Plywood 1/4 Film Faced Plywood Shuttering Plywood WBP Glue Poplar Core

- Loading Port:

- Lianyungang

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m³

- Supply Capability:

- 20000 m³/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Specification:

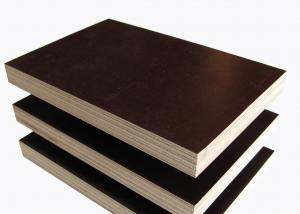

Item name:Black/Brown Film Faced Plywood

Size:1220*2440/1250*2500

Core: poplar/hardwood/combi/birch

Glue: WBP, melamine, phenolic

Description:

Product Name | Film faced shuttering plywood |

F/B | Black film, brown film,red film |

Grade | Construntion grade(one/two time hot press) |

Core | Poplar, hardwood, birch, pine, combi , and so on |

Glue | mealmine and WBP |

Thickness | 9-25mm |

Specification | 1220x2440mm, 1250x2500mm,915x1830mm |

Moisture Content | 8-10% |

Package | Standard export packing |

Press | one times press/two time press grade |

MOQ | 1x20GP |

Price Terms | FOB, CIF, CFR |

Payment | T/T 30%, irrevocable LC |

Delivery Time | Within 15 days after order confirmed |

Supply Capacity | 4500 cbc/month |

Usages | Can be widely used for building concrete, etc |

Remarks | Top class equipment with top class produce technique; Credit first, fair trading |

Formaldehyde Emission Standards | E2<30mg/100kg E1<9mg/100kg E0<5mg/100kg Phenolic film faced plywood |

Features:

1. The face should be of high resistance to corrosion and moisture.

2. The face should be smooth and easy to take off from cement and easy to clean.

3. The core should be water resistant and won’t swell.

4. The core should be strong enough and won’t break.

5. The edge should be sealed and water proof.

Advantages of our film faced plywood

1. Above 18mm thickness film faced plywood , could be used 20 time at least

2. The inside each veneer is whole core

3. Each veneer is glued totally

4. Boiled for 10 hours , will not cracking

5. Twice hot press to strong joining capacity

6. Cold press again to strong joining capacity

7. 100% Dry

8. We have another glue making factory

FAQ

A. Quality :

With the skilled worker ,mature technology and ten years experience ,all our plywood are steady quality .

B. Price:

Due to the skilled worker ,mature technology and an experienced operating system , we can

quote you competitive price , so that you will have the price advantage to capture your market.

C.Service:

7*24hours , if any need, you can email or call us,we will do our best to meet your demand

D.Export experience:

Over ten years experience for exporting ,We are much familiar with

the export operation .

- Q: What are the further processing of plywood?

- Direct printing plywood Direct print plywood is printed directly on the plywood surface with simulated wood grain or other patterns.

- Q: Judging wood is the standard for plywood

- If you can identify the type of wood used by your own furniture, it will help you identify the true value of the furniture

- Q: How to use building plywood?

- in the decoration works mainly used in ceilings, wall skirts, floor linings and so on.

- Q: According to the different composition of the glue, for the construction of plywood with the following types of glue

- According to the environmental protection level, the glue used for plywood can be divided into E0 grade, E1 glue, E2 glue (and even E2 level are not reach the unqualified glue)

- Q: Furniture solid wood and plywood which is better? Such as bed `wardrobe` TV cabinet `table

- and the general splint or plywood Need, the number of layers is relatively less, in the balance of internal stress

- Q: Further processing of the plywood

- plywood treated plywood plywood used in the manufacturing process or after manufacturing to deal with the physical properties of coupons.

- Q: What is the density of plywood?

- Plywood can improve timber utilization and is a major way to save wood

- Q: One of the commonly used materials for furniture is a wood-based panel

- The number of layers is generally odd, and few are even. Vertical and horizontal direction of the physical and mechanical properties of small differences

- Q: Does plywood contain formaldehyde?

- All plywood products will produce a small amount of formaldehyde. New products discharged from the most formaldehyde, the longer the use, the taste less, but are to be completely volatile for many years.

- Q: The usual length and width specifications are:

- Solid wood refers to pure solid wood, that is, all materials are not re-processed natural materials, do not use any furniture made of wood furniture.

Send your message to us

Plywood 1/4 Film Faced Plywood Shuttering Plywood WBP Glue Poplar Core

- Loading Port:

- Lianyungang

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m³

- Supply Capability:

- 20000 m³/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords