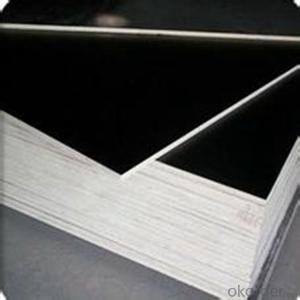

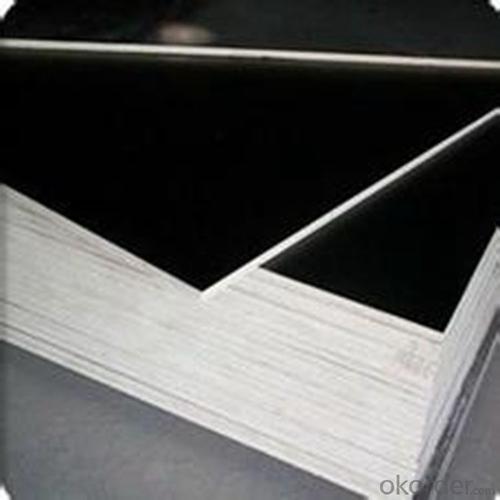

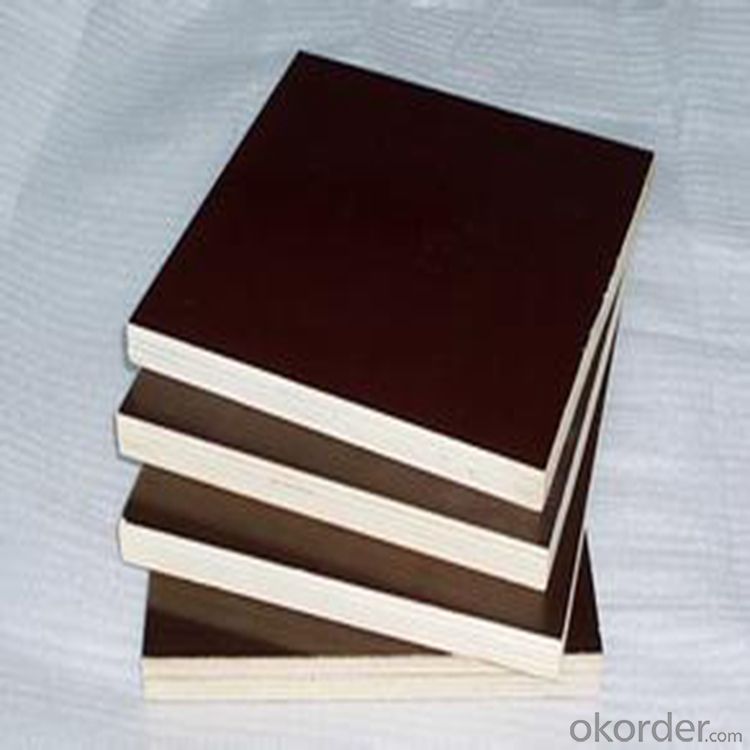

Exterior Grade Film Faced Plywood with Good Quality

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m³

- Supply Capability:

- 10000 m³/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Description

General Information

Plywood is a wood product manufactured out of many sheets of veneer, or plies, pressed together and glued, with their grains going in opposite directions. Most plywood is made from an odd number of layers, called plies (typically 3, 5 or 7), with an equal number of plies on each side of the center ply.

Feature

1.No need of release agent, easy to demoulding.

2.Light in weight, easy to use, can be cutted to any size.

3.Firmly surface, perfect concrete molding.

4.The core will never crack and deformed. Can be used more than 10 times

Specifications

1.ISO9001:2008;CE.

2.Face/Back:Okoume,Bintangor,Kuruing,Teak

3.E0,E1,E2,MR glue

4.Size:1220*2440/1250*2500mm

Advantages

1. Above 18mm thickness , could be used 20 time at least

2. The inside each veneer is whole core

3. Each veneer is glued totally

4. Boiled for 10 hours , will not cracking

5. Twice hot press to strong joining capacity

6. Cold press again to strong joining capacity

7. 100% Dry

8. We have another glue making factory

Data sheet

| Product Name: | FILM FACED PLYWOOD |

Place of origin: | China | |

Minimum order: | 1x40’HC | |

Terms of payment: | L/C at sight, T/T | |

Delivery lead time: | 30 days after L/C | |

Supply ability: | 3,000CBM/month | |

FILM FACED PLYWOOD | ||

Specifications: | ||

1) Faces: BROWN/BLACK FILM | ||

2) Grades: A/A | ||

3) Cores: Poplar, Birch, Hardwood ,MLH (mixed light hardwood) | ||

4) Glue: MR, WBP, Melamine | ||

5) Dimensions: 1220mm x 2440mm, 1250m x 2500mm | ||

6) Size: 12mm-25mm | ||

7) Usage: For construction | ||

Packing: Seaworthy packing | ||

Mechanics Performance | ||

1) Moisture content≤10% | ||

2) Density: Above 0.75/cm3 | ||

3)Wearing and tear value≤0.1g/100r | ||

4)Wash the intensity of defying: 40kj/m2 | ||

5)Elastic mould amount≥5000MPa≥7948MPa | ||

6)Intensity of the quiet song≥24MPa≥75.8MPa | ||

7)Warping degree≤1% | ||

8)Thickness tolerance: ±0.5mm | ||

9)Thickness expanding rate≤8% | ||

Packaging & Shipping

Packaging Details: Inner packing: 0.2mm thick plastic bag

Outer packing: pallets covered with plywood/carton, then steel taped for strength

Delivery Detail: Within 20 days after receiving deposit or Original L/C at sight

Our Services

1 . Customized request plywood production

2 . OEM and ODM service

3 . Customized logo printing

4 . After-sale service

5 . Booking shipping schedule

Company Information

CNBM (China National Building Material) Group is the largest comprehensive building materials group in China that in integrate scientific research, manufacturing and logistics into one entity. The largest building materials and equipment specialists in China. Upon State Council approval, today CNBM owned more than 300 subordinate manufacturing factories and servicing companies. There are 6 fully owned public listed companies and 11 partially owned with substantial shares public listed companies. In many of these fields, CNBM is playing the leading role in the building industry in the country.

FAQ

• Can the size of your product change?

The common size is 1220 x 2440 x 2.5mm, but as your requirement, we can change the size of our product but it will have a minimum order

• How can I get some samples? Free or not?

We can send some normal samples, absolutely free.

• How does your factory do regarding quality control?

"Quality is priority." We always attach great importance to quality controlling from the very beginning to the very end. Our factory has gained ISO9001 , SGS authentication, CE for Europe, etc.

- Q: The difference between the multilayer board and the plywood is as follows

- Commonly used plywood, plywood and other multi-layer board. Multilayer boards can improve wood utilization and are a major way to save wood

- Q: Now what is the market for plywood development?

- From January to November 2007, China's plywood manufacturing industry achieved a total industrial output value of 101,828,484 thousand yuan, an increase of 48.27% over the same period last yea

- Q: What is the composition of the plywood?

- Usually with odd-numbered veneer, and the adjacent layer of the fiber in the direction perpendicular to each other. 【Content compiled from Sina decoration grab the foreman】

- Q: What is the best way to fix multi-layer plywood?

- The usual length and width specifications are: 1220 × 2440mm, while the thickness specifications are generally: 3,5,9,12,15,18 mm and so on

- Q: Furniture solid wood and plywood which is better? Such as bed `wardrobe` TV cabinet `table

- the difference between the process: multi-layer solid wood flooring will be a layer of each layer of scientific criss-cross, to eliminate internal stress, at present, its layers have grown from 7 to 9 layers, 11 layers

- Q: Multilayer plywood with what method is fixed

- usually with odd-level veneer, and the adjacent layer of veneer Of the fibers are perpendicular to each other

- Q: Ordinary plywood is divided into four categories

- According to different density, divided into 80, 70, 60 three categories. Quality level for the premium, one, two three

- Q: What are the advantages and disadvantages of plywood?

- Plywood is cut from the wood section into a veneer or cut from the wooden square cut into thin wood

- Q: Decorative veneer veneer plywood features

- Decorative veneer is made of high quality wood by slicing or peeling processing made of thin wood chips.

- Q: What is the plywood made of wood?

- usually with odd-level veneer, and the adjacent layer of veneer Of the fibers are perpendicular to each other.

Send your message to us

Exterior Grade Film Faced Plywood with Good Quality

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m³

- Supply Capability:

- 10000 m³/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords