Furnace and oven heat resistant ceramic fiber blanket

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 100 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Grade: | COM (Common) | Application: | Liners Of Industrial Furnace | Thickness: | 6-60mm |

| Width: | 610/1220mm | Length: | 3.6m/7.2m/14.64m | Chemical Composition: | Al2O3: 46% |

| Ultimate Strength (≥ MPa): | 0.08-0.12Mpa | Fiber Diameter: | 3-5um | Thermal Conductivity: | 0.09-0.16w(m.k) |

| Brand Name: | Place of Origin: | (Mainland) | density: | 64-160kg/m3 | |

| certification: | BV,ISO9001:2000, Rohs, SGS, | working temperature: | 1050C | sample: | aviable |

Packaging & Delivery

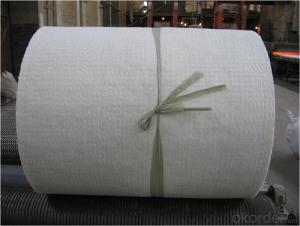

| Packaging Detail: | . Plastic bag inside and woven bag out side, 620rolls/1x40HQ 2. Plastic bag inside and carton out side, 525ctns/1x40HQ |

| Delivery Detail: | 15-20DAYS AFTER RECEIVING PAYMENT |

Specifications

Specifications

1. Type:STD, HP, HA, HZ

2. Density:64-160kg/m3

3. Service temp:1050-1350C

4. ISO9001:2000, Rohs report

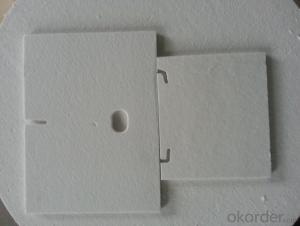

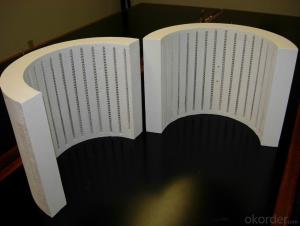

Ceramic Fiber Blanket is a great energy saving product because of its superior insulating properties and advantages of low heat storage and complete resistance to thermal shock. It is widely used as industrial insulation, high temperature insulation and in a variety of heat processing applications. Ceramic fiber blanket is produced from high strength spun ceramic fibers and is needled to provide exceptional handling or construction strength. KT Refractories stocks large amounts of High quality Ceramic Fiber Blanket in Houston TX: 2300°F or 2600°F Ceramic Fiber Blanket with different width or densities, or thickness. Related Ceramic Fiber Blanket products are also available: ceramic fiber Strips, ceramic fiber modules, ceramic fiber paper, ceramic fiber bulk,ceramic fiber textiles, and ceramic fiber board etc.

New! Ceramic Fiber Strip in stock -- 2300°F 8# 1" thick, 4" or 6" wide Ceramic Fiber Strips in 300" length. Ceramic Fiber Strips are packed in a box of 6 or 4 respectively and they are cut out of Ceramic Fiber Blanket. Ceramic Fiber Strips are soft and commonly used as gasket material.Ceramic Fiber Strip are cut off from Ceramic Fiber Blanket, therefor it has all the insulating advantages and excellert features of ceramic fiber blanket.

Ceramic Fiber Blanket's excellent features and typical applications of Ceramic Fiber Blanket are:

Excellent chemical corrosion-resistant performance without being influenced by oil and water

Excellent construction and tensile strength

Contains no bonding agent, great white color and flat even surface, easy to cut

Very low shrinkage

Ceramic Fiber Blanket for REFINING and PETROCHEMICAL

Reformer and pyrolysis lining

Tube seals, gaskets and expansion joints

High temperature pipe, duct and turbine insulation

Crude oil heater linings

Ceramic Fiber Blanket for STEEL INDUSTRY

Heat treating and annealing furnaces

Furnace door linings and seals

Soaking pit covers and seals

Furnace hot face repairs

Reheating furnace and ladle covers

Ceramic Fiber Blanket for POWER GENERATION

Boiler insulation and boiler doors

Reusable turbine covers

Expansion seals/pipe coverings

Ceramic Fiber Blanket for CERAMIC INDUSTRY

Kiln car insulation and seals

Continuous and batch kilns

Ceramic Fiber Blanket for OTHER INDUSTRY FIELDS

Insulation of commercial dryers and ovens

Veneer over existing refractory

Stress relieving insulation and fire protection

Glass furnace crown insulation

Product information

Item | Ceramic Fiber Blanket |

Type of Blanket | Standard,High Pure, High Aluminum ,Al-Zirconium,Zirconium. |

Classification Temperature | 1260°C,1360°C,1430°C |

Applications | •The industry kiln, heating device, high temperature pipe lining •Power boiler, gas turbine and heat and nuclear power insulation •Chemical industrial high temperature equipment and heating equipment lining •Fireproof and heat insulation for high building •High-grade household appliances thermal insulation device •High temperature filtration etc |

Features | •Low thermal conductivity, low thermal capacity •Excellent thermal stability and good resistance to heat shock •Excellent tensile strength •Good anti-stripping performance •Good Sound-absorbing performance •Non-brittleness material, good flexibility •Excellent machining performance •Resistance to wind and erosion, long service life •Excellent heat insulation, fire prevention, sound absorption performance |

Payment Terms | L/C, D/A, D/P, T/T, |

Delivery Time | Within 15 days after received the deposit. |

Technical data

Type | Common | Standard | High Purity | High Aluminium | Zirconia | |

Classification temperature (°C) | 1100 | 1260 | 1260 | 1360 | 1400 | |

Working Temperature (°C) | < 1000 | 1050 | 1100 | 1260 | 1350 | |

Color | White | Pure white | Pure white | Pure white | Pure white | |

Density (kg/m3) | 96/128/160 | 96/128/160 | 96/128/160 | 128/160 | 128/160 | |

Shrinkage on heating (%) (24 hours, density as 128/m3) | -4 (1000°C) | -3 (1000°C) | -3 (1100°C) | -3 (1250°C) | -3 (1350°C) | |

Thermal conductivity by different temperature (w/m.k) (density as 128kg/m3) | 0.09(400°C) 0.16(800°C) | 0.09(400°C) 0.16(800°C) | 0.09(400°C) 0.16(800°C) 0.20(1000°C) | 0.12(600°C) 0.20(1000°C) | 0.16(800°C) 0.20(1000°C) | |

Tensile strength (MPa) (density as 128kg/m3) | 0.04 | 0.04 | 0.04 | 0.04 | 0.04 | |

Chemical composition (%) | AL2O3 | 44 | 46 | 47-49 | 52-55 | 39-40 |

AL2O3+SiO2 | 96 | 97 | 99 | 99 | - | |

AL2O3+SiO2+ZrO2 | - | - | - | - | 99 | |

ZrO2 | - | - | - | - | 15-17 | |

Fe2O3 | <1.2 | <1.0 | 0.2 | 0.2 | 0.2 | |

Na2O+K2O | ≤0.5 | ≤0.5 | 0.2 | 0.2 | 0.2 | |

Size (mm) | 14640/7200/3600×1220/610×6-50; Other sizes can be available. | |||||

Ceramic fiber blanket Excellent thermal stability Excellent chemistry quality Resistance to burning Low thermal conductivity Low heat storage Good obstructing voice and mechanism strength Low shrinkage Good springiness for fibersConvenient producing and installing

Ceramic fiber mat Application: Joint sealing and filling insulation (kiln car, pipeline, kiln door and so on) Fiber composite (for example: grinding parcel) Internal and external lining for industrial furnace Structure refractory and sponging sounds Materials for hot filtration Raw materials for further producing

HOT PRODUCT:

Calcium Silicate Insulation Board 1000C

Calcium Silicate Pipe/2014 New Product/ Best Quality With Good Sale

Brands Blanket Heat Insulation blanket Thermal Insulation Refractory Ceramic Fiber Blanket

Wall Heat Insulation Rock Wool Board

Foam Glass Sound/ Fire Proof /Heat Insulation Materials

Ceramic fiber products specialized manufacturer in China Type:1050C/1260C/1360C/1430C Density:96/128/160kg/m3 Thicknes:6-50mm

Production Technology of ceramic fiber products:

Common grade are made of hard chamotte clay, which are meltdown in resistance furnaces and processed by blowing or swinging technology.

The high purity and high aluminum ones are made of composite materials of pure alumina and silica powder, which are meltdown in resistance furnaces and processed by blowing or swinging technology.

Zirconium ones are made of composite materials of high purity alumina, silica powder and zircon sands, which are meltdown in resistance furnaces and processed by blowing or swinging technology.

Working temperature of ceramic fiber material:

Depending on the material working conditions, heat source types and environmental conditions.

Technical Features of ceramic fiber products:

Low thermal conductivity, low heat storage;

Excellent thermal stability and thermal shock resistance;

Excellent tensile strength;

Excellent thermal insulation, fire-proof and sound absorption;

Typical Application of ceramic fiber products:

Industrial furnace, heating devices, high temperature pipe wall linings;

High tempeture boilers, steam turbine and Nuclear power thermal insulation;

Chemical industrial high-temperature reaction equipment and heating equipment wall linings;

High building fireproof and thermal insulation;

Furnace door and roof thermal insulation;

High temperature filter materials

- Q: Slag ball content of ceramic fiber material?

- 2800 ~ 3200kg/m the data of fand, right?Chasing the answerThis value is 2800 ~ 3200kg/m fand slag ball density, not ceramic fiber density

- Q: Which expert to help, urgent?! Thank you, 20Is the type of refractory material, shaped like cotton mattress like, but not really cotton, is some ore and some artificial material is made into the refractory with high temperature of one thousand degrees, will not change the kind of.

- Aluminium silicate refractory fiber cotton custom HS Code: 68061000.9068129900 refractory fiber cotton (containing asbestos)84748090 aluminium silicate refractory fiber cotton and its product line equipment

- Q: Who can help me introduce the principle of vacuum forming of ceramic fiber board? Thank you very much.

- Product Description: with stable performance, long fiber and tensile strength, less slag ball, high thermal stability, white color and so on. The classification temperature is 1050-1600 degrees centigrade. It is the preferred material for the production of fiber textiles. It is also an ideal material for sealing, filling and heat insulation in high temperature environment. Features: low thermal conductivity, low thermal capacity, excellent chemical stability, corrosion resistance, excellent sound absorption property, excellent thermal stability. Typical applications: raw materials for industrial ceramic fiber wet products; raw materials for ceramic fiber unshaped products; high temperature kilns, heating devices, wall linings, gap filling materials, etc.. Two, ceramic fiber blanket Product Description: white color, regular size, set fire, heat insulation, insulation in one. Free from any binding agent. In the neutral and oxidizing atmosphere, the tensile strength, toughness and fiber structure can be maintained for long term use. The temperature is 950-1400 centigrade.

- Q: What is ceramic fiber paper?

- Ji'nan Huolong ceramic fiber paper is made from high purity ultrafine ceramic fiber cotton by dispersing agent evenly dispersed, high temperature binder and a dilution ratio of the mixed, heated by microwave drying was prepared.

- Q: What ceramic fiber profiled products are needed in steel mills? What's the name?

- Ceramic fiber and nano heat insulation board are used for heat insulation, and in the steel plant are generally used for ladle, tundish insulation, and now can also be made of nano insulation products special-shaped products.

- Q: Refractory ceramics and other refractory materials manufacturing is a big industry?

- For example: petrochemical, steel, fertilizer, casting, glass, cement and other industries.

- Q: The characteristics of ceramic fiber paper

- Ceramic fiber paper, aluminum silicate fiber paper, also called refractory fiber paper.Classification of ceramic fiber paper:Standard ceramic fiber paper HLGX-236High alumina ceramic fiber paper HLGX-436Ceramic fiber paper containing zirconium HLGX-536

- Q: ceramic fiber

- Advantages of ceramic fiberRefractory ceramic fiber material is a lightweight and efficient thermal insulation material. It has the following advantages over traditional heat insulation materials:Ceramic fiber as lining, low volume density: ceramic fiber lining than light heat insulation brick lining light more than 75%, lighter than light castable lining light 90% to 95%. If using fiber lining, it can greatly reduce the steel structure load and prolong the service life of the furnace.The heat capacity (heat storage capacity) of ceramic fiber lining is low: the heat capacity of ceramic fiber is only about l/10 of light heat resistant lining and light castable lining, and the heat capacity of lining material is proportional to the weight of lining. Low heat capacity means the furnace in the reciprocating operation absorb less heat and heating speed, greatly reducing the operational control of the temperature in energy consumption, especially for heating furnace and furnace, furnace shutdown has obvious energy saving effect.Ceramic fiber lining: low thermal conductivity of ceramic fiber lining in the average temperature of 400 degrees, the thermal conductivity is less than 0.1w/mk, the average 600 degrees less than 0.l5 w/mk, average 1000 degrees less than 0.25w/mk, about l/8 as a lightweight clay brick, lightweight refractory lining l/10, adiabatic effect.The construction of ceramic fiber lining is simple: no expansion joints are needed during construction, and the construction personnel can be started after the basic training. The technical factors of construction have little influence on the insulation effect of the lining. Ji'nan Sheng Yang

- Q: How to choose the right ceramic fiber and aluminum silicate products?

- When choosing ceramic fiber, aluminum silicate fiber products,1, according to the use of temperature to choose,1050, ordinary ceramic fiber, aluminum silicate fiber, suitable for 850 degrees Celsius temperature insulation1260 standard ceramic fiber aluminum silicate fiber, suitable for 1000 degrees Celsius temperature insulation1260 high purity ceramic fiber, aluminum silicate fiber, suitable for 1100 degrees Celsius temperature insulation1400 high alumina ceramic fiber aluminum silicate fiber is suitable for 1200 degrees Celsius temperature1400, zirconium containing ceramic fiber, aluminum silicate fiber, suitable for 1280 degrees Celsius temperature insulation

- Q: At present, the field of ceramic fiber, what is the latest development of technology or products?

- Soluble ceramic fiber is a new product and biodegradable. Beijing Fei Pufu

Send your message to us

Furnace and oven heat resistant ceramic fiber blanket

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 100 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords