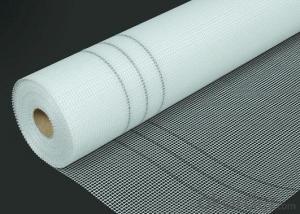

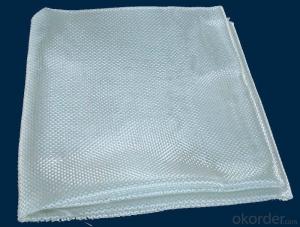

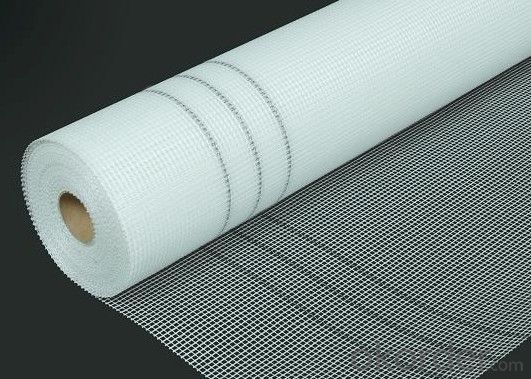

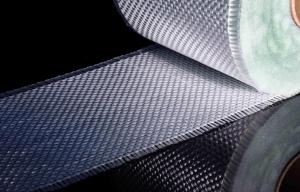

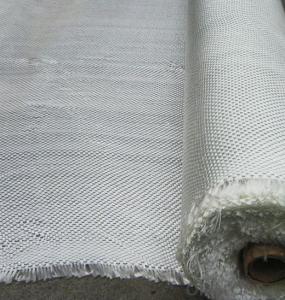

Fiber Glass is Woven by Glass Fibers/Plain Woven/mainly used as banding tapes for insulation

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t

- Supply Capability:

- 500 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Place of Origin: | Henan, China (Mainland) | Brand Name: | cnbm | Model Number: | FG60-300g/m2 |

| Application: | Wall Materials | Weight: | 60,75,90,110,125,145,160g | Width: | 1m,16.6cm |

| Mesh Size: | 4x4,5x5,10x10mm | Weave Type: | Plain Woven | Yarn Type: | E-Glass |

| Alkali Content: | Medium | Standing Temperature: | 300 | item: | Fiberglass mesh |

| Certificate: | ISO9001:2000 | Europe Certificate: | ETAG | Glue coating: | Acrylic acid 16-18% |

| Weave type: | Leno | high strength mesh: | fireproof mesh | soft mesh: | hard and medium hard mesh |

Packaging & Delivery

| Packaging Details: | packed in shrink film then packed in carton with pallet or without pallet.30 rolls/carton or 6 rolls/carton. 75g/m2, 170000m2/40'HC. 145g/m2, 110000m2/40'HC.160g/m2, 110000/40'HC. |

| Delivery Detail: | delivery 1X20GP' in abt 8 days after order |

Specifications

1)Supply CE,ITB,ISO9001

2)Help customer avoiding anti-dumping duty

3)Platinum glass fiber roving

4)Acrylic glue content 16-20

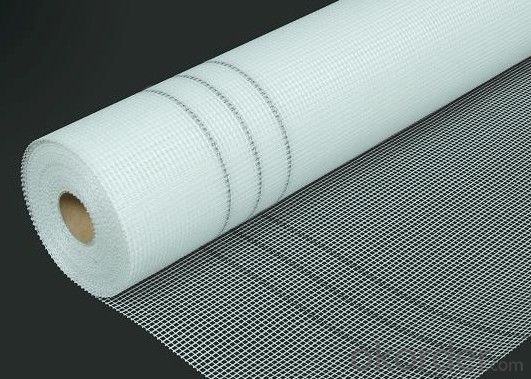

Fiberglass mesh is woven by platinum fiberglass yarn and then treated with acrylic glue. It has fine alkaline-resistant, high strength, etc. As an ideal engineering material in construction, fiberglass mesh is mainly used to reinforce cement, stone, wall materials, roofing, bitumen, gypsum, waterpoof and so on.

Fiberglass mesh high quality ability:

1) warp and weft of mesh is very straight, also bright surface.

2) Coating enough alkaline resistant glue and keep 60% - 80% strength after testing in Naoh 28 days later

3) Made by C-glass fibers woven roving as basis material, and then treated with acrylic acid copolymer liquid, glue content:14-18%

4) High tensile strength, the mesh is not easy be teared.

5) Small sample free

Main specs:

5mm x 5mm/75g/m2, 90g/m2, 125g/m2, 145g/m2, 160g/m2,etc.

4mm x 4mm/75g/m2, 90g/m2, 110g/m2,125g/m2, 135g/m2, 145g/m2, 160g/m2, etc.

10mm x 10mm/90g/m2, 110g/m2, 125g/m2, 135g/m2. 145g/m2, 150g/m2,160g/m2,etc.

2.85mm x 2.85mm/60g/m2, 75g/m2,etc

plain weave : 10X20mesh/inch:60g/ m2,etc

Packing

Inner packing: shrinkage packing one roll ,then 30 to 52 rolls/pallet or 4 rolls/carton

We get ISO9001:2000, ITB and Europe ETAG certificate.

- Q: What is the thermal insulation material of glass wool?

- It is a cotton-like material which has advantages of low thermal conductivity, chemical stability, good sound absorption. The glass wool is an inorganic fiber which has a excellent welding performance. Glass wool which is a man-made inorganic fiber fiberizes melten glass, it is a insulation material that has advantages of corrosion resistance, thermal insulation and small bulk density. I tell you that it belongs to glass in terms of chemical composition: The thermal insulation material, glass wool belongs to glass fiber.

- Q: Now what is the latest color steel sandwich board? such as: Foam, stretches, glass wool

- Foam is the mainly material, now with the increase of rock wool, the rock wool can be fireproofing and sound absorption, it may also lay glass wool in the interior of color steel?plate and the function is sound absorption and thermal insulation.

- Q: What environmental pollutions will be created during the production of glass wool?

- It is quite dangerous. Glass wool is very small, such as phenol. If it gets into lungs,the health hazards in the exhaust gas are harmful. If it is on the skin, it will be atingle and itchy. During the production of glass wool, there will be formaldehydes and glass fiber dust.

- Q: Centrifugal glass wool board and flexible foam rubber insulation, which one is better?

- Glass wool board has good fireproof performance and can endure higher temperature than the rubber material, which is cheap. Rubber material has poor fireproof performance. It has insulation performace no better than other materials.

- Q: What harm dose glass fiber cotton do to human body?

- It may cause great harm to eyes and mucosa. Workers who are exposed to glass fiber for a long time may contract contact dermatitis, but some workers can gradually endure it, which is known as "hardening phenomenon".The degree of skin damage depends on fiber diameter and roughness of surface. For now it is widely recognized that only when the diameter exceeds 5μm, the fibre will be obviously irritative.Few workers who contact glass fiber and rock wool have skin allergies, but so far these fibers have not been confirmed to be sensitinogen.

- Q: Which is the more commonly used thermal insulation material between thermal insulation glass?silk wool and rock wool?

- Glass wool: Glass wool has no shots, having less dust and little irritation to skin and respiratory system as well as light weight, able to be processed to products with long length based on design requirements. It entails less waste, easy to construction. It uses amorphous cellulose which is soft and lathy with no shots, able to serve for more than 20 years. So, in terms of price per ton, rock wool is cheaper than glass wool. But in terms of price per square meter, the prices of glass wool and rock wool are basically flat. If various factors like effect, construciton, service life, safety and bearing structure are took into account comprehensively, glass wool then is more economical. Rock wool: It contains a high content of shots and much dust. It is high irritable to skin and respiratory system, keeping heavy weight, so it cannot be processed for a long time. It entails much waste, difficult to construction. It uses crystalline fiber, which has a high content of shots, is shoyt and unstable. If used for a certain time, its shots and short?fiber will sink, making it unable to maintain a uniform shape, which will seriously affect the insulation effect and needs to be replaced consequently. And the replacement cycle is shorter than 10 years.

- Q: Which kind of soundproof cotton is the best for decorative gypsum board partition ? Mineral rock wool or glass wool?

- Of course, they are very profitable in China, which is asbestos material. American Armstrong's failure is such an example. You can search the hazards of asbestos online. While glass wool is much better.

- Q: What are the hardnesses of rock wool and glass wool respectively? Are there any requirements on saw blade?

- I do not know about the hardness, but I know that ordinary hacksaw is enough. I'm sorry, I don't have calculation parameters.

- Q: What is the density of glass wool?

- Glass wool, a man-made inorganic fiber, belongs to a kind of glass fiber. It is a spongiform material made through fibration of melten glass. It is an inorganic fiber whose chemical components belong to glass, having good formability, low bulk density, low thermal conductivity, good thermal insulation and sound absorption, corrosion resistance and chemical stability. For centrifugal glass wool whose thickness exceed 5 cm and unit weight is 16Kg / m3, the sound absorption coefficient of low frequency125Hz is about 0.2, and that of middle and high frequency is close to 1. When the thickness continues to increase from 5cm, the low-frequency sound absorption coefficient also increase gradually. When the thickness is greater than 1m or more, 125Hz low frequency sound absorption coefficient will also be close to 1. Thicknesses of acoustic glass wools often used in architectural acoustics are 2.5cm, 5cm, 10cm, and unit weights are16,24,32,48,80,96,112kg / m3. centrifugal glass wool whose thickness is 5 cm and unit weight is 12-48kg / m3 is usually used.

- Q: Why does glass wool turn black when exposed to heat? Wether it will ffect the thermal insulation effect.

- The burning like alcohol lamp uses glass wool as the substrate. There are two possibilities to take alcohol lamp to do experiment, which containing organic substances. 2. 1, High temperature oxidation. I produce aerogel thermal insulation felt, and I have seen that the charcoal ash produced is attached to the glass wool. It has some impact on thermal insulation effect, but the impact is small.

Send your message to us

Fiber Glass is Woven by Glass Fibers/Plain Woven/mainly used as banding tapes for insulation

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t

- Supply Capability:

- 500 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches