Fireclay Brick for Furnace Insulation - Refractory Brick Price

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description:

Fireclay Insulation Refractory Brick for Furnace Price Of Refractory Brick is a kind of insulation material adopting organic matter as ignition loss substance in order to increase the porosity of refractory, which has such advantages as high porosity, small volume density, good insulation effect, high mechanical intensity, small thermal conductivity and long service life. For various industrial kilns & furnaces, it is a kind of essential refractory for energy saving and temperature preservation.

This series of Fireclay Insulation Refractory Brick for Furnace Price Of Refractory Brick are made of selected high alumina bauxite, kaolin clay, hollow microsphere as the mian material.By shaping at high pressure and sintering at high temperature

Product Applications:

1. Furances of glass,coke oven,electric and so on

2.Furnaces of metallurgy industry, heat treatment furnace

3. Furnaces of chemical industry and construction industry.

Main Product Features:

1. Low porosity,High bulk density.

2. High Cold Crushing strength.

3. High refractoriness under load.

Product Specifications:

1.With 55% Al2O3 min;

2. Refractoriness: 1750C min;

3.For steelmaking furnaces;

4.ISO 9001 Certificate;

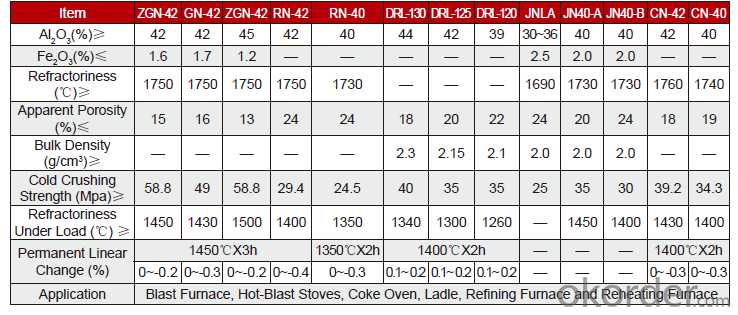

Technical data:

Q1 What’s the transport method?

A1 FCL delivery goods with wooden pallet or wooden case by sea; If LCL delivery, must with wooden case; Sometimes need open top, flat rack or bulk cargo.

Q2 What’s the required payment term?

A2 Generally 30% TT as the prepayment, 70% TT before delivery. If need, 100% Irrevocable Letter of Credit or negotiation.

Q3 Which country are our products exported to?

A3 Apart from entire Chinese market, the US, Russia, Japan, Korea, Australia and some Southeast Asian Nations.

- Q: The stove which made of refractory bricks and fireclays will produce cracks after being used. How to solve this problem?

- The use of low expansion materials will be better. But as for the stove, the appearance of crack is attributed to the selected materials or the environment. And when the temperature is not high, there still seems to be crack, so through expansion joint reservation, not allowing itself to crack

- Q: Whether yellow dextrin is used in refractory bricks?

- The production of refractory bricks needs yellow dextrin as bonded materials.

- Q: General used refractory brick T-20 / T-39/ T-206 specifications and dimension

- No T-206 model (we produce the clay) T-20 and T-39 are the size of 230*length, 113* width and 65/45 thickness, T-20 is a vertical arch brick and T-39 is horizontal arch brick.

- Q: Would you please tell me how to use the simple method to identify shale brick, clay brick?

- Is the shale as raw material for high temperature baked bricks using shale and coal gangue, clay brick not dense surface, general clay brick for load-bearing structure, relatively thick, single shape; shale brick shapes, shapes with holes, in non bearing structure.

- Q: Can red bricks be burned in tunnel kiln which used to burn refractory brick?

- The raw material determines the production process; the output determines the kiln type; the technology determines the quality and quantity.

- Q: What raw materials are used for making refractory bricks

- That is silicon aluminum refractory brick/, it can be divided into five types:thermal insulation refractory brick, alkaline series refractory brick, refractory brick containing zirconium, carbonaceous refractory brick/. Refractory bricks are divided according to the ingredient of refractory. Refractory bricks are generally made from refractory clay (kaolin) or other refractory materials.

- Q: What is the difference between clay brick, glazed tile and brick?

- The whole brick is made of rock debris and is pressed by high pressure. After the surface is polished, the hardness can be compared with the stone, the water absorption rate is lower, and the abrasion resistance is good. The surface of the brick is not glazed, and the material of the front and the back is consistent with the color and lustre, hence the name. Although there are seepage flower, brick and other species, but relatively speaking, its color than non glazed tile. Most of the antiskid bricks are all kinds of bricks.

- Q: What are the sizes and sizes of clay bricks?

- According to the compressive strength (Newton / square millimeter, N/mm2) the size is divided into MU30, MU25, MU20, MU15, MU10, MU7.5, these 6 intensity levels.The bigger the size, the stronger the compressive strength.

- Q: Can thick steel plate be used instead of the furnace inside the refractory brick?

- It depends on the temperature. The steel plate is a kind of heat conduction material which hasn't heat insulation, which should be based on the working environment.

- Q: The service life of the refractory brick of the intermediate frequency electric furnace, how long is the replacement period.

- There is no standard. As long as the induction coil can be fixed and furnace lining can be built, the service life will be different. Replace it if it's broken, and there is no problem to take it apart. Buy a backup. And the textures of refractory brick are not the same in different places.

Send your message to us

Fireclay Brick for Furnace Insulation - Refractory Brick Price

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords