 |

AL2O3+SiO2 | 96 | 97 | 99 | 99 | - | |

AL2O3+SiO2+ZrO2 | - | - | - | - | 99 | |

ZrO2 | - | - | - | - | 15-17 | |

Fe2O3 | <1.2 | <1.0 | 0.2 | 0.2 | 0.2 | |

Na2O+K2O | ≤0.5 | ≤0.5 | 0.2 | 0.2 | 0.2 | |

Size (mm) | 15000×610/1220×10 14400×610/1220×12.5 7200 ×610/1220×20 7200 ×610/1220×25 5000 ×610/1220×30 4500 ×610/1220×40 3600 ×610/1220×50 (Other sizes and shapes on request. ) | |||||

Package | Carton or woven bag | |||||

Certifications | ISO9001:2008 MSDS | |||||

Good Quality We have a senior R&D team and strict QC |

Fast Delivery Time A large scale of production lines ensure the fast production |

Free Sample Free sample will be sent to you, but you should pay freight cost |

- Q: Slag ball content of ceramic fiber material?

- Effect of slag ball content on ceramic fiber materialSlag ball content ceramic fiber products is an important factor that affects the bulk density. Slag ball density in 2800 ~ 3200kg/m fand, excessive slag ball content fiber products, comprehensive energy-saving performance will reduce the ceramic fiber blanket, ceramic fiber module of ceramic fiber products, and damage the interests of users.

- Q: Who can help me introduce the principle of vacuum forming of ceramic fiber board? Thank you very much.

- Features: excellent chemical stability, excellent thermal stability, excellent tensile strength, low thermal conductivity, low thermal capacity, excellent sound absorption and noise reduction performance. Typical applications: aerospace, steel, petrochemical high temperature insulation; military road insulation; electrical components insulation; fire protection; high temperature gasket; modules, folding blocks of raw materials. Three. Ceramic fiber felt products: ceramic fiber vacuum forming felt is made of ceramic fiber cotton produced by resistance furnace injection molding. It is processed by vacuum forming process. It is a lightweight, flexible refractory fiber insulation material, made of a combination of high purity refractory oxides and organic binders. In addition to the excellent properties of bulk ceramic fiber cotton, the ceramic fiber vacuum forming felt has good strength and elasticity, and is a versatile product. Product characteristics: high strength, long service life; low heat capacity, low heat conductivity; non brittle material, toughness; size precision, good flatness; cutting easy installation, convenient construction; excellent anti erosion properties; continuous production, fiber distribution, stable performance; excellent acoustic noise performance.

- Q: What is ceramic fiber?

- 1, ceramic fiber is a fibrous lightweight refractory material, has the advantages of light weight, high temperature resistance, good thermal stability, low thermal conductivity, specific heat and resistance to mechanical vibration, and thus in machinery, metallurgy, petroleum, ceramics, glass, electronics and other industries have been widely used.2, ceramic fiber products is a good refractory. The utility model has the advantages of light weight, high temperature resistance, small heat capacity, good insulation and heat insulation performance, good high-temperature heat insulation performance, no toxicity, etc..3, light quality, good heat insulation performance, good thermal stability, good chemical stability, easy processing and convenient construction. It is neither wear-resistant nor collision resistant, can not resist the erosion of high-speed airflow, and can not resist the erosion of molten slag.

- Q: What ceramic fiber profiled products are needed in steel mills? What's the name?

- Ceramic fiber and nano heat insulation board are used for heat insulation, and in the steel plant are generally used for ladle, tundish insulation, and now can also be made of nano insulation products special-shaped products.

- Q: Refractory ceramics and other refractory materials manufacturing is a big industry?

- For example: petrochemical, steel, fertilizer, casting, glass, cement and other industries.

- Q: What brand of ceramic fiber products is best?

- Ceramic fiber, ceramic fiber, aluminum silicate fiber, its variety of products, the main products include ceramic fiber blanket (aluminum silicate blanket), ceramic fiber module (aluminum silicate module), ceramic fiber board (aluminum silicate), ceramic fiber paper (paper / aluminum silicate refractory fibre paper), ceramics (aluminum silicate fiber felt mat), ceramic fiber, ceramic fiber, ceramic fiber rope etc..The quality of the above products can be highlighted from two aspects:1, large-scale production2, the application of advanced technology3, brand awareness of the high and low

- Q: The characteristics of ceramic fiber paper

- There are a lot of ceramic fiber paper called, some people call the fire-resistant fiber paper, insulation paper, aluminum silicate fiber paper, ceramic fiber paper is made from high purity ceramic fiber production, used in the field of high temperature insulation, advanced production technology makes the fiber distribution is very uniform, density and volume of paper can be strictly controlled.There are three kinds of ceramic fiber paper: standard ceramic fiber paper, high alumina ceramic fiber paper and zirconium ceramic fiber paperCeramic fiber paper features: low heat capacity, ground heat conductivity, good electrical insulation performance, excellent mechanical processing performance, easy to cut, strong and tear resistance; high flexibility; low slag ball content

- Q: Can a series of ceramic fiber products be used in combination?

- Ceramic fiber products is referred to, including ceramic fiber, ceramic fiber blanket, ceramic fiber, ceramic fiber module, ceramic fiber paper, ceramic fiber folded block, ceramic fiber blanket, ceramic fiber, special-shaped pieces of Castable Ceramic fiber, ceramic fiber spray coating, ceramic fiber cloth, ceramic fiber, ceramic fiber rope dozens of products, ceramic fiber products are combined to use in the process of using.

- Q: How to choose the right ceramic fiber and aluminum silicate products?

- 3, according to the thickness of insulation to chooseThere are a lot of insulation thickness of furnace is fixed, the insulation thickness of conventional material is inappropriate, only according to the heat flow calculation formula to calculate the appropriate level of insulation material is the most scientific, the conventional case raised to two of the product can be registered.

- Q: At present, the field of ceramic fiber, what is the latest development of technology or products?

- The latest technology -- Research and development of ceramic fiber composite. HLGX ceramic fiber composite insulation board is a new super insulation material produced by semi dry process, which is the first in the world. The difference between it and imported aerogel composite insulation board is reinforced fiber changes (replaced by glass fiber ceramic fiber), change of substrate and adiabatic main material ratio, and the addition of other nano additives. The promotion point of innovation -- resistance to temperature liftingHighest 800 C to 1000 C, long-term working temperature shrinkage rate decreased from 3% down to 2%, there is a big boost for high temperature applications, only the production process is complicated, the cost is still high.

Send your message to us

Fireproof insulation ceramic fiber blanket

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 100 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords