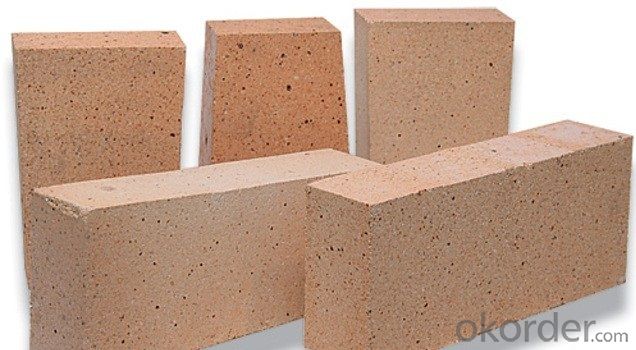

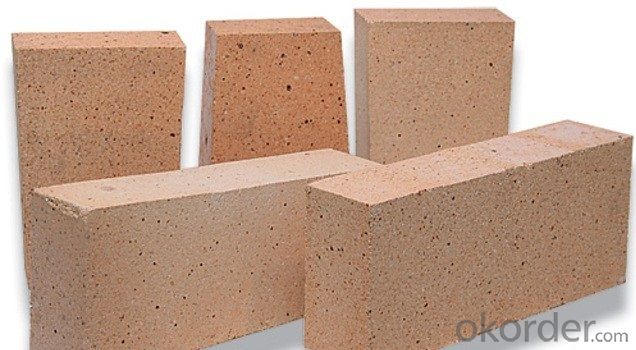

Fireclay Brick - Lightweight Insulating Fire Brick

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 pc

- Supply Capability:

- 100000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Place of Origin: | Henan, China (Mainland) | Shape: | Brick | SiO2 Content (%): | 0 |

| Al2O3 Content (%): | 0 | MgO Content (%): | 0 | CaO Content (%): | 0 |

| Refractoriness (Degree): | Common (1580°< Refractoriness< 1770°) | CrO Content (%): | 0 | SiC Content (%): | 0 |

| Model Number: | BB004 | Brand Name: | Beixing/ BRCC | color: | red |

| condition: | new | weight: | 0.5kg | max. service tem.: | 1350°c |

| application: | industry furnance | After-sales Service Provided: | yes | Warranty: | 1 year |

| shape: | brick | materials: | clay & hollow sphere |

Packaging & Delivery

| Packaging Details: | Normally,1000kg or1100kg into a pallet,each piece is isolated by good padpaper,or bubble film,or foam board,etc..Outside,with tight shrink film wrapping around and anti collision bars&big fiber board in sides. The customized package is available. |

| Delivery Detail: | 1 week |

Product Description

Specifications

1.Insulating firebrick

2. Low density

3. Low thermal conductivity

4. Good thermal insulation performance

Technical parameter

Type (item) | GG0.8 | GG0.7 | GG0.6 | GG0.5 | GG0.4 |

Density g/cm3≤ | 0.8 | 0.7

| 0.6 | 0.5 | 0.4 |

Compressive strength Mpa≥ | 2.5 | 2.0 | 1.0 | 0.8 | 0.5 |

thermal conductivity 350°C±25 °C W/m.k

| 0.21 | 0.20 | 0.17 | 0.16 | 0.13 |

linear change on reheating≤2%×8h Lab Temperature °C | 900 | ||||

Definition:

It is a kind of the light weight refractory products which contains the alumina content range from 10% to 15%.

Production process:

Ingredients and water mixed together made the plastic pug or slurry, then Extruded-Form or moulding by casting, dry, and firing in the 1250-1350°Coxidizing atmosphere.

Application:

Mainly used as thermal insulating layer without the liquid melt touched or gas pickling in the constructing the various industry furnaces.

- Q: refractory bricks of fireclay

- According to the preparation process, it can be divided into bricks, high alumina brick, magnesia brickand so on, such as refractory clay brick, and ordinary brick; according to the shape and size, it can be divided into standard brick and silica?brick, it can withstand all kinds of physical and chemical changes and mechanical action at high temperature; silica?brick can be used as high-temperature building materials and structural material to build kiln and kinds of thermal equipments. Refractory material and fused brick with a certain shape and size are called refractory?brick for short.

- Q: What are the main components of refractory bricks

- Mainly is magnesium oxide, sodium silicate as a binder

- Q: What is the material of refractory brick used in the high temperature zone of the kiln?

- The ordinary generally use clay high alumious fireclay brick. GB/T 3994-2005 insulating refractory brick. What with good material is high-grade thermal insulation refractory brick. GB/T 3995-2006, high alumina thermal insulation refractory brick , model A13, is made of aluminium oxide, A13 50U, senior heat insulatio brick B5

- Q: can the refractory sand be used to make refractory bricks?

- No...

- Q: does the furnace wall use refractory bricks to keep the heat? Or use the insulation material to keep heat ?

- if use the rock wool or aluminum silicate, the furnace arch and furnace wall of biomass boiler all use refractory brick, and outside the furnace wall there is a layer of insulation material, some is perlite coal-fired boiler

- Q: How much fireclay is needed per cube refractory bricks?

- Normal refractory bricks need to use 70-80kg refractory mud each cubic . In fact, this can be calculated, because the volume of refractory bricks and refractory mud density can be measured. Of course, here is an important point, that is the size of the brick seam, 1mm brick seam and 3mm is significantly different. Sichuan brand refractory mud has many kinds, like high aluminum, clay, corundum, magnesia, insulation and so on, the dosage is different.

- Q: What is the advantage for ceramic fiber material compared with refractory brick?

- Heat capacity; excellent thermal shock resistance, good chemical stability, bearing sudden cooling and heating, without oven heating and cooling ,high speed, energy saving, is 1/8 of refractory brick, construction is simple. ceramic fiber materials and refractory brick belong to refractory insulation materials; low thermal conductivity: Low bulk density, ceramic fiber material is a new type of lightweight thermal insulation material, is one of the 10 points of lightweight refractory brick,

- Q: The making process of clay brick

- Clay brick materials, cheap, durable, and fire prevention, heat insulation, sound insulation, moisture absorption and other advantages, is widely used in civil engineering. Waste brick can also be used as aggregate of concrete. In order to improve the shortcomings of ordinary clay bricks, such as small, self important and waste of soil, they are developing in the direction of light weight, high strength, hollow and big blocks. In a proper ratio of lime sand brick and quartz sand, sand or fine sand, the ground, Kazumi Wa, semi dry pressing and autoclaved curing and. The fly ash brick is made of fly ash as main raw material and mixed with cement material such as coal gangue, stone powder or clay. It is made up of batching, molding, drying and roasting. It can make full use of industrial waste residue and save fuel.

- Q: Do cement kiln refractory bricks have quality guarantee period? can them still be used for a long time's pile?

- They of course can be used. The plant will produce some bricks for standby application in advance, so they put for a period of time is completely no problem

- Q: Can you direct the clay brick walls embryo

- Times are different, where there is no modern calcination process. With glutinous rice water in the soil, but glue well, but there is no comparable with cement and other building materials. Not long, can not withstand weathering.

Send your message to us

Fireclay Brick - Lightweight Insulating Fire Brick

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 pc

- Supply Capability:

- 100000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords