Chopped Fiberglass Strands 1 Fiberglass Powder Chopped Stand Mat General Purpose

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Quick Details

| Technique: | Chopped Strand Fiberglass Mat (CSM) | Dimensions: | 450gsm | Mat Type: | Continuous Filament Mat |

| Fiberglass Type: | E-Glass | Softness: | softness | Place of Origin: | Jiangxi, China (Mainland) |

| Brand Name: | cnbm | Model Number: | 450gsm | color: | white |

| fiberglass type: | E glass | product: | e-glass powder chopped stand mats | binder: | powder or emulsion |

| width: | 1040 or 1270mm, as your requirement | weight: | 30 or 45kg/roll | paper tube diameter: | 90mm |

| outer diameter of roll: | 256mm | packing: | plastic film+carton box + pallet |

Packaging & Delivery

| Packaging Details: | plastic film+carton box + pallet |

| Delivery Detail: | 15-20days |

Specifications

1.e-glass powder chopped stand mats

2.binder:power or emulsion

3.width:1040mm or 1270mm

4.weight:450gsm

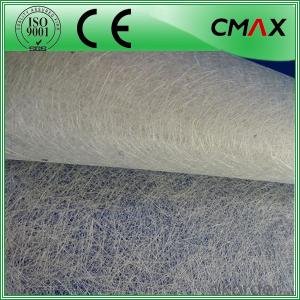

Picture

- Q: What is the difference between the ferte and shortcoming of the carbon fiber?

- Basically it does not increase the component section, and the increase of the self weight of structures can be ignored, which can ensure it can work with the original reinforced concrete members together and get good reinforcing effect. It is widely used in building structure reinforcement. 2 convenient construction: It boasts less occupied site, no need of large machines, no construction, no fire, no fixed site facilities, high construction efficiency. 3 high durability: It does not rust, and is very suitable for using in high acid, alkali, salt and corrosion environment. Also it has the ferte of high anti fatigue strength, wear resistance, anti-aging, etc.. The characteristics of carbon fiber composite material is a lightweight and high-strength, but processing is difficult. There are great differences among the carbon fiber production which adapt difernent technology, so as to the differences between different trade marks. But it certainly is in terms of strength, toughness and corrosion resistance are higher than the Aluminum Alloy steel and carbon fiber products. Once the damage is hard to repair, such as a piece of carbon fiber composite plate cracking, it must be replaced by a whole plate, but it can not be repaired by welding and other ordinary methods.

- Q: Aluminum paste carbon fiber glass fiber pulp slurry canoeing and what is the difference between what are the benefits of

- Carbon fiber solid material, high tensile strength, light weight and good quality, but the impact resistance and less expensive; glass fiber material in the performance was not as good as carbon fiber, but also tensile stretch, good durability, light weight, moderate price; aluminum elasticity is relatively poor, but the price is cheaper.

- Q: What are the acoustic insulation properties of fiberglass chopped strand?

- Due to its unique composition and structure, fiberglass chopped strand possesses exceptional acoustic insulation properties. Comprised of fine glass fibers that are randomly arranged and bound together with a resin or binder, the chopped strands form a dense and fibrous structure that effectively absorbs sound waves. The main way in which fiberglass chopped strand provides acoustic insulation is by diminishing sound transmission. When sound waves collide with the surface of the fiberglass, they are converted into mechanical vibrations, which are then absorbed and dispersed within the fibrous structure. Through this absorption process, the material significantly reduces the amount of sound that passes through it, resulting in a quieter environment. Moreover, the dense and fibrous nature of fiberglass chopped strand helps to dampen and lessen sound. The numerous air pockets and interlocking fibers within the material create a high level of internal friction, which effectively dissipates sound energy. This not only reduces the intensity of sound but also helps to prevent the transmission of vibrations and resonance. Furthermore, fiberglass chopped strand is renowned for its outstanding thermal insulation properties, which indirectly contribute to acoustic insulation. The material's ability to resist heat transfer helps maintain a consistent temperature, thereby reducing the occurrence of sound-reflecting surfaces and minimizing the amplification of noise. In conclusion, fiberglass chopped strand is an exceptionally efficient material for acoustic insulation. Its dense and fibrous structure, combined with its capacity to absorb, dampen, and attenuate sound waves, make it an ideal choice for applications requiring noise reduction and control, such as in construction, automotive, and industrial settings.

- Q: Can fiberglass chopped strand be used in aerospace interior components?

- Fiberglass chopped strand is indeed applicable for aerospace interior components. This lightweight and versatile material possesses exceptional strength and durability, making it widely utilized across various industries, including aerospace. The aerospace sector demands interior components that are both lightweight and capable of withstanding the rigorous conditions of flight. Fiberglass chopped strand fulfills these requirements, as it is lightweight and boasts high tensile strength. It finds extensive use in the production of panels, seat backs, overhead bins, and cabin partitions. Notably, fiberglass chopped strand exhibits exceptional fire resistance properties, which are of utmost importance in aerospace applications. It successfully adheres to the stringent fire safety regulations and standards set by aviation authorities. Moreover, the processing of fiberglass chopped strand is relatively straightforward, ensuring efficient and cost-effective manufacturing processes. It can be molded into diverse shapes and sizes, making it ideal for intricate aerospace interior designs. In summary, fiberglass chopped strand is an ideal material for aerospace interior components due to its lightweight nature, high strength, fire resistance, and ease of processing. Its utilization in the aerospace industry contributes to the safety, performance, and comfort of both passengers and crew members during flights.

- Q: Is fiberglass chopped strand compatible with melamine resin?

- Yes, fiberglass chopped strand is compatible with melamine resin.

- Q: Production and process of glass fiber

- The process of glass fiber generally includes: Purchase raw materials, mix according to the formula, and then transferred to the glass furnace for melting and refining, after operation channel flow to the bushing, the sizing agent after coating by wire drawing machine traction, then form the original cake, and then flow to the rear section reprocessing procedures (usually a short cut, winding, weaving, puffing and twisting) or sell (direct yarn)

- Q: How does the fiber dispersion distribution of fiberglass chopped strand affect the properties of composites?

- The fiber dispersion distribution of fiberglass chopped strand plays a crucial role in determining the properties of composites. The distribution affects the strength, stiffness, and overall performance of the composite material. A uniform and well-dispersed distribution of fibers can enhance the mechanical properties, such as tensile strength and impact resistance. It also improves the load-bearing capability and dimensional stability of the composite. On the other hand, an uneven or poor fiber dispersion distribution can lead to weak spots, reduced strength, and potential failure under stress. Therefore, achieving a consistent and optimal fiber dispersion distribution is essential to ensure the desired properties and performance of composites.

- Q: How does the fiber aspect ratio affect the performance of fiberglass chopped strand?

- The fiber aspect ratio plays a crucial role in determining the performance of fiberglass chopped strand. It refers to the ratio of the length to the diameter of the fiber. When the aspect ratio is higher, it means that the fiber length is relatively longer compared to its diameter. This aspect ratio is important for determining the mechanical properties of the chopped strand. Fiberglass with a higher aspect ratio tends to have better mechanical strength and stiffness. The longer fibers provide enhanced reinforcement and improve the overall performance of the composite material. The aspect ratio also affects the interfacial bonding between the fiber and the matrix material in a composite. A higher aspect ratio allows for a larger surface area for the fiber to interact with the matrix. This results in improved adhesion and bonding, which in turn enhances the mechanical properties of the composite. Furthermore, a higher aspect ratio can also contribute to the improved dispersion of the chopped strand within the matrix. Longer fibers disperse more evenly, leading to a more homogeneous composite structure. This uniform dispersion helps in reducing potential weak spots or areas of stress concentration, thereby improving the overall performance and durability of the composite material. On the other hand, a lower aspect ratio indicates that the fiber length is relatively shorter compared to its diameter. While lower aspect ratio fibers may still provide some reinforcement to the composite, their mechanical properties are generally not as strong as those with higher aspect ratios. They may not offer the same level of strength, stiffness, and impact resistance. In summary, the fiber aspect ratio has a significant impact on the performance of fiberglass chopped strand. Fibers with a higher aspect ratio provide better mechanical properties, enhanced interfacial bonding, and improved dispersion within the composite matrix, resulting in a stronger and more durable composite material.

- Q: How does the fiber alignment of fiberglass chopped strand affect its flowability?

- The fiber alignment of fiberglass chopped strand significantly affects its flowability. When the fibers are aligned in a parallel or unidirectional manner, the flowability of the chopped strand is enhanced. This is because the aligned fibers create a more streamlined flow path, allowing the resin to flow more easily around them. On the other hand, if the fibers are randomly oriented or tangled, the flowability is reduced as the resin encounters more resistance due to the entangled fibers. Hence, the fiber alignment plays a crucial role in determining the flowability of fiberglass chopped strand.

- Q: Make 0.3 mm glass fiber short cut. What kind of fiberglass yarn is good?

- The glass is made of glass fiber chopped after melting, with high-speed airflow or flame blow it into thin and short fiber, which became a moisture-proof glass wool. Superfine glass wool, more than 200 together only a hair so rough. Glass cotton has strong thermal insulation properties. 3 cm thick glass wool insulation, its ability to compete is equivalent to 1 meters thick brick! Glass wool sound-absorbing effect is also very good. So it is used as insulation, in many industrial sectors in sound insulation, heat insulation, shockproof and filtration materials.

Send your message to us

Chopped Fiberglass Strands 1 Fiberglass Powder Chopped Stand Mat General Purpose

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords