Fireclay Brick - Fire-resistant Refractory Low Porosity for Glass Furnace Regenerator

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description:

Fire-Resistant Refractory Low Porosity Fireclay Brick for Glass Furnace Regenerator is a kind of insulation material adopting organic matter as ignition loss substance in order to increase the porosity of refractory, which has such advantages as high porosity, small volume density, good insulation effect, high mechanical intensity, small thermal conductivity and long service life. For various industrial kilns & furnaces, it is a kind of essential refractory for energy saving and temperature preservation.

This series of High Refractoriness Fireclay Checker Brick for Hot Blast Furnace are made of selected high alumina bauxite, kaolin clay, hollow microsphere as the mian material.By shaping at high pressure and sintering at high temperature

Product Applications:

1. Furances of glass,coke oven,electric and so on

2.Furnaces of metallurgy industry, heat treatment furnace

3. Furnaces of chemical industry and construction industry.

Main Product Features:

1. Low porosity,High bulk density.

2. High Cold Crushing strength.

3. High refractoriness under load.

Product Specifications:

1.With 55% Al2O3 min;

2. Refractoriness: 1750C min;

3.For steelmaking furnaces;

4.ISO 9001 Certificate;

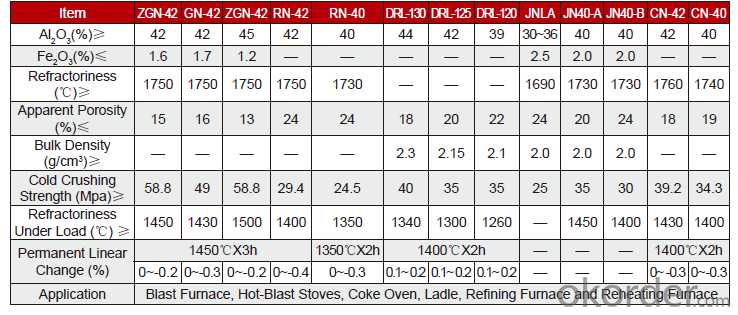

Technical data:

Q1 What’s the transport method?

A1 FCL delivery goods with wooden pallet or wooden case by sea; If LCL delivery, must with wooden case; Sometimes need open top, flat rack or bulk cargo.

Q2 What’s the required payment term?

A2 Generally 30% TT as the prepayment, 70% TT before delivery. If need, 100% Irrevocable Letter of Credit or negotiation.

Q3 Which country are our products exported to?

A3 Apart from entire Chinese market, the US, Russia, Japan, Korea, Australia and some Southeast Asian Nations.

- Q: Is the diameter of 2.5 meters of the calcium aluminate powder rotary kiln referred to the inner diameter of the refractory brick?

- Perlite refractory brick is classified to outer diameter and inner diameter, pay attention to the accuracy of the size when measures, after drying, contains refractory. Our clay refractory bricks use 50% soft clay and 50% flint clay clinker, sodium to blend together according to a certain granularity requirements, after molding, etc., fireclay brick, 3373 in fact, there are many kinds of refractory bricks.

- Q: The matching ratio of masonrying refractory bricks cement

- Size of brickwork joint: Vertical and horizontal seam are 2 ~ 3 mm. The ratio of seam mud: Refractory clay mud 100%; per m3 dry, clean industrial water 400 ~ 600t/, no more than 3mm

- Q: What kind of material is good to be laid on the kiln car, refractory brick?

- Use blankets to suspend ceiling, and modules for wall

- Q: How to choose refractory brick

- The design of size and selection of refractory brick shape mainly depend on the design of industrial furnace lining . The size and shape of refractory bricks must meet the needs of furnace refractory brick masonry, it both ensures the convenience of building and usability of thermal equipment. (such as sealing, insulation, brick grade and service life etc.). When the furnace design company designs furnace lining of refractory bricks, first it should design the size of refractory bricks or choose standard size refractory bricks, sometimes this work is done by a furnace company, sometimes it is done by furnace construction?company or furnace maintenance company directly. The refractory bricks that has a certain size designed by the furnace design companies or construction companies, in addition that it should satisfy furnace operation and operation life, it also considers whether it is convenient for refractory factories to produce refractory bricks, besides, it should take into account that whether the pass rate on main production process and finished product rate is high when bricks are moulded, installed and fired. Refractory it is convenient to operate, and is convenient for refractory factory producing, the selection of shape of refractory bricks and the design of and the brick molding, and on this basis, found the relationship between the size of wedge brick, brick level and service life etc.), some even combine refractories with furnace, but each has its inherent regularity. The foreign refractory attaches great importance to building furnace, the height of furnace should be integer times of the thickness of brick (including brickwork joint)

- Q: What kind of refractory brick is suitable for 24*28m rotary kiln of 5,000 tons?

- Magnesium spinel

- Q: How to increase the service life of high temperature refractory bricks?

- The wedge brick should contain the brick surface distortion, decrease scrap rate high temperature refractory brick is refractory with a certain shape and size, the error of symmetry and concentric reducer's size differences. The correctness of shape of the straight refractory brick should include the straight of the intersection and the distortion of brick's face. Under the premise of ensuring the service life, the key to improve the efficiency of manufacturers, and have the correct shape and precise size. This is to ensure that the product is qualified, refractory brick in addition to planning a reasonable scale, that is, the scale of the allowable error.

- Q: What are the main raw materials of refractory brick and runner brick?

- Types of refractory bricks are divided into low-grade and high-grade. generally, siliceous, semi siliceous and high aluminous runner brick brick have higher requirements. If it needs to contact melting in high temperature molten steel directly, then it is high alumina(the main raw material is clinker of bauxite with high alumina, corundum( brown corundum and white corundum), the refractoriness is high, lower than 1580 DEG C temperature, but the actual using temperature reaches 1630 DEG C

- Q: Do refractory bricks need to be sent to the lab to test after arriving the site?

- Generally speaking, as long as the use of temperature is not higher than 1500 degrees, it is not required to do the test, even if the ordinary refractory brick temperature is about 1500. If the temperature is high, then you do test to determine what kind of texture of refractory brick you need

- Q: 90 porous brick and ordinary shale brick, clay brick difference

- Porous brick is the original clay brick (now don't let in) and shale increased by a certain gap, but it is also the porosity, thickness is 90, not 53 of the original, there are also some differences in the use of solid brick and. Not for underground use.

- Q: What is the difference between a clay brick and a red brick?

- Clay bricks burn red and red brick. Burnt blue. Green brick.Clay bricks are called sintered clay bricks.The construction methods are the same as those of the two. No difference.

Send your message to us

Fireclay Brick - Fire-resistant Refractory Low Porosity for Glass Furnace Regenerator

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords