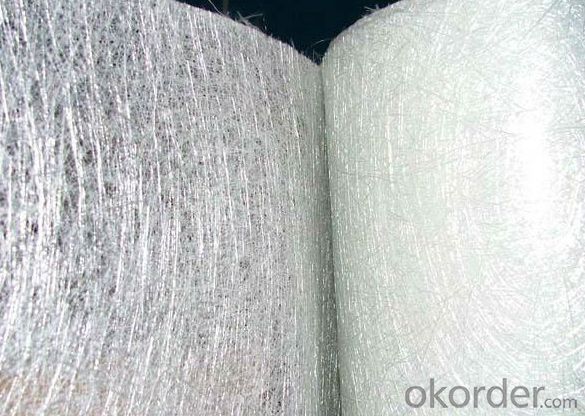

Fiberglass Mat Tissue e-glass Chopped Strand Mat 3200mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- 10000MT m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Breif Introduction

Chopped strand mat with width 3200mm

2.Main Features

Our chopped strand mat is with width 3200mm, packing in wooden box (pallet)with width 3250mm. In each 40HQ can be loaded 16-18 boxes(pallets), qualitu is around 2000kgs in each container.

Standard Specifications for Chopped strand mat

1. High quality

2. ISO9001, 2008 quality controled

3. 320cm width, 100g,300g,450gto 900g

Our chopped strand mat factory specializes in manufacturing E-glass Chopped strand Mat (chopped strand mat manufacturer). The products range from chopped strand mat 300g/m2, chopped strand mat 450g/m2 to chopped strand mat 600g/m2 and 900g, the width from 102cm,104cm,125cm to 320cm.

3.Specifications

Product code | Glass type | Unite weight (g/m2) | Width(mm) | Roll weight (kg) | Moisture (%) | Binder content (%) |

100 | E Glass | 100+/-20 | 200-3200 | 30-70 | <0.2-0.3 | 3-4 |

150 | E Glass | 150+/-20 | 200-3200 | 30-70 | <0.2-0.3 | 3-4 |

200 | E Glass | 200+/-20 | 200-3200 | 30-70 | <0.2-0.3 | 3-4 |

300 | E Glass | 300+/-20 | 200-3200 | 30-70 | <0.2-0.3 | 3-4 |

| 450 | E Glass | 450+/-20 | 200-3200 | 30-70 | <0.2-0.3 | 3-4 |

600 | E Glass | 600+/-20 | 200-3200 | 30-70 | <0.2-0.3 | 3-4 |

900 | E Glass | 900+/-20 | 200-3200 | 30-70 | <0.2-0.3 | 3-4 |

4.FAQ

Q: Which knid of payment terms can you accept?

A: We can accept 30% prepayment, 70% payment before shippment. LC is also accepted

- Q: Is fiberglass mat tissue compatible with different curing methods?

- Yes, fiberglass mat tissue is compatible with different curing methods. It can be cured using various methods, such as wet lay-up, resin infusion, and vacuum bagging. The mat tissue can be impregnated with different types of resins, including polyester, epoxy, and vinyl ester, allowing it to be used in a wide range of applications and cured using the appropriate method for each specific resin system.

- Q: Are there any environmental considerations when using fiberglass mat tissue?

- Yes, there are several environmental considerations when using fiberglass mat tissue. Firstly, the production of fiberglass mat tissue involves the use of energy and resources. The manufacturing process requires the extraction of raw materials, such as silica sand, limestone, and soda ash, which are non-renewable resources. The energy-intensive process of melting these materials at high temperatures also contributes to greenhouse gas emissions. Additionally, the production of fiberglass involves the use of chemicals, such as resins and binders, which can be harmful to the environment if not properly managed. These chemicals can potentially leach into water bodies or soil if not handled and disposed of correctly. Furthermore, fiberglass mat tissue is not biodegradable. Once it reaches the end of its lifespan, it can take hundreds of years to break down in a landfill. Improper disposal of fiberglass mat tissue can lead to environmental pollution and contribute to the growing problem of waste management. Lastly, the use of fiberglass mat tissue in certain applications, such as insulation or construction, can have energy efficiency implications. While fiberglass is an effective insulator, its production and installation may require additional energy inputs, such as the use of fossil fuels for transportation or heating during installation. To mitigate these environmental considerations, it is important to promote sustainable practices in the production and use of fiberglass mat tissue. This can include implementing energy-efficient manufacturing processes, reducing the use of harmful chemicals, promoting recycling or reuse of fiberglass materials, and exploring alternative materials that have a lower environmental impact.

- Q: Can fiberglass mat tissue be used for insulation in chemical storage tanks?

- Yes, fiberglass mat tissue can be used for insulation in chemical storage tanks. It is a commonly used material due to its excellent thermal insulation properties and resistance to corrosion, making it suitable for protecting the tank and its contents from extreme temperatures and chemical reactions.

- Q: Can fiberglass mat tissue be used for making lightweight ceilings?

- Yes, fiberglass mat tissue can be used for making lightweight ceilings. It is a strong and lightweight material that is commonly used in construction for its fire resistance, durability, and insulation properties. It can be easily molded and shaped to create lightweight ceiling panels, making it an ideal choice for applications where weight reduction is desired.

- Q: Can fiberglass mat tissue be used for making furniture?

- No, fiberglass mat tissue is not suitable for making furniture. It is primarily used in composite materials and construction applications, not for furniture manufacturing.

- Q: Is fiberglass mat tissue suitable for insulation in educational facilities?

- Yes, fiberglass mat tissue is suitable for insulation in educational facilities. It offers excellent thermal insulation properties, is easy to install, and provides effective soundproofing. Additionally, it is fire-resistant, durable, and cost-effective, making it a practical choice for educational buildings.

- Q: How does fiberglass mat tissue perform in terms of mold and mildew resistance?

- Fiberglass mat tissue possesses exceptional mold and mildew resistance. Its inherent moisture resistance prevents the proliferation of mold and mildew. Moreover, fiberglass is impermeable and unsuitable for the flourishing of these microorganisms. Furthermore, fiberglass mat tissue finds extensive usage in areas with high humidity, like bathroom walls or showers, and has proven highly efficient in deterring mold and mildew growth. All in all, fiberglass mat tissue exhibits outstanding performance in terms of mold and mildew resistance, rendering it a dependable option for situations where these issues are prominent.

- Q: Can fiberglass mat tissue be used for automotive parts?

- Yes, fiberglass mat tissue can be used for automotive parts. Fiberglass mat tissue is a versatile material that provides strength, rigidity, and durability. It is commonly used in the automotive industry for various applications such as reinforcing panels, bumpers, hoods, and body parts. The fiberglass mat tissue is lightweight, making it suitable for reducing the overall weight of the vehicle and improving fuel efficiency. Additionally, it is resistant to corrosion, chemicals, and extreme temperature conditions, making it a reliable choice for automotive parts. The material's flexibility also allows for easy molding and shaping, enabling manufacturers to create complex designs and achieve desired aesthetics. Overall, fiberglass mat tissue is an excellent option for automotive parts due to its strength, durability, lightweight nature, and versatility.

- Q: What is the flexural strength of fiberglass mat tissue?

- The flexural strength of fiberglass mat tissue refers to its ability to resist bending or flexing without breaking. It is typically high due to the reinforcing properties of the fiberglass material, making it suitable for applications requiring structural integrity and resistance to deformation.

- Q: What is the expected lifespan of fiberglass mat tissue in sports facility applications?

- The expected lifespan of fiberglass mat tissue in sports facility applications can vary depending on various factors such as the quality of the material, the level of maintenance and care, and the specific conditions in which it is used. However, generally speaking, fiberglass mat tissue has a relatively long lifespan and is known for its durability. When properly installed and maintained, fiberglass mat tissue can last for several decades. It is resistant to corrosion, rot, and degradation, making it suitable for use in sports facilities where it may be exposed to moisture, humidity, and other environmental factors. To maximize the lifespan of fiberglass mat tissue in sports facility applications, regular inspections, cleanings, and repairs may be necessary. It is also important to follow manufacturer recommendations for installation and maintenance to ensure optimal performance and longevity. It is worth noting that while fiberglass mat tissue is known for its durability, it may still experience wear and tear over time, especially in high-impact areas or in facilities with heavy usage. In such cases, periodic replacements or repairs may be required to maintain the integrity and functionality of the material. Overall, fiberglass mat tissue is a reliable and long-lasting option for sports facility applications, and with proper care and maintenance, it can provide excellent performance and durability for many years.

Send your message to us

Fiberglass Mat Tissue e-glass Chopped Strand Mat 3200mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- 10000MT m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords