Anchor Brick, Refractory Brick, Fireclay Brick for Ceramics Tunnel Kiln

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description:

Refracotory brick is a refractory ceramic material used in lining furnaces, kilns, fireboxes, and fireplaces.

We provide high quality Refractory Fire Bricks that are used on wide range in the various industries like Cement, Glass and Steel. Refractory Fire Bricks are provided as per the quantity and specifications required by the customers. We provide an extensive range of Refractory Fire Bricks at reasonable prices that depend upon the quantity ordered.

Fire Clay Brick Features:

1. Good thermal stability, low thermal conductivity, good insulation performance.

2. Low bulk density, good integrity, high mechanical strength.

3. Good thermal shock stability, good resistance to abrasion and corrosion.

4. Good volume stability at high temperature.

5. Low water absorption rate, low creeping rate.

6. Natural clay products, could be shaped freely, non-radioactive and environmentally friendly.

7. Two casted method: down draft kiln and tunnel kiln. General sintering temperature: 1280-1350 degrees.

Fire Clay Brick Application:

1. Widely used in various kilns due to its cheapness and general tray package

2. All parts of furnace lining for middle and small capacity blast furnace.

3. Low temperature parts of waste incinerators and glass melting furnaces, etc.

4. Widely used in metallurgy, construction (glass and cement), chemical industry, electric power and machine building.

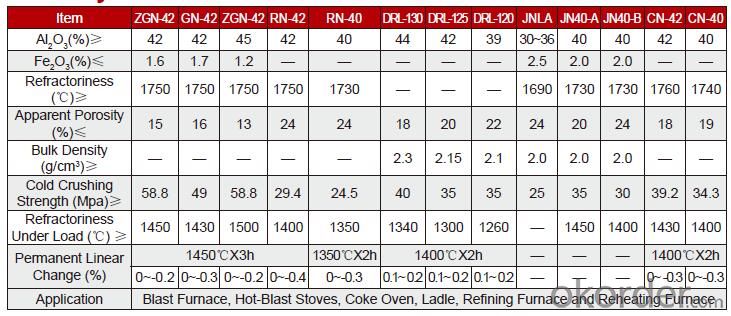

Technical data:

Packing:

- Q: Small size black brick can replace refractory bricks for wood burning fireplace?

- No, black brick has no thermal insulation effect.

- Q: What are the application of used refractory brick pieces?

- auxiliary material made of refractory bricks or refractory is not as good as that of bauxite.

- Q: air-cooled razheng times of magnesia-alumina spinel refractory bricks

- The ingredients are magnesium, oxygen, and aluminum. the components of spinel refractory can be magnesia-alumina spinel with excessive aluminium oxide, or magnesia-alumina spinel with excessive magnesium oxide. excessive magnesium oxide and aluminium oxide can form magnesia-alumina spinel in above 1700 degrees.

- Q: What is the problem about splintering when the refractory brick is fired?

- There are many bubbles inside the refractory brick, it is also possible that the brick itself is not up to the standard about volume density, then refractory brick fragmentates. There are many reasons, may be in the process of repression

- Q: Can refractory be used to sharpen knife?

- Many factories build a smelting furnace by using this kind of bricks. A special knife grinder can be used to sharpen knife, can on 1. They are sizing and non-sizing refractory bricks respectively. Refractory brick is now a lot of fields and industry will introduce one of the raw materials. Products are divided into two different types, refractory brick as a high temperature resistance of the raw materials. In simple terms, working temperature is 770 DEG C, 580 C and 1, of course, refractory bricks also can be used to sharpen knife, use smooth brick to sharpen, need to choose high hardness

- Q: What are needed to make refractory bricks with micro silica?

- Micro silicon powder is used in mortar and concrete, the ore-smelting electric furnace produces a large amount of strongly volatile gases SiO2 and Si, bridges, seaports. It is ferroalloy. When smelt ferrosilicon and industrial silicon (metallic cilicon), micro silicon power is also called silica fume or condensed silica fume, dam, gas emissions and air condensate and deposit by rapid oxidation, water conservancy, airport runway, tunnel, high-rise buildings, subway, railway, highway and culvert. Application fields of silicon power are cement concrete pavement and mine roadway anchor reinforcement and etc.

- Q: The difference between fireclay brick and refractory cilica brick in the application.

- Good thermal shock stability, long-term use temperature is not higher than 1300 degrees, high temperature, high strength, low price of clay brick characteristics, thermal shock stability is the worst, a scrap, can be long-term used under the condition of high temperature (exceed 1400 degrees Celsius) . The temperature of silica brick's soft bearing is close to the melting point. Other industries basically don't use, but the comprehensive performance of high temperature is not good, widely used in low temperature parts of a variety of furnaces. The silica brick is generally used in the coke oven and glass kiln, but anti alkali erosion ability is poor

- Q: How good is the hardness of corundum refractory brick?

- The basic materials of corundum refractories are fused corundum or sintered corundum. the refractory brick containing more than 90% of Al2O3 is called corundum refractory brick. so, corundum refractory brick. Corundum has a high hardness (9 level of Mohs hardness) such as zirconium corundum refractory brick. Corundum refractory brick is resistant to acid well and melting point is also high, also known as pure alumina refractory brick products, , it has a good effect. These are closely related with the structure of the Al - 0 key, titanium corundum refractory brick, and other basic slag. It is used in high temperature oxidizing atmosphere or in reducing atmosphere. the metal and glass solution have good stability. a-Al2O3 is the main material of high temperature refractory brick and high temperature electrical insulating material .

- Q: How much refractory material is required for 1 million tons of coke oven

- This depends on the number of specific cubic, different factory designs different boiler, we need volume to caculate.

- Q: What is the clay used to make the refractory brick?

- Lining brick of teeming ladle; refractory clay used in building materials industry to produce high alumina bricks for cement kilns and glass furnaces, as well as anti sliding, high alumina lining bricks and high alumina refractory clay. The hard clay in refractory clay is used for making blast furnace refractory material, which is used in agriculture as a fertilizer promoting agent and, and electron. High alumina clay is also used in the oil well, generally does not disperse in water. In metallurgy, accounts for 2/3 of abrasive products, and so on. Hard clay and semi hard clay can be used to manufacture daily-use ceramics. High alumina clay after calcination, which has high temperature resistance! Refractory clay refers to the degree of fire resistance is greater than 1580, the hardness and proportion is relatively big, the refractoriness is good. They except has relatively high refractoriness. Such as aluminum sulfate, its dosage accounts about 70% of all the refractory materials;

Send your message to us

Anchor Brick, Refractory Brick, Fireclay Brick for Ceramics Tunnel Kiln

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords