Glass Wool Fireproof Refractory Insulation made of Glass Fiber, Plain Glass Fiber, and Carbon Fiber Cloth

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t

- Supply Capability:

- 500 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

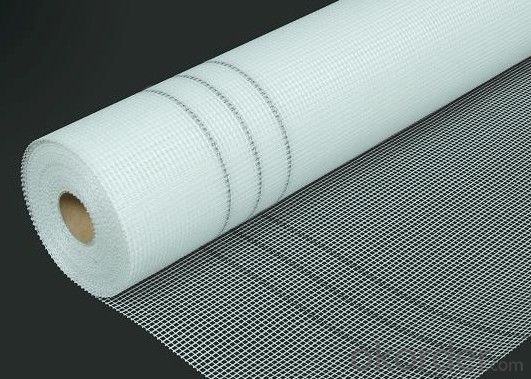

| Place of Origin: | Hebei, China (Mainland) | Brand Name: | cnbm | Weight: | 1000g per sqm |

| Width: | 100cm~150cm | Weave Type: | Plain Woven | Alkali Content: | Alkali Free |

Packaging & Delivery

| Packaging Details: | carton package,with kraft paper and stretch film inside |

| Delivery Detail: | upon your order quantity |

Plain glass fiber and carbon fiber hybrid cloth 12k-100cm1000g

Wovened by carbon fiber and glass fiber, mainly used for Shoe sole.

Glass Fiber Fabric is an new composite material, which has the excellent merit such as anti-burns, anti-corrosion, heat-isolation, minimum elongated shrinkage, high intensity; this new material product has already covered many domains such as sports and leisure field , especial in surfboards , Boats and yachts, etc.

Carbon Fiber is high strength and extremely light weight. It is the most commonly used composite fabric with applications in all areas of industry, such as household applications, machines ,aerospace,spaceflight and other high-tech applications. Aosheng has super woven technology and exact molding technics and equipments, so we can produce full Carbon series products to meet all kinds of process requirement on composite materials.

- Q: How about the sound insulation performance of glass wool felts?

- Fix the glass wool in the wall with pegs, then cover it with plywood, after laying up with wooden surface, nail the wood again.

- Q: What are the advantages and disadvantages of centrifugal glass wool?

- Centrifugal glass wool board is fiber product, so human body will be allergic, whose temperature endurance is 400 degrees with good thermal insulation effect, mainly used in buildings and underground pipes.

- Q: Can Kunnai glass wool board and sound absorption blankets be used to maintain sound insulation in hotel floor? Can it decrease half of the noise? How to install?

- No estimate half, but still able to play a sound effect

- Q: How to convert thickness if the heat insulation effects of glass wool board and rubber and plastic board is the same?

- It can be converted according to the experience The two products can be compared with each other the contrast is relatively poor (depending on use) five six thick glass wool use 2 rubber and plastic board Pay attention to the problem of usage and the environment

- Q: How is the insulation property of glass wool color steel?plate?

- It has poor insualtion property but good firepoof property. Rock wool insualtion board is recommended.

- Q: Are there any hazards during the glass wool construction?

- Glass wool and asbestos are completely two different products. The raw material of glass wool is glass. Protection work must be prepared during construction.

- Q: What is the price of glass wool felt ?

- Different thickness and density of the glass wool, different price. Generally it is a few dollars one square meter. Glass wool and rock wool are divided into: board, pipe, roll mat. This depends on how much K (density) you need. Now the factory price of glass wool is around 2500yuan per ton.

- Q: What is the fire rating of fireproof sound-insulating glass wool board?

- Generally we do not use A1, A2 but A class, which is non-combustible levels. A level is higher than the B level. B-level is divided into B1and B2. B1 stands for flame retardant type and B2 combustible type. rock wool and glass wool both rates A class. secondly, Rockwool can endure high temperature of 800 degrees, glass wool 450 degrees.bulk density of rockwool is heavier than that of glass wool. And glass wool has better waterproof performance.

- Q: How about the thermal insulation performance of glass wool?

- Rubber and plastic insulation materials and centrifugal glass wool boards have their own advantages. Rubber and plastic is a foam material with easy installation, soft and delicate, is mainly used in the air conditioner. Centrifugal glass wool board is fiber products, some people will be allergic to it. It can resist 400 degrees, and has a good thermal insulation performance, is mainly used in buildings and underground pipelines. They are approved thermal insulation construction products.

- Q: What are the standards of glass wool board?

- The national standard of rock wool board for exterior wall in construction is GB / T25975-2010, rock wool board for curtain walls in construction is GB / T25975-2005, and industrial rock wool board is GB / T11835-2007. The above-mentioned criteria are the standards of using rock wool products in various industries! Rock wool board is specifically designed and produced for exterior thermal insulation thin plastering system. It can be applied to the cosntruction of concrete or brick based buildings or thermal insulation or energy-saving of the exterior walls of he existing buildings; Wherein rock wool belt for thermal insulation of exterior walls can also serves as fire buffer zone and it can be used with thermal insulation material whose combustion performance is below A level to improve the fireproof function of the exterior walls of the building.

Send your message to us

Glass Wool Fireproof Refractory Insulation made of Glass Fiber, Plain Glass Fiber, and Carbon Fiber Cloth

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t

- Supply Capability:

- 500 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords