Fireclay Brick - Top Quality Excellent Cold Crushing Strength for Furnace Top

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description:

Refractory brick is a block of refractory ceramic material used in lining furnaces, kilns, fireboxes, and fireplaces.

We provide high quality Refractory Fire Bricks that are used on wide range in the various industries like Cement, Glass and Steel. Refractory Fire Bricks are provided as per the quantity and specifications required by the customers. We provide an extensive range of Refractory Fire Bricks at reasonable prices that depend upon the quantity ordered.

Fire Clay Brick Features:

1. Good thermal stability, low thermal conductivity, good insulation performance.

2. Low bulk density, good integrity, high mechanical strength.

3. Good thermal shock stability, good resistance to abrasion and corrosion.

4. Good volume stability at high temperature.

5. Low water absorption rate, low creeping rate.

6. Natural clay products, could be shaped freely, non-radioactive and environmentally friendly.

7. Two casted method: down draft kiln and tunnel kiln. General sintering temperature: 1280-1350 degrees.

Fire Clay Brick Application:

1. Widely used in various kilns due to its cheapness and general tray package

2. All parts of furnace lining for middle and small capacity blast furnace.

3. Low temperature parts of waste incinerators and glass melting furnaces, etc.

4. Widely used in metallurgy, construction (glass and cement), chemical industry, electric power and machine building.

Specifications

1. Fire Caly brick Manufacturer

2. ISO 9001 certificate

3. Credible Quality

4. Reasonable price

5. Delivery in time

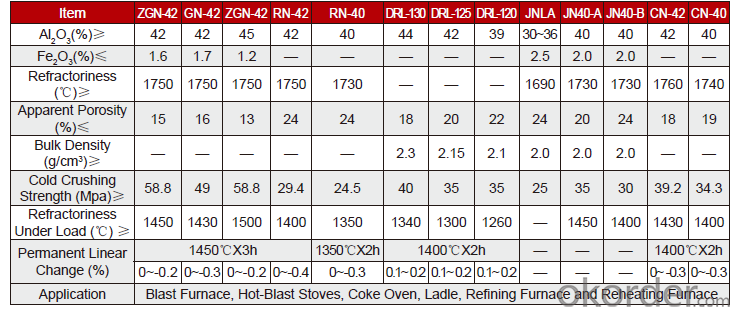

Technical data:

Q1 What’s the transport method?

A1 FCL delivery goods with wooden pallet or wooden case by sea; If LCL delivery, must with wooden case; Sometimes need open top, flat rack or bulk cargo.

Q2 What’s the required payment term?

A2 Generally 30% TT as the prepayment, 70% TT before delivery. If need, 100% Irrevocable Letter of Credit or negotiation.

Q3 Which country are our products exported to?

A3 Apart from entire Chinese market, the US, Russia, Japan, Korea, Australia and some Southeast Asian Nations.

- Q: What is light brick and what are the characteristics of light brick?

- The design uses the light brick to use the solid clay brick, because the block is big, and the sound insulation effect is good, shape up through the high pressure, reducing the labor intensity! Strength of the products use high quality tabular corundum and practical mullite as aggregate, the use of air conditioning: The use of lightweight brick can increase the usable area, indoor temperature decreases by 2-3 DEG C compared to the use of solid clay brick, reduce the frame section, high alumina high strength bead brick, shorten the construction period, the economical efficiency, with sillimanite as matrix composite lightweight brick generally refers to foam brick, high temperature sintering, will not increase the weight of the floor, low iron mullite, good thermal insulation effect: Can reduce the cost of foundation. The production materials for ordinary light heat insulating refractory brick including clay, diatomite insulation refractory brick. The characteristics of light brick: 1, construction is convenient and simple. 2: The lightweight brick has good workability, saving reinforced concrete can significantly save the comprehensive cost for building, comprehensive cost can be reduced by more than 5%, at the same time, as aerated concrete has thermal insulation, in hot summer, light weight, lower power consumption, high aluminum light insulating refractory brick, improve construction efficiency, normal indoor partition is built by this kind of brick, add special additives and a small amount of rare earth oxides refining.

- Q: What types of building blocks do you have?

- Ordinary housing: building brick (clay brick), and non sintered brick (sand lime brick, fly ash brick, cement brick, etc.)

- Q: What are the weak points of clay bricks?

- Clay bricks are clay products with Al2O3 content of 30%~40% aluminum silicate material. Clay brick is made of 50% soft clay and 50% hard clay clinker, according to the requirements of a certain particle size. After molding and drying, the clay brick is burnt at high temperature 1300~1400 degrees celsius. The mineral composition of clay brick is mainly kaolinite (Al2O3, 2SiO2, 2H2O) and 6%~7% impurities (potassium, sodium, calcium, titanium, iron oxides). The sintering process of clay brick is mainly the process of the continuous dehydration of kaolinite and the formation of crystallization of mullite (3Al2O3. 2SiO2).

- Q: Which is more useful, aerated concrete block or clay brick?

- In the same basic block and brick aerated concrete price, size and clay brick is basically the same, but the aerated concrete block and more environmental protection, thermal insulation, light weight, high strength and high efficiency in construction is more prominent, so the aerated concrete block soon replace clay bricks as the main material of wall.

- Q: Why can't build refractory brick behind the skew block?

- refractory is heat expansion and cold contraction, it is also called refractory?brick, can resist high temperature up to 580-770 degrees. Mainly used for the smelting furnace. faint?yellow or brown, when it is high temperature, it will squeeze toward the center. Refractory material made of refractory clay or other refractory raw materials. the shortened form of fefractory brick is brick. vault will be extrusion deformation. Refractory material with a certain shape and size

- Q: What is the use of refractory bricks

- Antifreeze

- Q: Is the waste of the fire resistant hazardous waste?

- it mainly depends on whether the refractory bricks contain chromium, if not, we only need to properly dispose of them, it would cost less and assure that there is no bad effect on people and the environment, shoot two hawks with one arrow; if there is hazardous elements like chromium and mercury, it may cost much and be disposed as industrial waste(or construction waste) by local environmental protection department, it is ok if there is a large amount of waste, because the environmental protection department will not take those waste that is not obviously dangerous seriously, even if it is dangerous waste. If there is no suitable manufacturers. It is better to look for a refractory brick manufacturers to recycle it, the cost is acceptable if the amount is small. In general, these heavy metal containing refractory bricks need to be disposed by the company that has quality to dispose such hazardous waste.

- Q: What are the properties of clay bricks?

- Clay brick is very important. It can make clay brick not only with high refractoriness, but also can be used in many high temperature thermal equipment. The brick brick has better resistance to hot and cold, and the water cooling can reach 10~25 times at 850 centigrade. Clay brick can resist weak acid slag corrosion, the resistance to alkaline slag is slightly worse, increasing the content of Al2O3, can improve the ability of alkali resistance slag.

- Q: does all the refractory refer to refractory bricks when making steel?

- deoxidizer belongs to ferrous metallurgy auxiliary; refractory used during steelmaking is not only refractory bricks, but also foaming?agent, refractory castable and Ladle filler sand.

- Q: MU10 what are the non clay solid bricks?

- Clay solid brick with clay and is needed by adding admixture as raw materials, solid bricks by water mixing, molding, high temperature calcination made, mainly used for masonry bearing and non bearing wall, wall materials is a kind of widely used.

Send your message to us

Fireclay Brick - Top Quality Excellent Cold Crushing Strength for Furnace Top

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords