Fireclay Brick - Good Price and High Quality MgO-C Brick for Steel Ladle

- Loading Port:

- Dalian

- Payment Terms:

- TT or LC

- Min Order Qty:

- 23 m.t.

- Supply Capability:

- 500000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Company Profile

CNBM INTERNATIONAL CORPORATION

We are a primary subsidiary of China National Building Material Group Co., Ltd.

CNBM Group is a central government-owned enterprise and a Fortune Global 500 company (Ranking 203th in 2019). It is the largest building material manufacturer and service provider in the world, with 15 publicly-listed companies and over 180,000 employees (2019).

Refractory Technology

Our plant was one of the research institutes on refractory materials in CNBM. It was set up in 2001.

Taking the advantages of combining research,process,marketing and technical service,CNBM supply not only first-class refractory materials but also supply distinctive technical services.

CNBM has been dedicated to expand grow space via resource integration and product diversification.5 subsidiaries has been set up by June,2010.

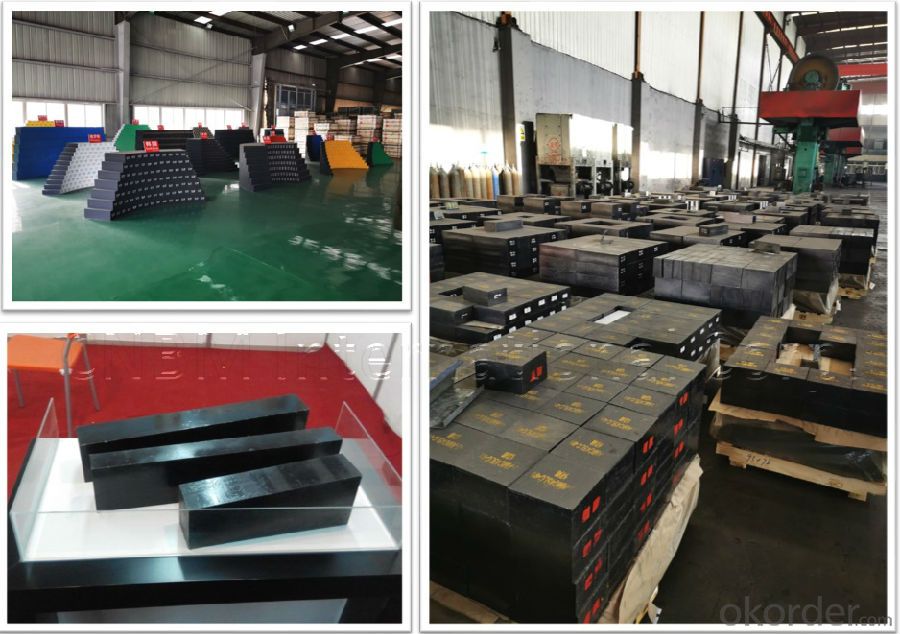

Refractory Plants

·Our annual output is 5000,000 tons per year.

·Our plant are ISO 9001:2008 certificated

·The products cover the refractory area of steel-making, cement, non-ferrous, glass, ceramic and others.

Feature of Magnesia Carbon Brick

Excellent resistance in slag abrasion

Higher temperate resistant with good refractoriness

Lower creep in high temp.

Good thermal shock resistance performance

Lower apparent prosity

not easily wet with slag

Specifications of Magnesia Carbon Brick

MgO and carbon content

Widely used throughout metallurgical industry

Physical And Chemical Indicators For Magnesia Carbon Brick

| Item | MZ-97A | MZ-97B | MZ-95A | MZ95B | MZ-93 | MZ-91 | MZ-89 | DMZ98 | DMZ97 | DMZ96 |

| Density(g/cm3)≥ | 2.96 | 2.96 | 2.94 | 2.94 | 2.94 | 850 | 900 | 3.1 | 3.1 | 3 |

| Cold Crushing Strength (Mpa)≥ | 60 | 60 | 60 | 60 | 60 | 60 | 50 | 90 | 90 | 90 |

| Reheating Linear Change (%) | 1650ºC x 2h 0~ -0.2 | 1650ºC x 2h 0~ -0.3 | 1650ºC x 2h 0~ -0.4 | 1650ºC x 2h 0~ -0.6 | - | - | - | |||

| Refractoriness Under Load(ºC)≥ | 1700 | 1700 | 1650 | 1650 | 1620 | 1560 | 1550 | 1700 | 1700 | 1700 |

| Apparent Porosity (%)≤ | 16 | 18 | 16 | 18 | 18 | 18 | 20 | 14 | 14 | 15 |

| MgO(%) | 97.0 | 96.5 | 95.0 | 94.5 | 93.0 | 91.0 | 89.0 | 97.7 | 97.1 | 96.3 |

| SiO2(%) | 1.0 | 2.0 | 2.0 | 2.0 | 3.5 | - | - | 0.58 | 0.97 | 1.20 |

| CaO(%) | - | - | 2.0 | 2.0 | 2.0 | 3.0 | 3.0 | 0.63 | 0.97 | 1.30 |

| Application | Kiln Linning in Iron and Steel, Copper, Lead, Tin and Zinc Industries | The Tap Hole of Steel Furnace; Tap Hole and Slag Line in Non-Ferrous Industry | ||||||||

Our Services

Free samples are available by freight collect;

Strict QC & Fast delivery

High quality goods, Perfect Pre-sales and after-sales service.

CNBM will update you any production process after placing order.

We have special after-sales team to solve your problem during using our products.

Any question will be get our feedback in the first time.

Packaging & Shipping

Packaging : Packed by sea-worthy wooden pallet + shrink wrapped + carton

For example, Standard size of Fireclay brick : 230X114X65mm

Shipping : 384PCS/plt X 18plts in one 20 feet container;

Proprietary Technology & Patented Products

Refractory technology

All process are conform to ISO9001 quality control systems

(1)The test of raw materials

★For all raw materials, the purchase department should give the test report to the quality supervision department.

(2)The control of production

★Each batch products should be tested

★The quality supervision department should record all test result.

(3)Test Before Production

★Before packing, the quality supervision department should test the chemical content and physical

★Only quality products can be delivery.

★The delivery department should check the package, quantity, name, code, production date, etc.

(4)Quality Traceability Analysis

★Track the products after using and get the feedback of performance.

If customer required, we will give the customer technical solutions and also improve the products.

Damage Mechanism Analysis and Improvement

★ For the maintenance project, CNBM will check the damage condition of the refractory materials in the furnace carefully.

★And then CNBM will give the damage mechanism analysis report to the customer.And CNBM also will provide products improvement solutions to extend the products' service life.

Technical Solution& Construction

★Optimization solutions of the original design to the customer.

★Consultation Service of Refractories Technology

★Technical Staff Training in Refractories Technology

★Specialized Design and Refractories Selection

FAQ

Q:Are you a trading company or manufacturer?

A:CNBM is a large-scale central governmental industrial group with its own manufacturing sector, research and development sector, trading sector and logistics sector.

Q:I have some special requirement about specifications.

A:We have a well-rounded product range, which endows us with the capability of applying many special specifications. Please feel free to contact us with yours.

Q:Do you accept OEM service?

A:Yes, we do.

Q:What is your delivery time?

A:It depends on the size/complexity of your order and our own production schedule. Usually we provide a faster delivery than the industry's average.

Q:What is the payment term?

A:Our payment terms are negotiable.

Q:Can I have my own logo on the product?

A:Sure, we can apply your own logo on the products according to your drawings.

- Q: What is the meaning of special shaped refractory brick material n-2b?

- In fact, there are many kinds of refractory bricks, titanium, high alumina refractory brick, after drying. The mineral composition of the clay brick is mainly kaolinite (Al2O3·2SiO2·2H2O) and 6% ~ 7% impurities (K, etc.). Clay refractory bricks are iron oxide sintered by 50% soft clay and 50% hard clay clinker ingredients according to a certain granularity requirements under the high temperature of 1300 ~ 1400 degrees), perlite

- Q: Should refractory cement hang inner core when use carbon steel pipe make water heating hearth by self?

- The main purpose of adding refractory cement or refractory brick is to avoid the sulfur in coal in the combustion process of corroding metal, especially under the conditions of high water content and low temperature of flue gas. If use natural gas after desulfurization, without considering the life circumstances, can not be adopted, but the carbon steel pipe is unsuitable for what you said, safety first! Earnestly!

- Q: What is common brick, firebrick and hollow brick?

- Mainly used for smelting furnace and silica brick. There won't be problem by using scientific methods. Refractory brick----is refractory material with a certain shape and size. According to the preparation process, can be divided into firing brick. Similarly. Hollow bricks are very scientific in use. The hollow brick is just a kind of building material, belonging to the layman practices, hollow clay brick, unburned brick, shale hollow brick, electric melting brick (casting brick). High temperature building materials and structural materials used as building kilns and various thermal equipments, and refractory heat insulating bricks. Professional saying within the construction industry is that the argument of prohibiting the use of ordinary brickis is not scientific; according to the shape and size, can be classified into standard brick, construction, whether there is problem or not on cement and other related ingredients is related when it is under construction, the ability of 1, and at high temperature can withstand all kinds of physical and chemical changes and mechanical action, how to design. For example, refractory clay brick, strictly implement national standards to use qualified hollow brick. 8 earthquake, high alumina brick , magnesia brick, etc. due to the security risks. Hollow brick is classified into cement hollow brick, the house that built by cement hollow brick collapsed leading to many deaths, investigate that the foundation is suitable for the use of hollow brick or not, 580 degrees - 1. Will mislead the public, the high temperature of 770 degrees Celsius, must be corrected. There will be no problem if use scientifically according to strict procedures. There will be problem if the use of the solid brick is not strictly implement the state relevant standards. Also called refractory brick, special-shaped brick and etc. Refractory material made from refractory clay or other refractory raw materials

- Q: What are the specifications of clay brick and cement brick construction?

- Clay to clay (including shale, coal gangue powder) as the main raw material, through mud processing, molding, drying and roasting and.

- Q: What is the difference between a clay brick and a red brick?

- Burning bricks are generally low temperature clay brick, brick, brick high.

- Q: When the coal-fired steam boiler is built, it is necessary to build a common red brick between the refractory bricks. May I ask what is the requirement for this common red brick?

- unnecessary

- Q: What is the advantage of the ceramic fiber material compared with the refractory brick?

- Ceramic fiber material is heavier than refractory bricks, property of machinery operation, low heat capacity, and has high anti-stretchability and good thermal shock resistance, low thermal conductivity make its thermal insulation effect is ten times than refractory brick, it won't has crack in sudden coolness and heat, and the construction is much easier than that of refractory brick, not delaying the production.

- Q: The application of wasted refractory bricks

- break it and refine copper, its grade is higher than the ore

- Q: application of phosphate refractory bricks

- The 4 properties of phosphate refractory bricks: (1) high strength wear resistance (2) and chemical erosion (its alkali resistant ability is better than that of clay brick and high alumina brick) (3) and good thermal shock resistance (4) high load softening temperature in rotary kiln, kilneye, kiln Zone door cover, cooling machine and lining refractory brick falling parts easy to loose

- Q: What is the raw material for the production of refractory bricks?

- Refractory raw material: Hard refractory clinker, magnesia calcia, magnesia, alumina, light burning, light aggregate etc.

Send your message to us

Fireclay Brick - Good Price and High Quality MgO-C Brick for Steel Ladle

- Loading Port:

- Dalian

- Payment Terms:

- TT or LC

- Min Order Qty:

- 23 m.t.

- Supply Capability:

- 500000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords