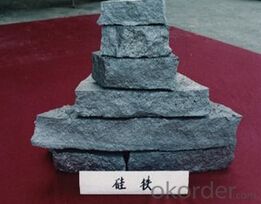

FeSi Inoculant Used In Steel Making

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

1.Fesi inoculant

2.excellent deoxidizer

3.Used in steeling making

4.strict quality control

5.free sample

Ferro silicon Inoculant

Fesi inoculant

An extensive range of ferro silicon inoculants are available with various combinations of active inoculating elements including Barium, Calcium.

Specs of Inoculants

Inoculant Grade | Chemical Composition (%) | |||||

Si | Ba | Ca | Al | Fe | ||

Si-Ba | MRB-1 | 68-72 | 1-3 | 0.5-1.5 | 1.5max | Balance |

MRB-2 | 60-65 | 4-6 | 1-2 | 1.5max. | Balance | |

MRB-3 | 60-65 | 2-4 | 2-4 | 1.5max | Balance | |

MRB-4 | 55-60 | 10-15 | 1-2 | 1.5max | Balance | |

FeSi | MRSi-1 | 72-75 |

|

| 1.5max | Balance |

MRSi-2 | 65-70 |

|

| 1.5max | balance | |

Purpose of Ferro Silicon Inoculant

1)improve the homogeneity of the cast iron structure

2)eliminate the formation of carbides into thin parts or salient angles

3)direct the solidification towards the stable diagram, with graphite precipitation

4)refine the structure (higher cells count, finer grains in the microstructure)

5)improve mechanical properties

6)better separate slag and metal

7)decrease the tendency to dross formation

8)decrease tendency of micro-shrinkage

9)decrease risk of gas formation

10)decrease risk of mold / metal interface defects

FACTORY:

- Q: CNC alloy milling cutter how to produce?What is the cutting edge of the machine tool?What is the surface coating?What is the cost of plating?Prawns talk about it in detail, I do alloy accessories, I would like to learn some processing methods ~ ~!

- CNC carbide cutter is used to hard alloy powder and powder metallurgy mould after sintering, the hard alloy blade (blank, can not be directly used), then after grinding the surface and edge (this can be installed on the cutter head, and also can be used) in coating the surface to improve its wear resistance, have finished milling blade.The blade is machined with a special blade grinder. The price varies from a few thousand dollars to a few days depending on the size of the blade and the specificity.Surface coating is usually coated with titanium (such as titanium nitride, etc.)Large manufacturers such as diamond coating equipment general equipment in the tens of millions of yuan in cost is quite high, in Jiangsu there is a foreign company specialized in coating equipment sold to undertake external coating business, the coating cost with you a coated blade is related to the price from a few dollars to tens of dollars / piece / slice.

- Q: Carbide blade domestic that tricky point?

- Too much, there are at least dozens of domestic do this.

- Q: What is the difference between hard alloy and steel

- Cobalt (Co) is used in bonding in the alloy, is in the process of sintering, it can make the tungsten carbide (WC) powder and tightly surrounded Bonded together, after cooling, became hard alloy. (equivalent to the cement content). Usually: 3%--30% tungsten carbide (WC) is the main component of some metal properties of the hard alloy or cermet, the total composition of 70%---97% (weight ratio) is widely used in wear-resistant, high temperature resistance, resistance corrosion, bad working environment of the parts or tool, cutter tools.

- Q: Machining center 8 mm carbide cutter processing 45 steel, how to set the speed, feed, and moving speed?

- Faster, two RPM 1 mm, too fast, with G96 RPM feed 0.2 below

- Q: Explain from the materialGeneral modelIf you buy itWhat parameters are provided?

- Tungsten is on the hard alloy with tungsten carbide as the main (academic called tungsten based alloys), we called the daily hard alloy is usually tungsten based alloys, namely tungsten steel.

- Q: What is the coefficient of thermal expansion of cemented carbides?

- [classification of cemented carbide]1, tungsten cobalt carbide: the main component is tungsten carbide (WC) and binder cobalt (Co). The brand is from "YG" ("hard cobalt" Pinyin prefix) composition and percentage of average amount of cobalt.2, tungsten titanium cobalt carbide: the main components are tungsten carbide, titanium carbide (TiC) and cobalt. The grade by "YT" ("hard ti" Pinyin prefix) and the average content of titanium carbide.3, tungsten titanium tantalum (NB): hard alloy is the main component of tungsten carbide, titanium carbide, tantalum carbide (or niobium carbide) and cobalt. thisThis kind of hard alloy is also called universal cemented carbide or universal hard alloy. The grade by "YW" ("hard", "million" Pinyin prefix) and sequence number.

- Q: Carbide products which are used more?

- Sealing rings in the sealing industry, mould industry, machine tools, milling cutters, drill bits in the mining industry, and armor piercing shells in the army, etc.

- Q: One kind of steel is called T10, and another is carbon steel. What kind of hardness and strength do they have?

- Carbon steel is also divided into many kinds, the higher the carbon content, the greater the hardnessAlloy steel is also very many kinds of ah, what tungsten carbon alloy, chromium, manganese, molybdenum and so on a lot?It seems that Chinese steel is not of high qualityTechnology is not in place

- Q: How hard metal is welded with stainless steel?

- Braze welding can be used.Carbide containing tungsten, vanadium and other metals, melting point higher than stainless steel, can be considered

- Q: What is a hard alloy mixture?

- Tungsten carbide mainly consists of tungsten carbide + other small elements,

Send your message to us

FeSi Inoculant Used In Steel Making

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords