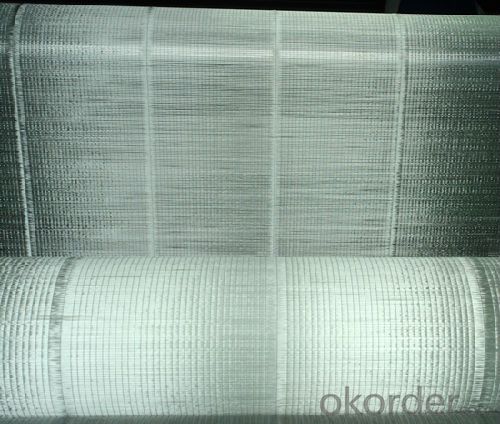

Fiberglass Mat Tissue Stitched Mat Triaxial for FRP Application

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 kg

- Supply Capability:

- 100000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Brief Introductions

E-glass stitched combo mat consists of two or more layers of fiberglass roving which are stitch-bonded.One layer of rovings and different layers of roving can be oriented differently and have different liner density.The roving specification,number of roving layers,mat width and roll diameter can be customized as per requirement.

Multi-axial series: At most 4 layers of roving can be stitched;however a layer of chopped strands(0g/㎡-500g/㎡)or composite materials can be added.The maximal width can be too inched.This product is used in blades of wind power turbines,boat manufacturing and sports devices.

Product Features

Product Specifications

Product no. | Overall Density | 0°Roving Density | .+45°Roving Density | .-45°Roving Density | Chop Density | Polyester Yarn Density |

(g/m2) | (g/m2) | (g/m2) | (g/m2) | (g/m2) | (g/m2) | |

E-TLX600 | 614.9 | 3.6 | 300.65 | 300.65 | - | 10 |

E-TLX750 | 742.67 | 236.22 | 250.55 | 250.55 | - | 5.35 |

E-TLX1180 | 1172.42 | 661.42 | 250.5 | 250.5 | - | 10 |

E-TLX1850 | 1856.86 | 944.88 | 450.99 | 450.99 | - | 10 |

E-TLXM1260/100 | 1367.03 | 59.06 | 601.31 | 601.31 | 100.00 | 5.35 |

E-TXLM1800/225 | 2039.04 | 574.8 | 614.12 | 614.12 | 225 | 11 |

Special specification can be produce according to customer requirements.

FAQ

Packaging:

Each roll is wound onto a paper tube which has an inside diameter of 76mm and the roll has a diameter of 275mm. The roll is wrapped up with plastic film,and then packed in a cardboard box or wrapped up with kraft paper. The rolls can be horizontally placed. For transportation, the rolls can be loaded into a cantainer directly or on pallets.

Storage:

Unless otherwise specified, It should be stored in a dry, cool and rain-proof area. It is recommended that the room temperature and humidity should be always maintained at 15℃~35℃ and 35%~65% respectively.

- Q: Is fiberglass mat tissue chemically resistant?

- Indeed, fiberglass mat tissue possesses chemical resistance. Crafted from finely dispersed glass fibers that are haphazardly arranged and held together with a resin binder, this composition endows the material with superb resistance to an extensive array of chemicals, encompassing acids, alkalis, solvents, and oils. It frequently finds utility in sectors like chemical processing, petrochemicals, and wastewater treatment, where encounters with diverse chemicals are prevalent. The chemical resilience of fiberglass mat tissue renders it a fitting selection for applications that necessitate protection against corrosion and long-lasting sturdiness.

- Q: Are there any health risks associated with fiberglass mat tissue?

- Yes, there are some health risks associated with fiberglass mat tissue. Fiberglass contains tiny fibers that when inhaled can irritate the respiratory system and potentially cause lung damage. Prolonged or repeated exposure to fiberglass fibers can also lead to a condition called fiberglass dermatitis, which causes skin irritation and itching. Therefore, proper precautions such as wearing protective clothing and masks should be taken when handling fiberglass mat tissue to minimize the health risks.

- Q: Can fiberglass mat tissue be used for wind turbine nacelles?

- Indeed, wind turbine nacelles can incorporate fiberglass mat tissue. This material, known for its lightweight and durability, finds wide application across various sectors, including the wind energy industry. Its exceptional mechanical properties, such as robustness, stiffness, and resilience against corrosion and fatigue, make it highly suitable for the nacelles of wind turbines. Moreover, fiberglass mat tissue possesses the capability to be easily shaped into intricate forms, rendering it an ideal choice for fabricating the complex components of wind turbine nacelles. In summary, the utilization of fiberglass mat tissue in wind turbine nacelles enhances their structural integrity, reduces their weight, and ultimately improves the overall performance and lifespan of the turbines.

- Q: Does fiberglass mat tissue require any special precautions during storage?

- Yes, fiberglass mat tissue does require some special precautions during storage. Fiberglass is a delicate material and can be easily damaged if not stored properly. Here are some precautions to consider: 1. Keep it dry: Fiberglass mat tissue should be stored in a dry and moisture-free environment. Moisture can cause the material to lose its strength and integrity. 2. Avoid direct sunlight: UV rays from sunlight can degrade fiberglass over time. Store the material in a cool, shaded area away from direct sunlight to prevent any damage. 3. Protect from dust and dirt: Fiberglass mat tissue should be stored in a clean and dust-free environment. Dust and dirt particles can get embedded in the material, making it less effective. 4. Avoid extreme temperatures: Extreme heat or cold can also affect the quality of fiberglass mat tissue. It is best to store it in a temperature-controlled environment to prevent any damage. 5. Use proper packaging: If the fiberglass mat tissue comes with packaging, it is recommended to keep it in its original packaging to provide an additional layer of protection. If not, consider using a durable and moisture-resistant wrapping material. By following these precautions, you can ensure that your fiberglass mat tissue remains in good condition during storage and is ready for use when needed.

- Q: Does fiberglass mat tissue provide good acoustical performance?

- Fiberglass mat tissue does provide good acoustical performance. Due to its composition, which includes fine glass fibers, this material is effective in absorbing sound waves and reducing echo and reverberation in a space. Fiberglass mat tissue has excellent sound absorption properties, making it suitable for applications in various industries such as construction, automotive, and aerospace. Its ability to dampen sound and improve acoustics makes it a popular choice for soundproofing walls, ceilings, and floors in buildings. Additionally, fiberglass mat tissue is lightweight and easy to install, further enhancing its appeal for acoustical applications.

- Q: Is fiberglass mat tissue resistant to fading?

- Fiberglass mat tissue is generally not resistant to fading. Fading occurs when a material loses its original color or brightness due to exposure to sunlight or other environmental factors. While fiberglass itself is known for its durability and resistance to weathering, the mat tissue used in fiberglass products is often susceptible to fading over time. This can be attributed to the binder or resin used to hold the fiberglass fibers together, as well as the pigments or dyes used to color the tissue. Exposure to UV rays and other outdoor elements can cause these components to break down and fade, resulting in a loss of color intensity or brightness. Therefore, if maintaining the aesthetic appearance of a fiberglass product is important, additional protective measures such as applying a UV-resistant coating or using pigments specifically designed for outdoor use may be necessary.

- Q: What is the expected lifespan of fiberglass mat tissue in underground applications?

- Different factors can affect the expected lifespan of fiberglass mat tissue in underground applications. These factors include the conditions of the underground environment, the quality and thickness of the fiberglass mat tissue, and the level of maintenance and care provided. On average, fiberglass mat tissue is known for its durability and longevity, which makes it suitable for use underground. Generally, fiberglass mat tissue is designed to resist corrosion, moisture, and other environmental elements commonly found in underground settings. This makes it a reliable choice for protecting underground pipes, tanks, and other infrastructure from deterioration. When installed correctly and maintained regularly, fiberglass mat tissue can last 50 years or more in underground applications. However, it is important to note that this estimate can vary depending on the specific conditions and usage of the fiberglass mat tissue. To maximize the lifespan of fiberglass mat tissue in underground applications, it is recommended to follow industry best practices. These practices include using proper installation techniques, conducting regular inspections, and promptly addressing any cracks or damage. By following these steps, the lifespan of fiberglass mat tissue can be extended, ensuring long-term reliability and durability underground.

- Q: Is fiberglass mat tissue suitable for aerospace applications?

- Yes, fiberglass mat tissue is suitable for aerospace applications. It is lightweight, has high strength-to-weight ratio, excellent thermal resistance, and is fire-resistant. These properties make it ideal for aerospace components such as insulation, structural panels, and aircraft interiors.

- Q: What are the different finishing options available for fiberglass mat tissue?

- There are several different finishing options available for fiberglass mat tissue. One common finishing option is a resin coating. This involves applying a layer of resin to the surface of the fiberglass mat tissue. The resin helps to protect the fibers and provide added strength and durability. It can also improve the appearance of the material, giving it a smooth and glossy finish. Another finishing option is a fire-retardant treatment. This involves applying a special chemical treatment to the fiberglass mat tissue that helps to reduce its flammability. This is especially important in applications where fire safety is a concern, such as in the construction industry. Additionally, fiberglass mat tissue can be finished with a colored pigment. This involves adding a dye or pigment to the material during the manufacturing process. This allows for a wide range of color options, making the fiberglass mat tissue more visually appealing and versatile. Some manufacturers also offer a textured finish for fiberglass mat tissue. This involves adding a pattern or texture to the surface of the material, creating a more tactile and aesthetically pleasing product. This can be particularly useful in applications where grip or slip resistance is required. Lastly, fiberglass mat tissue can be finished with a laminated backing. This involves bonding the fiberglass mat tissue to a separate backing material, such as foam or fabric. This provides additional strength and flexibility to the material, making it suitable for a wider range of applications. Overall, the different finishing options available for fiberglass mat tissue allow for customization and adaptation to specific needs and requirements. Whether it's adding strength, fire resistance, color, texture, or additional backing, these finishing options enhance the performance and appearance of fiberglass mat tissue in various industries.

- Q: Can fiberglass mat tissue be used for repairing fiberglass canoes?

- Indeed, fiberglass canoes can be repaired using fiberglass mat tissue. This lightweight material is typically employed to reinforce fiberglass structures, and it is frequently utilized in the realm of boat repairs due to its ability to enhance strength and durability in the mended region. The mat tissue is specifically crafted to be effortlessly molded and shaped, rendering it ideal for rectifying curved surfaces like canoes. Furthermore, fiberglass mat tissue harmonizes with commonly used polyester and epoxy resins in fiberglass repairs. Consequently, it is a fitting substance for the restoration of fiberglass canoes, effectively reinstating the structural integrity of the afflicted portions.

Send your message to us

Fiberglass Mat Tissue Stitched Mat Triaxial for FRP Application

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 kg

- Supply Capability:

- 100000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords