Fiberglass Mat Tissue E-Glass Fiberglass Woven Roving 400g 1270mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

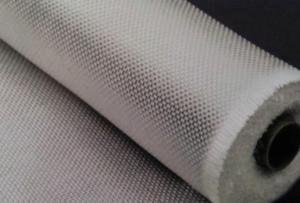

Structure of woven roving Description

1,high strenth,corosion and resistence

2,consistent thickness,no fuzz

3,rapid impregnating

Glass woven rovings are bidirectional fabric by direct rovings in plain weave pattern. They are applicable for hand lay-up, winding and compress molding process, suitable for manufacturing tank, boat, automobile parts and other FRP products.

Main Features of the woven roving

1)Drapes well to suit the surface of intricate moulds

2)Fast wet-through and wet out

3)Easy handing and better appearance of the composite parts

4)Compatible with Unsaturated polyester resin

5)Very high laminate strength properties

Woven roving Images

Woven roving Specification:

Normal type | EWR800 | EWR400 | EWR300 | EWR500 | EWR600 |

Thickness (mm) | 0.8 | 0.4 | 0.3 | 0.5 | 0.6 |

Density(warpxweft) (end/cm) | 1.8x1.5+/-10% | 3.6x3.2+/-10% | 4.6x4.1+/-10% | 2.2X2.0+/-10% | 2.6X2.4+/-10% |

Tex (warpxweft) | 2400x2400 | 600X600 | 300x400 | 1200x1200 | 1200X1200 |

Moisture content(%) | <0.2% | <0.2% | <0.2% | <0.2% | <0.2% |

Loss on ignition(%) | 0.4 – 0.8 | 0.4-0.8 | 0.4-0.8 | 0.4-08 | 0.4-0.8 |

Width(cm) | 125+/-1 | 125+/-1 | 125+/-1 | 125+/-1 | 125+/-1 |

Weight (g/m2) | 816+/-41 | 408+/-32 | 300+/-15 | 500+/-25 | 600+/-30 |

Weight per roll(kg) | 45 | 46 | 50 | 45 | 45 |

Glass | E-glass | E-glass | E-glass | E-glass | E-glass |

FAQ of woven roving:

Delivery Detail: 15-21days

Other spec. can be custom made as per customer's request.

- Q: Can fiberglass mat tissue be used for flooring insulation?

- Typically, fiberglass mat tissue is not employed for flooring insulation. It is a lightweight substance frequently utilized in the construction sector to reinforce plaster and concrete, and as insulation in walls and ceilings. However, for flooring insulation purposes, other materials like foam boards or batt insulation are generally favored. These materials offer superior thermal and sound insulation features that are specifically tailored for flooring applications. Moreover, they are simpler to install and better equipped to endure the pressures and demands of foot traffic on the flooring.

- Q: What are the factors that affect the diameter of electrospun nanofibers?

- High efficiency air filter, air filter (HEPA filter) is widely applied to the requirements of clean and sterile room (electronic goods and drug manufacturing sites, operation room) and other applications (such as air purifiers, vacuum bag filter and mask). Superfine glass fiber mat, melt blown (MB) fiber network, electrospun fiber mesh and ePTFE film and other media can reach...

- Q: How is fiberglass mat tissue used in the construction industry?

- Fiberglass mat tissue is widely used in the construction industry for various applications. This material is made up of thin strands of glass fibers that are bonded together with a resin. It offers several properties that make it suitable for construction purposes. One common use of fiberglass mat tissue is in the production of roofing materials. It is often used as a reinforcement layer in roofing shingles or sheets. The fiberglass mat tissue adds strength and durability to the roof, making it more resistant to weather elements such as wind, rain, and hail. Additionally, it helps to prevent cracking and splitting, prolonging the lifespan of the roofing material. Another application of fiberglass mat tissue in the construction industry is in the production of composite materials. It is commonly used as a reinforcement layer in composite panels and boards. The fiberglass mat tissue enhances the strength and stiffness of the composite material, making it suitable for various structural applications. It is also lightweight, which makes it an ideal choice for building materials that require both strength and reduced weight. Fiberglass mat tissue is also used in the construction of walls and ceilings. It can be applied as a layer between the gypsum board and the insulation material to provide additional strength and resistance to impacts. This helps to prevent cracks and damage to the walls or ceilings, enhancing the overall structural integrity of the building. Furthermore, fiberglass mat tissue finds application in the construction of pipes and tanks. It is used as a reinforcement layer in the manufacturing of fiberglass-reinforced plastic (FRP) pipes and tanks. The fiberglass mat tissue adds strength and rigidity to the FRP structure, making it suitable for various industrial applications, including chemical processing, wastewater treatment, and oil and gas industries. In conclusion, fiberglass mat tissue is widely used in the construction industry for its strength, durability, and lightweight properties. It is utilized in roofing materials, composite panels, walls, ceilings, pipes, and tanks, among other applications. Its versatility and performance make it a preferred choice among construction professionals for enhancing the structural integrity of various building components.

- Q: How long does fiberglass mat tissue typically last?

- The lifespan of fiberglass mat tissue can vary depending on various factors such as the quality of the material, its exposure to environmental conditions, and the level of maintenance. On average, fiberglass mat tissue can last anywhere from 20 to 30 years. However, with proper installation and regular upkeep, it is possible for it to last even longer. It is important to note that regular inspection and maintenance can help identify any signs of wear or damage, allowing for timely repairs or replacements to ensure its longevity.

- Q: Can fiberglass mat tissue be used for insulation in chemical storage tanks?

- Yes, fiberglass mat tissue can be used for insulation in chemical storage tanks. It is a commonly used material due to its excellent thermal insulation properties and resistance to corrosion, making it suitable for protecting the tank and its contents from extreme temperatures and chemical reactions.

- Q: What are the different thickness tolerances for fiberglass mat tissue?

- The different thickness tolerances for fiberglass mat tissue can vary depending on the specific manufacturer and product specifications. However, in general, fiberglass mat tissue is available in various thickness tolerances ranging from 0.5 millimeters (mm) to 3 mm. The tolerance refers to the acceptable range of thickness variation within a certain product. For example, a fiberglass mat tissue with a thickness tolerance of +/- 0.5 mm means that the actual thickness of the tissue can vary by up to 0.5 mm in either direction from the specified thickness. The specific tolerance required for a particular application depends on the intended use and the level of precision needed. Thicker fiberglass mat tissues with smaller tolerances are often used in applications that require higher strength and durability, such as in the construction industry for reinforcing concrete or in the manufacturing of composite materials. On the other hand, thinner fiberglass mat tissues with larger tolerances may be used in applications where flexibility and conformability are more important, such as in the automotive industry for insulation or soundproofing purposes. It is important to consult the manufacturer's specifications or contact a supplier for accurate information on the available thickness tolerances for fiberglass mat tissue, as they can vary significantly depending on the specific product and supplier.

- Q: Can fiberglass mat tissue be used for insulating exterior walls?

- Yes, fiberglass mat tissue can be used for insulating exterior walls. Fiberglass mat tissue is a type of insulation material that is commonly used for its excellent thermal and acoustic insulation properties. It is made of fine glass fibers that are bonded together with a binder, creating a flexible and lightweight material. When used for insulating exterior walls, fiberglass mat tissue is typically installed between the wall studs or in the wall cavities. It helps to reduce heat transfer by trapping air within its fibers, which acts as a barrier against heat loss or gain. This insulation material can significantly improve the energy efficiency of a building by reducing the need for heating or cooling, thereby reducing energy costs and carbon emissions. Fiberglass mat tissue is also resistant to moisture, mold, and mildew, making it suitable for exterior applications. It helps to create a more comfortable and healthier indoor environment by preventing the growth of harmful microorganisms and reducing condensation. Additionally, fiberglass mat tissue is fire-resistant, adding an extra layer of safety to the building. Overall, fiberglass mat tissue is a versatile and effective insulation material that can be used for insulating exterior walls. Its thermal, acoustic, moisture resistance, and fire-resistant properties make it an excellent choice for improving the energy efficiency and comfort of buildings.

- Q: Does fiberglass mat tissue require any special tools for installation?

- Special tools may be needed for installing fiberglass mat tissue. These tools may include a utility knife or scissors for cutting the mat to the desired size, a roller or brush for applying adhesive or resin to secure the mat to the desired surface, and safety equipment like gloves and goggles to protect the installer from potential dangers. Furthermore, certain installations may necessitate the use of a heat gun or torch to activate or cure the resin. To ensure proper installation and ascertain if any special tools are necessary, it is crucial to carefully read and adhere to the manufacturer's instructions and recommendations for the specific fiberglass mat tissue being used.

- Q: Can fiberglass mat tissue be used for repairing fiberglass surfboards?

- Yes, fiberglass mat tissue can be used for repairing fiberglass surfboards. It is a common material used in surfboard repairs as it provides added strength and stability to damaged areas.

- Q: How does fiberglass mat tissue perform in terms of moisture vapor resistance?

- Fiberglass mat tissue is generally effective at resisting moisture vapor. It acts as a barrier, preventing the passage of water vapor and making it suitable for moisture control in applications like roofing and insulation. To enhance the moisture vapor resistance of fiberglass mat tissue, it can be combined with other materials like vapor barriers or moisture-resistant coatings. These additional layers provide extra protection against moisture infiltration, improving the overall performance of the fiberglass mat tissue. However, it should be noted that the moisture vapor resistance of fiberglass mat tissue can vary depending on factors such as thickness, density, and composition. Thicker and denser mats tend to offer higher resistance, while the presence of manufacturing additives or coatings can also affect the material's properties. In conclusion, fiberglass mat tissue is known for its moisture vapor resistance, but its performance may be influenced by various factors. It is recommended to consult product specifications or manufacturers' recommendations to determine the specific moisture vapor resistance of a particular fiberglass mat tissue product.

Send your message to us

Fiberglass Mat Tissue E-Glass Fiberglass Woven Roving 400g 1270mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords