Fireclay Brick - Fire Resistant Refractory Low Porosity for Glass Furnace Regenerator

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 100 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description:

High alumina fireclay Brick for Heating Furnace is a kind of insulation material adopting organic matter as ignition loss substance in order to increase the porosity of refractory, which has such advantages as high porosity, small volume density, good insulation effect, high mechanical intensity, small thermal conductivity and long service life. For various industrial kilns & furnaces, it is a kind of essential refractory for energy saving and temperature preservation.

This series of High Alumina fireclay Brick for Heating Furnace are made of selected high alumina bauxite, kaolin clay, hollow microsphere as the mian material.By shaping at high pressure and sintering at high temperature

Product Applications:

1. Furances of glass,coke oven,electric and so on

2.Furnaces of metallurgy industry, heat treatment furnace

3. Furnaces of chemical industry and construction industry.

4. Furnace of incineration of garbage, recirculating fluidized bed furnace

5. Standard sizing: 230 x 114 x 65 or 75 or 25 mm others up to the client

Main Product Features:

1. Low porosity,High bulk density.

2. High Cold Crushing strength.

3. High refractoriness under load.

4. High mechanical strength.

5. Good resistance to erosion.

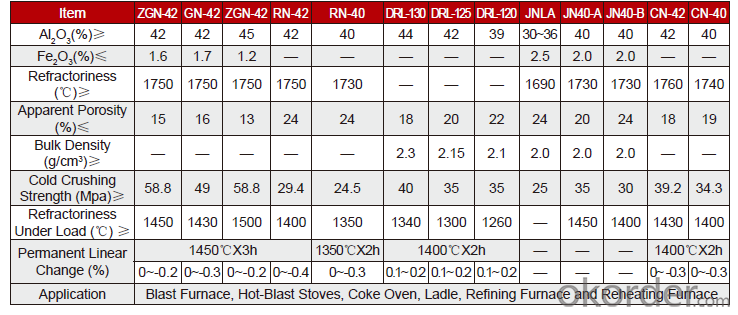

Product Specifications:

1.With 55% Al2O3 min;

2. Refractoriness: 1750C min;

3.For steelmaking furnaces;

4.ISO 9001 Certificate;

5.Custom shape;

Technical data:

FAQs:

Q1 What’s the transport method?

A1 FCL delivery goods with wooden pallet or wooden case by sea; If LCL delivery, must with wooden case; Sometimes need open top, flat rack or bulk cargo.

Q2 What’s the required payment term?

A2 Generally 30% TT as the prepayment, 70% TT before delivery. If need, 100% Irrevocable Letter of Credit or negotiation.

Q3 Which country are our products exported to?

A3 Apart from entire Chinese market, the US, Russia, Japan, Korea, Australia and some Southeast Asian Nations.

- Q: Whether the cement kiln refractory bricks belong to hazardous waste or not?

- Refractory brick produce dust hazards if it is broken, It is also should be paid attention to that if is refractory brick containing chromium, which will easily produce Cr VI when met with water, Cr^6+ material produced by magnesia chrome bricks is difficult to be damaged in the environment, which in many cases will exist in nature for a long time, continue to endanger human health. Chromite, as the raw materials to make magnesia-chrome brick, often exists in the form of trivalence (Cr203), is not toxic, nor carcinogenic, but in the cement rotary kiln high temperature oxidation atmosphere, it reacts with alkali metal oxide in cement materials, will produce chromic acid and alkali acid which is harmful to people's health. There are MgOIn contained in broken magnesia-chrome bricks, whose water solution is weakly alkalinity and generally will not easily produce K2cr207. K2Cr04 is a kind of weak oxidaiblity chemical compound, which has high chemical stability. It is very difficult to be reverted to non-toxic trivalent chromium when it blends into the environment. In many cases, these chemical compounds containing Cr VIcompounds will exist in nature stably, causing long-term pollution to the environment. This kind of harm is sustainable. The second reason that is very serious is that the high grade chrome ore is less and less in the world, forcing refractory manufacturers to find and develop

- Q: What is the role of refractory brick, whether is there any books to introduce refractory bricks

- Fire resistant, flame retardant, used for building stove and firewall,

- Q: The brick and ordinary clay brick which is expensive

- The difference is mainly the material, as for the production, the two are fired high temperature

- Q: Can common cement mortar be used to build the lining of chimney refractory brick?

- No. You have used fire bricks, which shows there is a certain temperature inside, you'd better use refractory cement

- Q: Is the waste of the fire resistant hazardous waste?

- Can be recycled and reused.

- Q: T38 size of high alumina refractory brick

- 230*114*65/55

- Q: What's the difference between fired clay bricks and sintered porous bricks?

- Fired clay brick is a common brick made of clay as the main raw material. It is divided into five strength grades MU30, MU25, MU20, MU15 and MU10 according to the compressive strength. Strength, resistance to weathering of radioactive material and qualified brick, according to the size deviation, appearance quality, efflorescence and lime burst divided into high-class product (A), Al (B), (C) three qualified product quality grade. Excellent products for drywall and wall decoration, wall can be used for mixing first-class products, qualified products. Medium frosted bricks should not be used for damp parts. The shape of the brick is right angled hexahedron, its nominal size is: 240MM long, 115MM wide and 53MM high. The product mark of brick is written according to the product name, category, intensity grade, quality grade and standard number.

- Q: What are the differences between fired brick and clay brick?

- . Sintered brick is mainly different from cement bricks and so on, not burning bricks at high temperature. Clay fired brick is widely used in paving roads, pavements and clean walls.

- Q: What kind of refractory material is used in the furnace when the boiler reaches more than 1200 degrees?

- except refractory brick, refractories include refractory concrete (refractory cement+aggregate), fire-resistant insulating layer (refractory cement+vermiculite powder or refractory cement + diatomaceous earth) and so on.

- Q: What material is good of refractory bricks?

- It can also be divided into a variety of kinds, it mainly depends on where it is used, each has its own advantages, neutral three categories of refractory bricks have a variety of materials

Send your message to us

Fireclay Brick - Fire Resistant Refractory Low Porosity for Glass Furnace Regenerator

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 100 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords