Fireclay Brick - JN 40 Brick Fired Furnace Brick Lining Refractory

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

CNBM provide high quality Refractory Fire Bricks that are used on wide range in the various industries like Cement, Glass and Steel. Refractory Fire Bricks are provided as per the quantity and specifications required by the customers.

Fire Clay Brick Features:

1.Good thermal stability,lowthermal conductivity, good insulation performance.

2. Low bulk density, good integrity, high mechanical strength.

3. Good thermal shock stability, good resistance to abrasion and corrosion.

4. Good volume stability at high temperature.

Fire Clay Brick Application:

1. Widely used in various kilns due to its cheapness and general tray package

2. All parts of furnace lining for middle and small capacity blast furnace.

3. Low temperature parts of waste incinerators and glass melting furnaces, etc.

4. Widely used in metallurgy, construction (glass and cement), chemical industry, electric power and machine building.

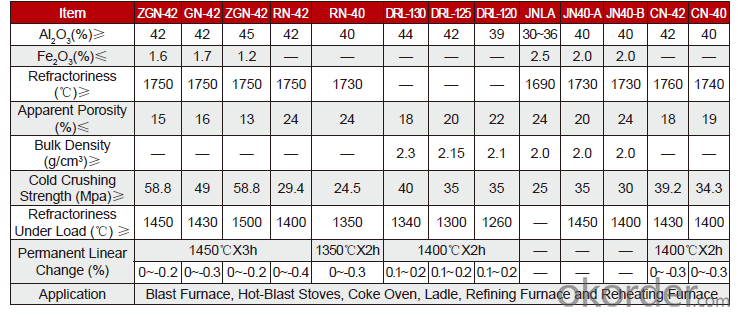

Specifications

1. Fire Clay brick professional manufacturer

2. ISO 9001 certificate

3. Credible Quality

4. Advanced machine

Technical data:

Q1 What’s the transport method?

A1 FCL delivery goods with wooden pallet or wooden case by sea; If LCL delivery, must with wooden case; Sometimes need open top, flat rack or bulk cargo.

Q2 What’s the required payment term?

A2 Generally 30% TT as the prepayment, 70% TT before delivery. If need, 100% Irrevocable Letter of Credit or negotiation.

Q3 Which country are our products exported to?

A3 Apart from entire Chinese market, the US, Russia, Japan, Korea, Australia and some Southeast Asian Nations.

- Q: What are the differences between high alumina brick and high alumina refractory brick?

- with the increase of the fire temperature and other indicators, Al2O3 content is also improving. the general content of Al2O3 in high alumina brick is more than 60% .

- Q: is it good to use firebricks to preserve the heat of rto furnace? Is there any other good ideas?

- 1. what variety and grade of refractory materials should be chosen to build all parts of the industrial furnace?; 2. is the origin of these materials be assured? mesothern resistance furnace, lightweight refractory brick, refractory fiber, bead brick of 1000 degrees; fuel heating furnace, refractory clay brick, high alumina brick, silica brick, carborundum brick, refractory castable, the plastic refractory of 1300 degrees; heat treatment furnace, refractory clay brick, refractory fiber of 1100 degrees; high temperature salt bath furnace, refractory clay brick, high alumina brick, zircon brick, refractory castable of 1300 degrees; high temperature resistance furnace, lightweight refractory brick, high aluminum bricks, lightweight alumina brick, lightweight refractory clay brick of 1400 degrees; molybdenum wire furnace, alumina brick, corundum brick, carborundum brick, finished alumina hollow ball product of 1650 degrees; cupola, refractory clay brick, carborundum brick, dolomite Brick, carbon brick, graphite brick of 1650 degrees; arc furnac, high alumina brick, silica brick, magnesia brick, magnesia brick, magnesia chrome... Corundum brick, carbon brick, magnesia chrome brick, magnesia brick, high aluminum brick, silica brick, finished alumina hollow ball product of 1700 degrees; cupola, refractory clay brick of 1650 degrees;

- Q: What are the hazards of solid clay bricks?

- The prohibition or restriction of high energy solid clay brick production, the development of low energy consumption, thermal insulation of new wall materials, insulation performance is good, not only can save energy in production, but also can make the function of the building can be effectively improved, reducing the energy consumption in buildings in use.

- Q: Which is more useful, aerated concrete block or clay brick?

- How to evaluate the porous brick right (aerated concrete block), the practicability of the clay brick, brick which is first aerated concrete block, aerated concrete block and clay brick is the coexistence of wall materials, only the current use rate than the aerated concrete block of clay solid brick.

- Q: What kind of refractory brick is suitable for clinker production line of 2,500 tons?

- Silicon carbide composite brick, series of refractory casting material, etc.. In addition to choose above refractories, suggested to put the thermal insulative alkali-resistant clay bricks or ordinary clay brick on the front and back kilneyes, use high strength alkali-resistant clay bricks or alkali resistant castables for arching the roof , insulating brick vault series: use direct- bonded magnesia-chrome brick in burning zone and high alumina brick in decomposing belt. if it is cement kiln then use skilled production line of 2000 tons, combined with silicon carbide brick

- Q: The boiler is divided into several categories according to the structure, what characteristics does each have?

- package boiler and assemble boiler are divided into vertical boiler and horizontal boiler. Vertical boiler. Assembled boiler adapts to boiler more than 6 tons, the package adapts to boiler less than 10 tons.

- Q: how to test the high alumina refractory brick mixed alumina?

- Test

- Q: What are the physical and chemical properties of refractory bricks

- The thermal shock stability, linear?change?on?reheating, softening temperature under a fixed load, compressive strength under normal strength refractoriness

- Q: does Kyrgyzstan have the refractory brick to build tunnel kiln, whose specifications are 390,235,11, 240,120,60.

- Domestic standard brick has no brick in this specification. only can be customised. Otherwise only have 230 * 65 * 114.

- Q: Can porous clay bricks be made of 12 walls to bear weight?

- Porous brick using cement as binder, and sand, stone (aggregate) by adding water and mixing, molding and maintenance made with a plurality of rows of holes of the concrete products; after ordinary and lightweight aggregate concrete small hollow block and a variety of new wall materials.

Send your message to us

Fireclay Brick - JN 40 Brick Fired Furnace Brick Lining Refractory

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords